reginalStetson

Active member

I'm developing software to interact with the plucking of a string on an electric guitar. I've decided to use the teensy 3.0 as an interface between the software and the guitar.

Here's what I need from the teensy: I need a reliable stream of data representing the plucking of a string and its gradual natural dampening. In other words, I need a smooth slope representing the intensity of the vibration of the string. Ideally, a '0' represents an idle string, while '1023' represents a string at its maximum vibration. (The 1023 will decay to 0 as the string naturally comes to rest.)

To implement this, I plan on interfacing an electric guitar pickup with the teensy. A pickup generates an AC voltage that varies depending on the vibration of the string.

I have two pickups that I'm experimenting with. The first has a resistance of 20k ohm and produces a maximum of about 0.25 volts. The second, 3.5k ohm with max 0.125 volts. I will have one pickup per string.

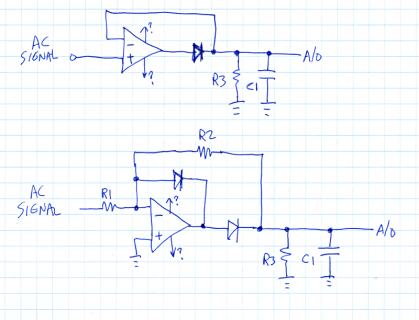

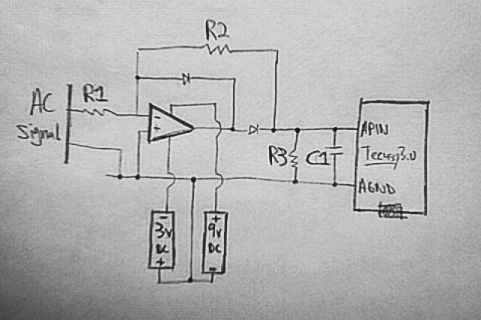

My design abstract:

Rectify the AC voltage from the pickup;

smooth it with a capacitor;

amplify it with an op-amp;

measure its voltage with an analog pin.

Here's where I need some help.

First of all, is this design feasible?

If so, I need some help with the specifics of the design, because I have not been able to make it functional with the experimenting that I've done so far.

I have a 741 op-amp, a 0.1uF capacitor, and several varieties of resistors. I also have a bridge rectifier.

I've attempted both inverting and non-inverting amplification with the op-amp with no success, and have also experimented with different values of feedback and input resistors with the op-amp.

My feeling is that I'm not using the ideal resistor and capacitor values for the smoothing and amplification of the signal. Or maybe it's that the design is wrong, which brings me to my next question.

If this design is not feasible, are there any suggestions on a different approach that I should be taking?

Here's what I need from the teensy: I need a reliable stream of data representing the plucking of a string and its gradual natural dampening. In other words, I need a smooth slope representing the intensity of the vibration of the string. Ideally, a '0' represents an idle string, while '1023' represents a string at its maximum vibration. (The 1023 will decay to 0 as the string naturally comes to rest.)

To implement this, I plan on interfacing an electric guitar pickup with the teensy. A pickup generates an AC voltage that varies depending on the vibration of the string.

I have two pickups that I'm experimenting with. The first has a resistance of 20k ohm and produces a maximum of about 0.25 volts. The second, 3.5k ohm with max 0.125 volts. I will have one pickup per string.

My design abstract:

Rectify the AC voltage from the pickup;

smooth it with a capacitor;

amplify it with an op-amp;

measure its voltage with an analog pin.

Here's where I need some help.

First of all, is this design feasible?

If so, I need some help with the specifics of the design, because I have not been able to make it functional with the experimenting that I've done so far.

I have a 741 op-amp, a 0.1uF capacitor, and several varieties of resistors. I also have a bridge rectifier.

I've attempted both inverting and non-inverting amplification with the op-amp with no success, and have also experimented with different values of feedback and input resistors with the op-amp.

My feeling is that I'm not using the ideal resistor and capacitor values for the smoothing and amplification of the signal. Or maybe it's that the design is wrong, which brings me to my next question.

If this design is not feasible, are there any suggestions on a different approach that I should be taking?