synfinatic

Active member

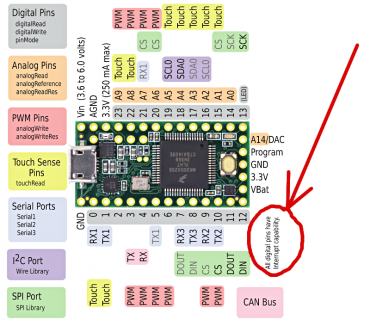

I'm looking at building a project using a Teensy 3.1/3.2 with 4-12 Melexis MLX90614 IR temp sensors. The sensors support SMBus (I2C) as well as PWM output, but I'd like to use the PWM mode since it means I won't have to assign a unique slave ID for each sensor and means I can read the temperatures constantly.

The challenge of course is with that many PWM inputs going all at once, I'd definitely need to be using interrupts to measure the signal. I thought there was information about the number of pins with interrupts on the Teensy 3.1 on the PJRC website, but I can't find it anymore??? Would love to figure out which digital pins support interrupts.

Thanks!

The challenge of course is with that many PWM inputs going all at once, I'd definitely need to be using interrupts to measure the signal. I thought there was information about the number of pins with interrupts on the Teensy 3.1 on the PJRC website, but I can't find it anymore??? Would love to figure out which digital pins support interrupts.

Thanks!