Project thread here:

http://forum.pjrc.com/threads/24370...ng-for-a-quot-sanity-check-quot-and-a-answers

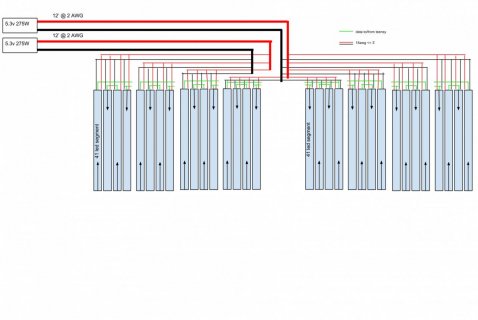

I have tried every combination of fixes suggested here on the forums, yet am still plagued with flicker issues. about 1/3 of the strips tend to flicker. I can get WHICH strips flicker to change based on how things are grounded, what resistors I use (if any), how power is distributed (4 teensys, 6 PSUs, 30 strips [120 segments] == lots of options), etc, but I feel like I'm just in over my head and flailing with trial and error.

All I can determine with my DMM is that 6' to 15' of 16AWG wire appears to reduce voltage from 5.15V at the PSU to 3.98V-4.18V at strips, but that any of the strips work OK with that voltage by themselves :-/ Beyond that, I just don't know how to properly diagnose what's wrong. Do i have to invest in a scope to do meaningful diagnosis or is there more testing I should be doing on my own? Changing grounding points or teensy-to-PSU alignment causes changes in behavior, but I don't know how to interpret those changes to effect a solution.

http://forum.pjrc.com/threads/24370...ng-for-a-quot-sanity-check-quot-and-a-answers

I have tried every combination of fixes suggested here on the forums, yet am still plagued with flicker issues. about 1/3 of the strips tend to flicker. I can get WHICH strips flicker to change based on how things are grounded, what resistors I use (if any), how power is distributed (4 teensys, 6 PSUs, 30 strips [120 segments] == lots of options), etc, but I feel like I'm just in over my head and flailing with trial and error.

All I can determine with my DMM is that 6' to 15' of 16AWG wire appears to reduce voltage from 5.15V at the PSU to 3.98V-4.18V at strips, but that any of the strips work OK with that voltage by themselves :-/ Beyond that, I just don't know how to properly diagnose what's wrong. Do i have to invest in a scope to do meaningful diagnosis or is there more testing I should be doing on my own? Changing grounding points or teensy-to-PSU alignment causes changes in behavior, but I don't know how to interpret those changes to effect a solution.