Hi there!

I am working on a project for which I want a low-voltage cut-off to protect the battery pack. It's a power tool running off of a 12V battery pack. The Teensy is running behind a 5V voltage regulator.

So, as it is right now, the tool will run until the battery pack voltage drops down around 5 volts, then the voltage regulator stops working and the Teeny shuts off and shuts everything else down with it. That's no good, because the batteries should only be discharged down to a minimum of 9.54V (3.18V per cell).

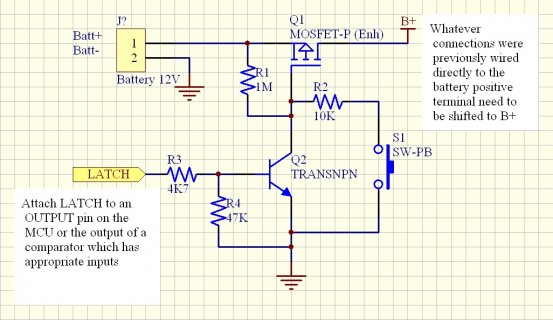

Is there any way to programmatically shut down the Teensy? I can make a voltage divider, hook it to a pin, and then have X happen once it drops below a minimum. If the Teensy can shut itself off, then X can be "turn off the Teensy!". Perfect!

If not, what would you electronics wizards recommend as a cheap, simple low-voltage cut-off method? Does someone sell a simple PCB for battery protection that will perform low-voltage cut-off? Or for all I know it would be relatively simple to put one together myself using a few components, perhaps? I'm reading on Wikipedia about it and trying to learn, but it's new ground for me and I'm not seeing a simple solution. Maybe a MOSFET with a 12V gate threshold? But that would have a small current pull even after it shuts off everything behind it, right? If so, that would slowly drain the battery to zero if the battery is left plugged in by the user and wreck it even worse than the current set-up, which at least stops drawing after 5V.

I am working on a project for which I want a low-voltage cut-off to protect the battery pack. It's a power tool running off of a 12V battery pack. The Teensy is running behind a 5V voltage regulator.

So, as it is right now, the tool will run until the battery pack voltage drops down around 5 volts, then the voltage regulator stops working and the Teeny shuts off and shuts everything else down with it. That's no good, because the batteries should only be discharged down to a minimum of 9.54V (3.18V per cell).

Is there any way to programmatically shut down the Teensy? I can make a voltage divider, hook it to a pin, and then have X happen once it drops below a minimum. If the Teensy can shut itself off, then X can be "turn off the Teensy!". Perfect!

If not, what would you electronics wizards recommend as a cheap, simple low-voltage cut-off method? Does someone sell a simple PCB for battery protection that will perform low-voltage cut-off? Or for all I know it would be relatively simple to put one together myself using a few components, perhaps? I'm reading on Wikipedia about it and trying to learn, but it's new ground for me and I'm not seeing a simple solution. Maybe a MOSFET with a 12V gate threshold? But that would have a small current pull even after it shuts off everything behind it, right? If so, that would slowly drain the battery to zero if the battery is left plugged in by the user and wreck it even worse than the current set-up, which at least stops drawing after 5V.

![IMG_3408[1].jpg IMG_3408[1].jpg](https://forum.pjrc.com/data/attachments/3/3290-187b909c34905c302f936ac7eee7979b.jpg)

![IMG_3410[1].jpg IMG_3410[1].jpg](https://forum.pjrc.com/data/attachments/3/3291-5f78cb32745427092e60c8c5abd805db.jpg)