Hi,

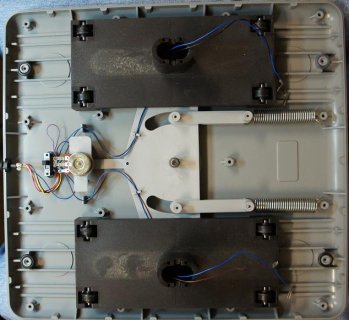

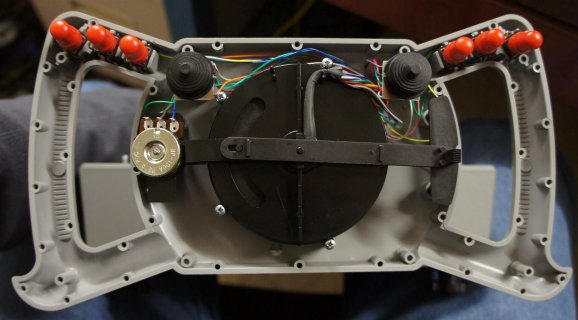

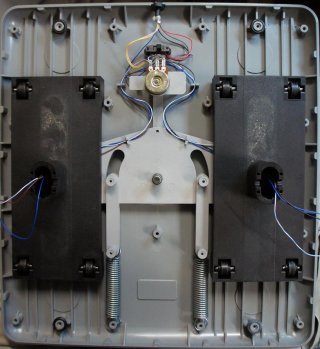

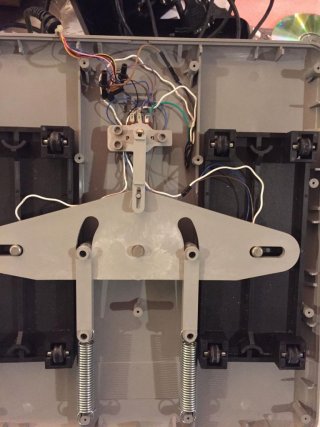

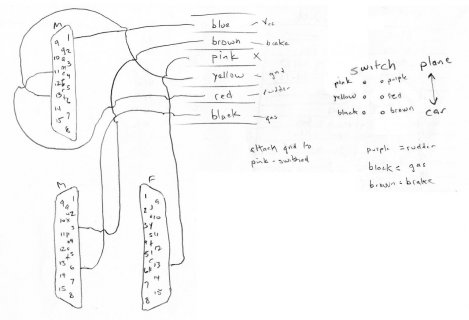

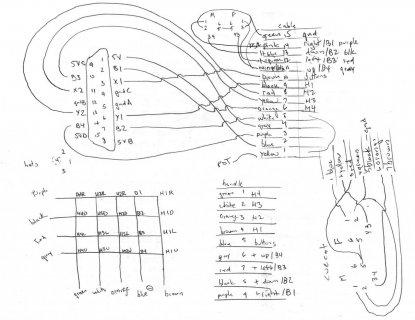

I’ve got an old CH Products Virtual Pilot Pro yoke and Pro Pedals here, and they use the old gameport interface.

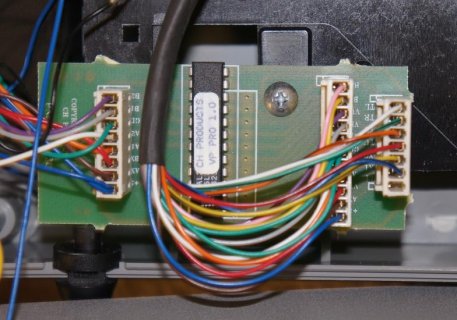

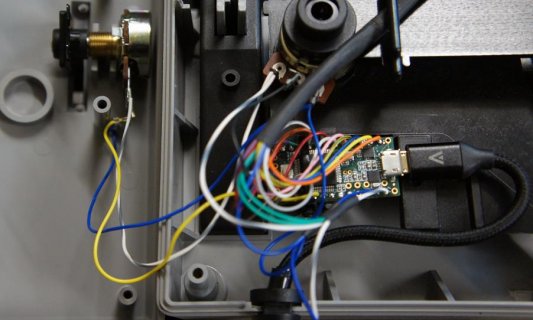

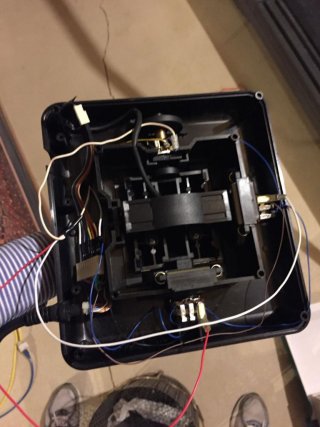

I was originally going to put a Teensy inside the chassis of each, wired directly to the potentiometers and buttons. For the potentiometers (of which there is one per axis), I was going to connect one end of the pot to 3.3V, the other end to AGND and the wiper to an Analog Pin. (Essentially I would copy this approach)

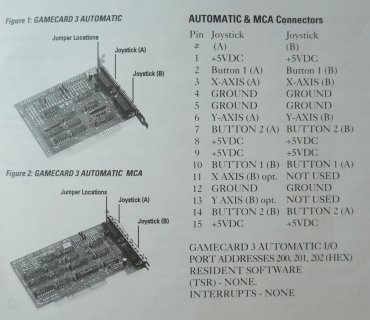

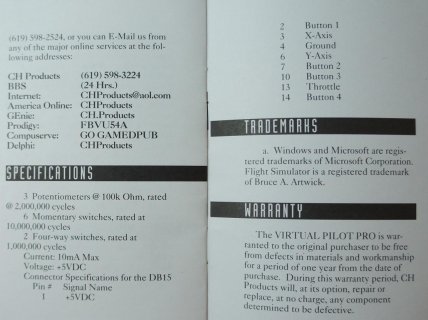

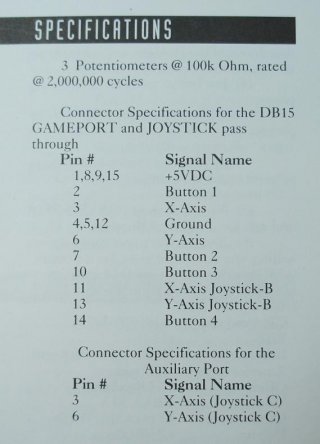

But then I found out from this page that I could interface the yoke and pedals with the Teensy without modifying them, because apparently gameport joysticks “use their potentiometers as voltage dividers – this means you need to add a 100kΩ resistor between the Teensy pin and ground” for each axis.

So whereas I was thinking I would need to put one Teensy in the yoke chassis and a second Teensy in the pedals chassis, modifying the units as necessary, now I think I’d prefer to get some gameport style sockets and connect them to just one Teensy inside an enclosure, with the yoke and pedals unmodified, simply plugging in as they did with a PC in the 1990s.

So my question is, which approach is better in your opinion?

I have no problem with modifying the yoke and pedals if it’s the better approach but if the precision etc. will be the same (or not noticeably different) if I build an interface box, then I’d rather do that.

(Plus I already have a spare enclosure and stripboard that I think would be suitable)

I already have two Teensy 3.2s ready for this project, but if I only have to use one that would be useful. These things are awesome.

I'd really appreciate your guidance before I sacrifice quality just to save a bit of effort and money, thanks!

I’ve got an old CH Products Virtual Pilot Pro yoke and Pro Pedals here, and they use the old gameport interface.

I was originally going to put a Teensy inside the chassis of each, wired directly to the potentiometers and buttons. For the potentiometers (of which there is one per axis), I was going to connect one end of the pot to 3.3V, the other end to AGND and the wiper to an Analog Pin. (Essentially I would copy this approach)

But then I found out from this page that I could interface the yoke and pedals with the Teensy without modifying them, because apparently gameport joysticks “use their potentiometers as voltage dividers – this means you need to add a 100kΩ resistor between the Teensy pin and ground” for each axis.

So whereas I was thinking I would need to put one Teensy in the yoke chassis and a second Teensy in the pedals chassis, modifying the units as necessary, now I think I’d prefer to get some gameport style sockets and connect them to just one Teensy inside an enclosure, with the yoke and pedals unmodified, simply plugging in as they did with a PC in the 1990s.

So my question is, which approach is better in your opinion?

I have no problem with modifying the yoke and pedals if it’s the better approach but if the precision etc. will be the same (or not noticeably different) if I build an interface box, then I’d rather do that.

(Plus I already have a spare enclosure and stripboard that I think would be suitable)

I already have two Teensy 3.2s ready for this project, but if I only have to use one that would be useful. These things are awesome.

I'd really appreciate your guidance before I sacrifice quality just to save a bit of effort and money, thanks!