Hi,

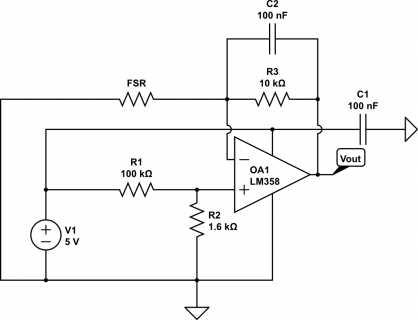

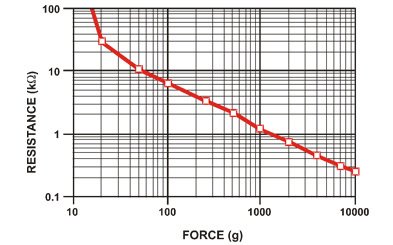

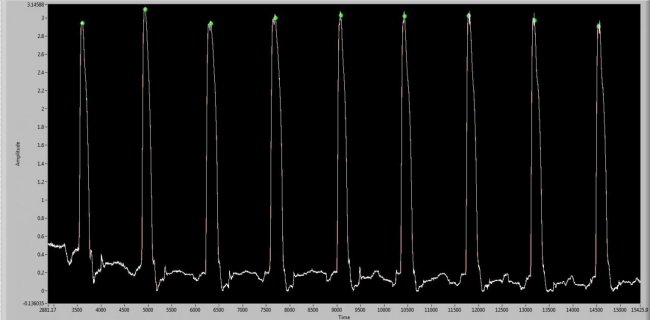

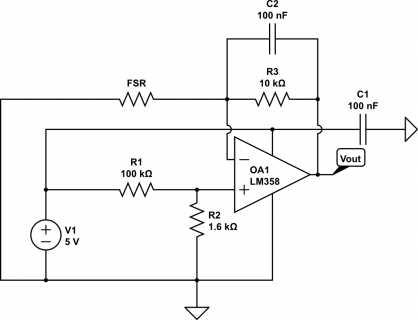

I am working on a project where I need to measure heel strike while walking. A cheap and simple way is to use an FSR, however I am having issues with getting a clean signal. Below is an image of my circuit diagram that is giving me a linear output (resistance of FSR does not change in a linear function), however one issue is the noise, which was greatly reduced using a 100nf cap between the negative input and output. The other issue is that the voltage offset is around 80mv, where I would like it to be closer to zero. I am using the lm358, just because it is what I had, plus I don't know enough about what op amp I need. I am just looking for some feedback on if my circuit is actually correct and if there is better op amp out there that will suit my needs. Thanks.

I am working on a project where I need to measure heel strike while walking. A cheap and simple way is to use an FSR, however I am having issues with getting a clean signal. Below is an image of my circuit diagram that is giving me a linear output (resistance of FSR does not change in a linear function), however one issue is the noise, which was greatly reduced using a 100nf cap between the negative input and output. The other issue is that the voltage offset is around 80mv, where I would like it to be closer to zero. I am using the lm358, just because it is what I had, plus I don't know enough about what op amp I need. I am just looking for some feedback on if my circuit is actually correct and if there is better op amp out there that will suit my needs. Thanks.