volatile int i = 0; //zero-point counter

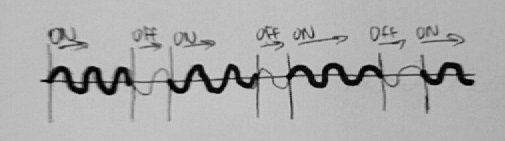

int cycleInterval1 = 7; //duty cycle interval 1

int cycleInterval2 = 11; //duty cycle interval 2

//(initial values of 7 and 11 will

//default the on/off cycle to 70% duty)

void setup(){

Serial.begin(28800); //begin serial communication

pinMode(1, OUTPUT); //connected to SSR TRIAC

pinMode(7, INPUT_PULLUP); //connected to hall sensor

attachInterrupt //interrupt at zero-point

(0, atZeroPoint, RISING); //pin connected to zero-point detector

attachInterrupt //interrupt when hall sensor is activated

(7, atHallPass, FALLING); //pin connected to hall effect sensor

}

void atZeroPoint(){ //function called at each zero-point

i++; //increment counter

}

void atHallPass(){ //function called at each hall-pass

Serial.print(1, BIN); //message indicating revolution complete

}

void loop(){

if(i == 1){ //at first zero-point:

digitalWrite(1, HIGH); //send voltage to TRIAC

}

if(i == cycleInterval1){ //if interval 1 is reached:

delay(1); //(TRIAC on for remainder of half-cycle)

digitalWrite(1, LOW); //cease voltage to TRIAC

}

if(i == cycleInterval2){ //if interval 2 is reached:

i = 1; //reset counter to one (restart on/off cycle)

}

if(Serial.available() == 2){ //if two messages exist in buffer:

cycleInterval1 = Serial.read(); //set the first to interval 1

cycleInterval2 = Serial.read(); //set the second to interval 2

i = 0; //restart on/off cycle

}

}