PaulStoffregen

Well-known member

Wow. That's an expensive way to make circuit boards! As a student with a limited budget, why not just learn to use Eagle yourself? Yes, Eagle is a terrible program in many ways, but lots of hobbyists learn to use it fairly well. There's lots of tutorials and info online. There are now several low-cost PCB services like OSH Park, iTead, Seeed Studios, which aren't free, but they make this sort of thing much more affordable if you can learn Eagle, as most hobbyists do these days.

About the design, again, I'm afraid I have only bad news. It obviously is not robust enough. You're going to have to change the hardware. The fact you've already spent so much time and money has no influence on the electrons. Only improving circuity is going to fix this project.

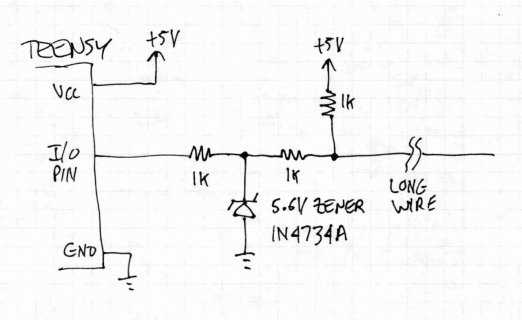

Even my prior suggestion may not be enough. From those photos, it appears you're running some of the pins from a Teensy++ 2.0 directly into a lengthy cable, spanning across a car with an ignition system and perhaps other noisy electronics. The cable goes at least to a display and 4 buttons. It appears to have another jack which might allow another cable to plug in?

This thing looks like some sort of tachometer. If so, I would be really cautious about running any cable into the engine area. Certainly you don't want to directly connect any microcontroller pin into that space. Even the ground wire connected to the microcontroller should probably not enter that space. If you're sensing the spark plugs somehow, whatever type sensor you're using will need some way to be isolated from the system or at least not cause a terrible ground loop current.

While I really do want to help you, there's a limit to what I can do... even if you're willing and able to afford to really try stuff. There's also a practical limit to the tech support I can provide. I'd say this thread and probably several emails I've answered are far beyond the normal support for Teensy... which is essentially what I call "get up and running", and perhaps addressing Arduino compatibility issues (which technically aren't Teensy issues, but Teensy does aim for best possible compatibility with all Arduino libraries and programs, so when people discover issues, I try to fix or address them somehow).

I can offer some advice, as can others on this forum. But ultimately, none of that will ever help if you can't revise the hardware to improve its robustness. Again, I'm really sorry this has gone so badly for you, and you've wracked up some debt without a sale-able product to show for it. But only a hardware redesign, probably based one some serious troubleshooting and experimenting with alternate approaches, is going to address these electrical problems. Ultimately it's about electrons in wires.

About the design, again, I'm afraid I have only bad news. It obviously is not robust enough. You're going to have to change the hardware. The fact you've already spent so much time and money has no influence on the electrons. Only improving circuity is going to fix this project.

Even my prior suggestion may not be enough. From those photos, it appears you're running some of the pins from a Teensy++ 2.0 directly into a lengthy cable, spanning across a car with an ignition system and perhaps other noisy electronics. The cable goes at least to a display and 4 buttons. It appears to have another jack which might allow another cable to plug in?

This thing looks like some sort of tachometer. If so, I would be really cautious about running any cable into the engine area. Certainly you don't want to directly connect any microcontroller pin into that space. Even the ground wire connected to the microcontroller should probably not enter that space. If you're sensing the spark plugs somehow, whatever type sensor you're using will need some way to be isolated from the system or at least not cause a terrible ground loop current.

While I really do want to help you, there's a limit to what I can do... even if you're willing and able to afford to really try stuff. There's also a practical limit to the tech support I can provide. I'd say this thread and probably several emails I've answered are far beyond the normal support for Teensy... which is essentially what I call "get up and running", and perhaps addressing Arduino compatibility issues (which technically aren't Teensy issues, but Teensy does aim for best possible compatibility with all Arduino libraries and programs, so when people discover issues, I try to fix or address them somehow).

I can offer some advice, as can others on this forum. But ultimately, none of that will ever help if you can't revise the hardware to improve its robustness. Again, I'm really sorry this has gone so badly for you, and you've wracked up some debt without a sale-able product to show for it. But only a hardware redesign, probably based one some serious troubleshooting and experimenting with alternate approaches, is going to address these electrical problems. Ultimately it's about electrons in wires.