edit: You might have noticed this thread in the wrong section. I just realized project guidance is probably more appropriate for it.

So I originally started a quest on another thread a year ago:

http://forum.pjrc.com/threads/21682-Teensy-3-0-looking-for-ADC-absolute-measurement-tips-)

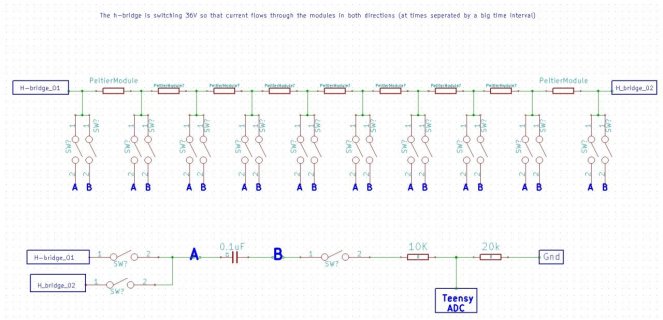

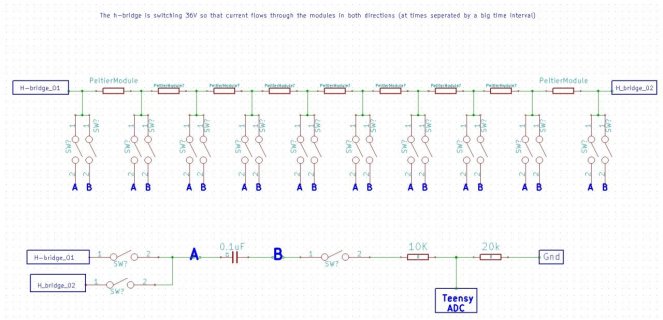

The scope of my challenge changed a little, and my leading plan of action has shifted. I realize that my question is no longer about precision voltage measurement on the ADC, because I'm not scaling the signal as much with resistors. Instead I am now trying to use a capacitor to measure my voltages, then switches to float the gnd of the capacitor and then connect it to gnd of the teensy, then connect the + of the capacitor to the ADC.

Originally that felt like mystique logic, but actually it kind of seems sensible now that I think more about what a capacitor is.

To quickly lay out the application I'm trying to make:

I have a 36V voltage running through an integrated H-bridge controlled by the Teensy. This voltage is applied through 9 peltier modules, which you can think of as resistors- sort of. Critically, I have to apply the voltage in two directions for the peltier module, first 0--36V, then 36V---0. I want to be able to measure the voltage across an individual peltier module, so that I can determine the rough DC resistance of that module and in turn its power consumption (since I know the current going through the total series circuit.) I intend on using a capacitor system to measure these voltages, to deal with the fact they vary as high as 36V above teensy-ground, even while the individual relative voltages are much less (about 4V max each).

But what I don't have enough experience with, is transistor logic. I have used both N and P-channel mosfets before, and NPN transistors. I think in this application because I am making a directional change in my voltages with 0----stuff to measure---36v then 36----stuff to measure---0v, I am dealing with negative voltages, and also moments when the relative voltage to ground of something is 33v, then later 3v. This totally messes up my limited understanding of how transistors functionally work.

I think the only solution I have is to use a lower-cost small SSR type chip like http://datasheet.octopart.com/G3VM-61H1-Omron-datasheet-9718722.pdf. I don't know if it will work as I intend, because I am in over my head by a little bit with transistor logic.

Presumably I can't just use mosfets because direction of the voltage will change, but perhaps I actually could still use a P-channel mosfet to switch the lines and another transistor to allow the teensy to switch the p-side. I will however struggle with getting the right Vgs voltage, since the circuit changes directions.

As draw in the attached circuit I've just show switch symbols, which does kind of point out that I could use a wonky series of low power relays if I'm desperate.

Thanks for any suggestions or input. At this point I'm mainly looking at two things

(1) Is this flying capacitor solution feasible? Am I missing something major?

(2) What can I use for the 'switches' in my circuit? So that I can control these things from the teensy.

View attachment 2605

So I originally started a quest on another thread a year ago:

http://forum.pjrc.com/threads/21682-Teensy-3-0-looking-for-ADC-absolute-measurement-tips-)

The scope of my challenge changed a little, and my leading plan of action has shifted. I realize that my question is no longer about precision voltage measurement on the ADC, because I'm not scaling the signal as much with resistors. Instead I am now trying to use a capacitor to measure my voltages, then switches to float the gnd of the capacitor and then connect it to gnd of the teensy, then connect the + of the capacitor to the ADC.

Originally that felt like mystique logic, but actually it kind of seems sensible now that I think more about what a capacitor is.

To quickly lay out the application I'm trying to make:

I have a 36V voltage running through an integrated H-bridge controlled by the Teensy. This voltage is applied through 9 peltier modules, which you can think of as resistors- sort of. Critically, I have to apply the voltage in two directions for the peltier module, first 0--36V, then 36V---0. I want to be able to measure the voltage across an individual peltier module, so that I can determine the rough DC resistance of that module and in turn its power consumption (since I know the current going through the total series circuit.) I intend on using a capacitor system to measure these voltages, to deal with the fact they vary as high as 36V above teensy-ground, even while the individual relative voltages are much less (about 4V max each).

But what I don't have enough experience with, is transistor logic. I have used both N and P-channel mosfets before, and NPN transistors. I think in this application because I am making a directional change in my voltages with 0----stuff to measure---36v then 36----stuff to measure---0v, I am dealing with negative voltages, and also moments when the relative voltage to ground of something is 33v, then later 3v. This totally messes up my limited understanding of how transistors functionally work.

I think the only solution I have is to use a lower-cost small SSR type chip like http://datasheet.octopart.com/G3VM-61H1-Omron-datasheet-9718722.pdf. I don't know if it will work as I intend, because I am in over my head by a little bit with transistor logic.

Presumably I can't just use mosfets because direction of the voltage will change, but perhaps I actually could still use a P-channel mosfet to switch the lines and another transistor to allow the teensy to switch the p-side. I will however struggle with getting the right Vgs voltage, since the circuit changes directions.

As draw in the attached circuit I've just show switch symbols, which does kind of point out that I could use a wonky series of low power relays if I'm desperate.

Thanks for any suggestions or input. At this point I'm mainly looking at two things

(1) Is this flying capacitor solution feasible? Am I missing something major?

(2) What can I use for the 'switches' in my circuit? So that I can control these things from the teensy.

View attachment 2605