You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Recommend a Proto/expansion brd for Teensy 2.0++

- Thread starter TonyA

- Start date

- Status

- Not open for further replies.

There is always the Radio Shack matching Printing Circuit Board (PCB). It has the same footprint and layout at their solderless breadboard. Develop on a solderless breadboard and then transfer over to the solderable PCB.

http://www.radioshack.com/product/i...ce=CAT&znt_medium=RSCOM&znt_content=CT2032230

http://www.radioshack.com/product/i...ce=CAT&znt_medium=RSCOM&znt_content=CT2032230

http://www.radioshack.com/product/i...ce=CAT&znt_medium=RSCOM&znt_content=CT2032230

http://www.radioshack.com/product/i...ce=CAT&znt_medium=RSCOM&znt_content=CT2032230

There is always the Radio Shack matching Printing Circuit Board (PCB). It has the same footprint and layout at their solderless breadboard. Develop on a solderless breadboard and then transfer over to the solderable PCB.

http://www.radioshack.com/product/i...ce=CAT&znt_medium=RSCOM&znt_content=CT2032230

http://www.radioshack.com/product/i...ce=CAT&znt_medium=RSCOM&znt_content=CT2032230

Thank you for the info and links, I appreciate it. I was thinking I might have to use a Radio Shack board as last resort.

Thanks again,

TonyA

PaulStoffregen

Well-known member

I use 3 different ways...

1: For quick & easy prototyping, nothing beats a solderless breadboard.

2: For simple/quick & rugged/permanent construction, I use pad-per-hole vector board and point-to-point soldering. The boards I use are some I had custom made years ago, when one of the PCB fab companies had a great 100 piece price and didn't care if it had too many holes (most won't honor low prices for making these boards). You can see them on many pages where I've tested Arduino libraries. For example:

http://www.pjrc.com/teensy/td_libs_Keypad.html

Back then, everyone had high prices on pad-per-hole vector boards. Recently there are a number of companies like iTead which have them very cheap. Here's one:

http://imall.iteadstudio.com/prototyping/protoboard/im120710002.html

The downside to point-to-point wiring is it's time consuming. I use Teflon insulated wire, which helps a lot since the plastic doesn't melt or shrink if you heat the wire too much while soldering. It costs more than normal wire, but the time saving is worthwhile.

3: For complex & rugged/permanent construction, laying out a custom PCB is the simplest way. Well, that's after you suffer the learning curve of the CAD software. Unfortunately, you can't have both fast and cheap. For fast, I use www.pcbexpress.com. For cheap, I usually use www.oshpark.com, but if the board is much larger than about 10 square inches and doesn't need the higher quality specs, I'll use iTead. But Oshpark's quality is much better. Sometimes using 6 mil traces and 13 min vias saves a lot of time routing the board and allows a smaller size, which makes oshpark even more attractive.

1: For quick & easy prototyping, nothing beats a solderless breadboard.

2: For simple/quick & rugged/permanent construction, I use pad-per-hole vector board and point-to-point soldering. The boards I use are some I had custom made years ago, when one of the PCB fab companies had a great 100 piece price and didn't care if it had too many holes (most won't honor low prices for making these boards). You can see them on many pages where I've tested Arduino libraries. For example:

http://www.pjrc.com/teensy/td_libs_Keypad.html

Back then, everyone had high prices on pad-per-hole vector boards. Recently there are a number of companies like iTead which have them very cheap. Here's one:

http://imall.iteadstudio.com/prototyping/protoboard/im120710002.html

The downside to point-to-point wiring is it's time consuming. I use Teflon insulated wire, which helps a lot since the plastic doesn't melt or shrink if you heat the wire too much while soldering. It costs more than normal wire, but the time saving is worthwhile.

3: For complex & rugged/permanent construction, laying out a custom PCB is the simplest way. Well, that's after you suffer the learning curve of the CAD software. Unfortunately, you can't have both fast and cheap. For fast, I use www.pcbexpress.com. For cheap, I usually use www.oshpark.com, but if the board is much larger than about 10 square inches and doesn't need the higher quality specs, I'll use iTead. But Oshpark's quality is much better. Sometimes using 6 mil traces and 13 min vias saves a lot of time routing the board and allows a smaller size, which makes oshpark even more attractive.

I use pad-per-hole vector board and point-to-point soldering. The boards I use are some I had custom made years ago, when one of the PCB fab companies had a great 100 piece price and didn't care if it had too many holes (most won't honor low prices for making these boards). You can see them on many pages where I've tested Arduino libraries. For example:

http://www.pjrc.com/teensy/td_libs_Keypad.html

Paul, How about part numbers or source for the plastic base and standoffs? Care to share the Gerbers for your custom board? Do you think OSH Park would manufacture?

PaulStoffregen

Well-known member

Those standoffs are Keystone 4800.

http://www.digikey.com/product-detail/en/4800/4800K-ND

The plastic base was laser cut at Techshop (back when they were in business in the Portland, Oregon area) from a sheet of scrap I bought at Tap Plastics. Sometimes I just cut the plastic on my table saw and drill the holes, if I need a different size. More work than having them pre-cut, but more flexible (unless of course in the case where you own a laser cutter or have regular access to a shop with one...... I do not, yet...)

I don't have the files for that old prototype board. Here's the gerbers for a newer design, which I'm using for most new projects. You'll probably see it in numerous photos I post. Of course, if you want a different size or shape, it's pretty simple to draw these in free CAD programs and send the files to places like iTead, DirtyPCB, etc.

OSH Park also sells a really nice one at a low $4 price. Their's has normal pads on both sides, rather than a ground plane on top like my design. That's actually better for some projects, because you don't have to worry about metal parts shorting to the top side, but it does mean a bit more work to wire the ground net. I have several of their's in my supply draw and use them for some projects.

http://www.digikey.com/product-detail/en/4800/4800K-ND

The plastic base was laser cut at Techshop (back when they were in business in the Portland, Oregon area) from a sheet of scrap I bought at Tap Plastics. Sometimes I just cut the plastic on my table saw and drill the holes, if I need a different size. More work than having them pre-cut, but more flexible (unless of course in the case where you own a laser cutter or have regular access to a shop with one...... I do not, yet...)

I don't have the files for that old prototype board. Here's the gerbers for a newer design, which I'm using for most new projects. You'll probably see it in numerous photos I post. Of course, if you want a different size or shape, it's pretty simple to draw these in free CAD programs and send the files to places like iTead, DirtyPCB, etc.

OSH Park also sells a really nice one at a low $4 price. Their's has normal pads on both sides, rather than a ground plane on top like my design. That's actually better for some projects, because you don't have to worry about metal parts shorting to the top side, but it does mean a bit more work to wire the ground net. I have several of their's in my supply draw and use them for some projects.

Attachments

PaulStoffregen

Well-known member

Here is a EPS drawing for the laser-cut base that matches "proto5x10".

Since Techshop went under (Portland only, they're alive in the Bay), I've been using BC Laserworks. They can cut pretty much any number of parts from that EPS file. You can send them material, or for common stuff like 1/4 inch acrylic, they can provide it and just ship the finished parts.

Since Techshop went under (Portland only, they're alive in the Bay), I've been using BC Laserworks. They can cut pretty much any number of parts from that EPS file. You can send them material, or for common stuff like 1/4 inch acrylic, they can provide it and just ship the finished parts.

Attachments

PaulStoffregen

Well-known member

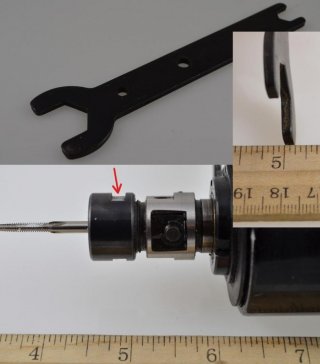

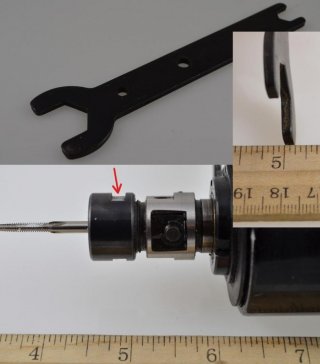

After the plastic is cut, I use this tool (on a drill press) to tap the threads in the holes. I got it used on Ebay for about $150.

Before I got that tool, I used to do it the very slow way with a tap handle, which you can get cheap at pretty much any hardware store.

Edit: I think this is where it can be purchased brand new.

http://www.use-enco.com/CGI/INSRIT?PARTPG=INSRAR2&PMAKA=291-5006&PMPXNO=8428564

Edit again: mine came from a surplus equipment place selling on ebay... without those extra accessories you see in the photo on Enco's site. This photo was asking for help finding the special wrench. It turns out they're widely available for bicycle repair, in case you get a used one that comes without the wrench needed to fasten the collet when you put a new tap bit in.

Before I got that tool, I used to do it the very slow way with a tap handle, which you can get cheap at pretty much any hardware store.

Edit: I think this is where it can be purchased brand new.

http://www.use-enco.com/CGI/INSRIT?PARTPG=INSRAR2&PMAKA=291-5006&PMPXNO=8428564

Edit again: mine came from a surplus equipment place selling on ebay... without those extra accessories you see in the photo on Enco's site. This photo was asking for help finding the special wrench. It turns out they're widely available for bicycle repair, in case you get a used one that comes without the wrench needed to fasten the collet when you put a new tap bit in.

Last edited:

- Status

- Not open for further replies.