EDIT; The scope of this thread changed, and I realized I should split the threads. The original thread was asking for basic ADC tips because I was looking to use a resistor ladder in a measurement application where I desired some accuracy. Later, I moved towards a solution that does not require as much resolution, but instead deals with transistor switching logic and flying capacitors. I do still need some advice on that, if anyone is willing http://forum.pjrc.com/threads/26516...witching-advice-many-thanks?p=53767#post53767. But I realized I should delineate the threads because the scope is very different, but the original thread [this one] still has some great advice for the original idea. Thank you for reading!

Hello! I'm a ME student and not entirely knowledgeable about signals.

The general point of my thread is that:

I am going to use my Teensy 3.0 to measure 18 voltages in series, of about 1.4V and 2.8V (after a divider), hopefully to #.## accuracy & resolution. Ultimately, the exact values don't matter as much as the relative accuracy between the 18 voltages. On the digital scale, I have a fairly large amount of time to take these measurements; 1-2 seconds would be a fair amount of time for the process to take. I'm hoping to learn some tips and things to understand about voltage measurements, so that I can make this setup with some chance of reasonable measurements.

The bigger picture of my system:

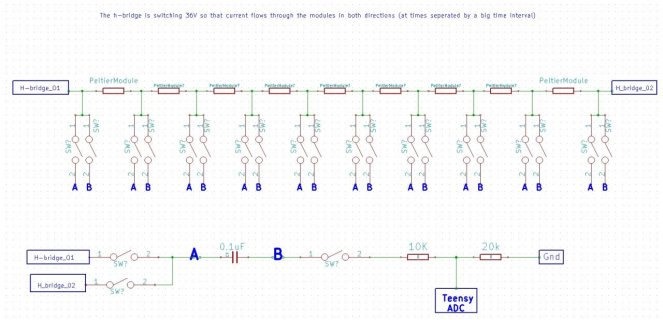

The teensy will be controlling about 3A and 42V through 18 modules in series a foot or two away from the teensy. I'll be using a DC integrated H-bridge to periodically (every 30 minutes) reverse the voltage direction. Since I can't measure 42V, or any of the voltages (it's 42-IR1-IR2-IR3-IR4 for each module in series), at each module tap I'll need a resistor divider. This divider will be calibrated in the software; since this is a one-time or two-time thing it's not a big deal to borrow a high quality meter and calibrate the resistor dividers.

I will also need to have a second stage scale that takes the voltages from the dividers, to get a positive reading from the negative voltage. Meaning, (Vreading[sometimes negative]) --- R1 ----MEASURE --- R1 ---- Vref. And knowing Vref, and my measurement, I should be able to calculate Vreading, which is half of the times a negative voltage. Before this stage, I will have a buffer op-amp, because the signals coming from the resistor dividers will be fairly high impedance. I am also thinking about using transistors to direct the voltages from the dividers to the { opamp+ negative voltage scaling component.} The reason for this is that it's easier & cheaper for me to have 18 transistors, than it is to have 18 sets of opamps, references, and scaling systems.

(sidenote, I'll be doing these measurements at certain temperatures, measured with a temp meter, and do certain calculations, and then hopefully print them out with a thermal printer.)

What I've considered so far:

Use a dedicated reference voltage for the ADC. Be very serious about this. (I read this on the forums)

Even though you have a dedicated reference voltage, make sure to substantially filter the teensy power from the 42v switched mode supply. (read this on this forum)

Add a 0.1uF cap on the voltage measurement (maybe this is not needed, since I have a cap?) (read on different forum)

*Pay attention to whatever other suggests people offer.* (will be doing)

I've also considered, and rejected:

Floating capacitor measurements to bypass the resistor divider. I don't quite understand enough of the theory of a floating capacitor voltage, despite the effort at learning and the fact it sounds reasonable in theory...I just dont quite understand if it actually works.

Inverting voltage ICs (I can't find enough information for the newb to learn)

Inverting op amps (complicated and only gaining 1 bit of resolution, by avoiding the 1:1 scale. Introduces complexity of using diodes, which I still haven't found out if their voltage drop is consistent/accurate.)

Other potential solutions that I dont know enough about...(also rejected.)

My reasons for hoping I'll get the accuracy I want.

Assume we have a Vref of 3v. At 14 bit resolution (assume I can get that much from teensy, because I can take slow measurements), I have 16384 steps. That's 0.000183V. Double that because of the negative to positive scaling. Then multiply it by 15 because we have a big voltage scaling for some of the measurements. So my resolution would be 0.00549V....and I only care about x.xx....So by my newbie rationale, I might be ok with resolution, as long as I can sort the potential accuracy problems.

What's left:

Please fill in the gaps. Let me know if there are things I should think about on my pcb (don't keep things too tight? Besides that? Have a ground plane? Besides that?)

I suspect that what I'm asking to do, merely because I have a reasonable amount of time to do it, is not new to anyone familiar with electronics. My solution might not be the perfect one, but it seems to be the best solution for me, after considering some other options. But I'm here to find out if there are any glaring problems to my plan, before I invest the many more hours it will take me to get further.

Hello! I'm a ME student and not entirely knowledgeable about signals.

The general point of my thread is that:

I am going to use my Teensy 3.0 to measure 18 voltages in series, of about 1.4V and 2.8V (after a divider), hopefully to #.## accuracy & resolution. Ultimately, the exact values don't matter as much as the relative accuracy between the 18 voltages. On the digital scale, I have a fairly large amount of time to take these measurements; 1-2 seconds would be a fair amount of time for the process to take. I'm hoping to learn some tips and things to understand about voltage measurements, so that I can make this setup with some chance of reasonable measurements.

The bigger picture of my system:

The teensy will be controlling about 3A and 42V through 18 modules in series a foot or two away from the teensy. I'll be using a DC integrated H-bridge to periodically (every 30 minutes) reverse the voltage direction. Since I can't measure 42V, or any of the voltages (it's 42-IR1-IR2-IR3-IR4 for each module in series), at each module tap I'll need a resistor divider. This divider will be calibrated in the software; since this is a one-time or two-time thing it's not a big deal to borrow a high quality meter and calibrate the resistor dividers.

I will also need to have a second stage scale that takes the voltages from the dividers, to get a positive reading from the negative voltage. Meaning, (Vreading[sometimes negative]) --- R1 ----MEASURE --- R1 ---- Vref. And knowing Vref, and my measurement, I should be able to calculate Vreading, which is half of the times a negative voltage. Before this stage, I will have a buffer op-amp, because the signals coming from the resistor dividers will be fairly high impedance. I am also thinking about using transistors to direct the voltages from the dividers to the { opamp+ negative voltage scaling component.} The reason for this is that it's easier & cheaper for me to have 18 transistors, than it is to have 18 sets of opamps, references, and scaling systems.

(sidenote, I'll be doing these measurements at certain temperatures, measured with a temp meter, and do certain calculations, and then hopefully print them out with a thermal printer.)

What I've considered so far:

Use a dedicated reference voltage for the ADC. Be very serious about this. (I read this on the forums)

Even though you have a dedicated reference voltage, make sure to substantially filter the teensy power from the 42v switched mode supply. (read this on this forum)

Add a 0.1uF cap on the voltage measurement (maybe this is not needed, since I have a cap?) (read on different forum)

*Pay attention to whatever other suggests people offer.* (will be doing)

I've also considered, and rejected:

Floating capacitor measurements to bypass the resistor divider. I don't quite understand enough of the theory of a floating capacitor voltage, despite the effort at learning and the fact it sounds reasonable in theory...I just dont quite understand if it actually works.

Inverting voltage ICs (I can't find enough information for the newb to learn)

Inverting op amps (complicated and only gaining 1 bit of resolution, by avoiding the 1:1 scale. Introduces complexity of using diodes, which I still haven't found out if their voltage drop is consistent/accurate.)

Other potential solutions that I dont know enough about...(also rejected.)

My reasons for hoping I'll get the accuracy I want.

Assume we have a Vref of 3v. At 14 bit resolution (assume I can get that much from teensy, because I can take slow measurements), I have 16384 steps. That's 0.000183V. Double that because of the negative to positive scaling. Then multiply it by 15 because we have a big voltage scaling for some of the measurements. So my resolution would be 0.00549V....and I only care about x.xx....So by my newbie rationale, I might be ok with resolution, as long as I can sort the potential accuracy problems.

What's left:

Please fill in the gaps. Let me know if there are things I should think about on my pcb (don't keep things too tight? Besides that? Have a ground plane? Besides that?)

I suspect that what I'm asking to do, merely because I have a reasonable amount of time to do it, is not new to anyone familiar with electronics. My solution might not be the perfect one, but it seems to be the best solution for me, after considering some other options. But I'm here to find out if there are any glaring problems to my plan, before I invest the many more hours it will take me to get further.

Last edited: