Hi,

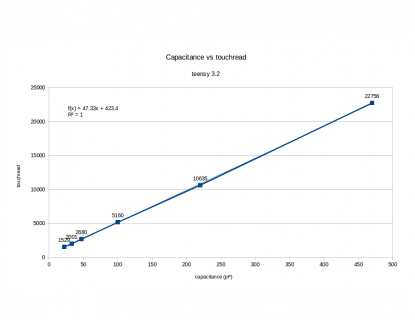

I was expecting the touchRead() to perform according to a RC time circuit but it seems to do exactly the opposite... I understood that the actual number that is displayed should come close to the actual capacitance in Farad (or a denomination of it).

I understood that the actual number that is displayed should come close to the actual capacitance in Farad (or a denomination of it).

Now, when I feed it an RC time circuit, variable resistor (1-50Kohm) and ceramic capacitor (100nF) and slowly turn down to Ohms I see the number returned from touchRead() increase. Where I expected it to decrease, less resistance equals faster charging cycles... When I used the same circuit and did a "normal" RC time measurment using a regular GPIO I got the expected result.

How does touchRead() work?

Kind regards,

Aduen

I was expecting the touchRead() to perform according to a RC time circuit but it seems to do exactly the opposite...

Now, when I feed it an RC time circuit, variable resistor (1-50Kohm) and ceramic capacitor (100nF) and slowly turn down to Ohms I see the number returned from touchRead() increase. Where I expected it to decrease, less resistance equals faster charging cycles... When I used the same circuit and did a "normal" RC time measurment using a regular GPIO I got the expected result.

How does touchRead() work?

Kind regards,

Aduen