Hi all,

I am very new to MCU and electronics and this this is my first post in this forum so I apologise in advance if this may seem a very basic question.

I am developing a Teensy 3.1 solution to use a Toroidal CT whereby I need to measure Frequency, Current and Voltage from the external system.

The frequencies I need to measure are all in the audio spectrum 20Hz - 20KHz (approx)

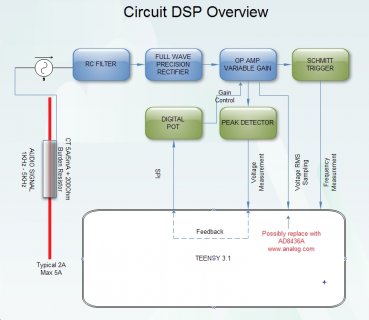

I push the signal from the current CT into my Digital signal processing electronics whereby a Schmitt trigger provides the nice waveform from the ugliest of input waveforms thereby allowing the MCU to successfully monitor the frequency.

My issue is over measuring the Current as this will range from 1mV to 500mv where 500mV = 5A.

If i understand things correctly I really need to bring the 500mV signal to the max of the AREF of the ADC.

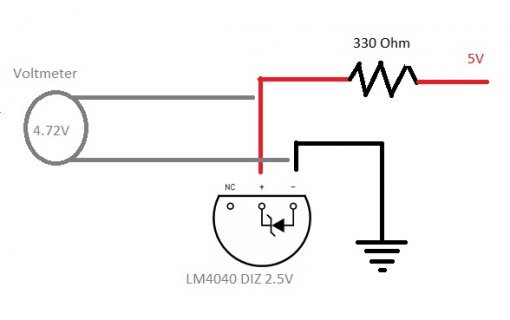

I could use a trimmer to on the AREF to compensate for PSU fluctuations, or use the Internal ref which i believe is 1.195V on the Teensy 3.1.

The preferable option i believe is to use an external voltage reference chip which cannot be more than the Teensy 3.1 power supply according to the post. https://www.pjrc.com/teensy/adc.html

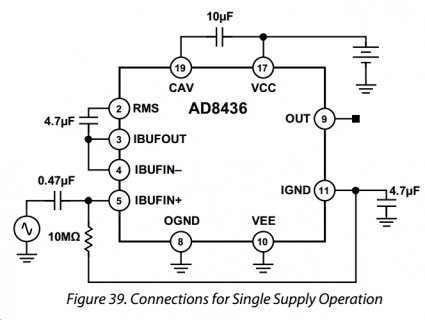

I would like to make the AREF as large as possible and use an op amp to offer the signal at its max level. I will also use a precision full wave rectifier op amp to offer the signal as a positive signal only to avoid the need for a rail to rail supply op amp and allow me to perform an RMS sample.

I have a couple of questions

1) What is the largest value for a precision voltage chip i can use to apply to AREF? Assume i am powering the Vin on the Teensy with a 5V regulator.

2) Can I simply connect the output from this voltage reference directly to the AREF or do i need to cut any PCB pads first. (I cant find a simple diagram that shows me how to do this)

3) Could I use a low AREF and use a MCU controlled (SPI) variable gain op amp (or digital pot) to offer all signals to the ADC at a higher level (maybe important for the 1mv signal) and then scale back by the gain applied.

4) Am I over complicating this task. I "simply" need the best accuracy possible.

Any advice or guidance from the experts would be gratefully appreciated.

thank you and apologies for my noob questions.

I am very new to MCU and electronics and this this is my first post in this forum so I apologise in advance if this may seem a very basic question.

I am developing a Teensy 3.1 solution to use a Toroidal CT whereby I need to measure Frequency, Current and Voltage from the external system.

The frequencies I need to measure are all in the audio spectrum 20Hz - 20KHz (approx)

I push the signal from the current CT into my Digital signal processing electronics whereby a Schmitt trigger provides the nice waveform from the ugliest of input waveforms thereby allowing the MCU to successfully monitor the frequency.

My issue is over measuring the Current as this will range from 1mV to 500mv where 500mV = 5A.

If i understand things correctly I really need to bring the 500mV signal to the max of the AREF of the ADC.

I could use a trimmer to on the AREF to compensate for PSU fluctuations, or use the Internal ref which i believe is 1.195V on the Teensy 3.1.

The preferable option i believe is to use an external voltage reference chip which cannot be more than the Teensy 3.1 power supply according to the post. https://www.pjrc.com/teensy/adc.html

I would like to make the AREF as large as possible and use an op amp to offer the signal at its max level. I will also use a precision full wave rectifier op amp to offer the signal as a positive signal only to avoid the need for a rail to rail supply op amp and allow me to perform an RMS sample.

I have a couple of questions

1) What is the largest value for a precision voltage chip i can use to apply to AREF? Assume i am powering the Vin on the Teensy with a 5V regulator.

2) Can I simply connect the output from this voltage reference directly to the AREF or do i need to cut any PCB pads first. (I cant find a simple diagram that shows me how to do this)

3) Could I use a low AREF and use a MCU controlled (SPI) variable gain op amp (or digital pot) to offer all signals to the ADC at a higher level (maybe important for the 1mv signal) and then scale back by the gain applied.

4) Am I over complicating this task. I "simply" need the best accuracy possible.

Any advice or guidance from the experts would be gratefully appreciated.

thank you and apologies for my noob questions.

Last edited: