I'm working on a frequency measuring project for a modular synthesizer, using FreqMeasure and FreqCount libraries on a Teensy 2.0. Since I now have a multimeter that claims frequency measurement from 10Hz to 400Mhz +/-(0.01%+8) (UT71C) and since I also have voltage/current/resistance/frequency standard (see below) to check those claims, I was wondering where on Teensy 2.0 to measure the exact crystal frequency.

Given the pair of small capacitors around the crystal itself, I assume that putting probes directly there would be a bad idea, at minimum altering the frequency and possibly doing damage. Should I instead run some code that toggles an output pin such that it depends directly on the crystal frequency, measure that, and calculate the crystal from that? Or I guess, build the unit, have it measure the two frequency standards and calculate a correction factor from that. (Amazing how explaining a problem clearly for a forum posting often leads to the actual answer. But I'm going to go ahead and post anyway). Suggestions welcome.

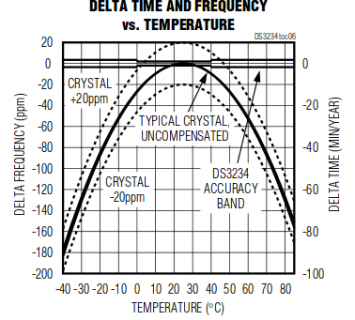

My project will use two Teensy 2.0, one handling the user interface (buttons, display, input switching, calculating derived values) and also temperature measurement and oven control; the second will be in a constant temperature oven with a separate, highly regulated power supply to minimise voltage-related and temperature-related fluctuations. But the absolute value of the crystal (at that temperature and with that supply) still needs to be measured. (The temperature probe is a Dallas DS18B20 One Wire Digital Temperature Sensor and the display is the Adafruit 0.96" 128x64 OLED which has been recently discussed in these forums, regarding use with hardware SPI on Teensy 3.0. This will be a Eurorack module).

The standard reference I mentioned is the DMM Check Plus by voltagestandard.com. In addition to using burned-in, high quality components it also comes with an individual measurements sheet, measured with an in-calibration HP 3458A and, for the frequency, an Agilent 53220A.

My particular DMM Check Plus unit has two frequencies, 439.968356 Hz and 7.042592 kHz.

Given the pair of small capacitors around the crystal itself, I assume that putting probes directly there would be a bad idea, at minimum altering the frequency and possibly doing damage. Should I instead run some code that toggles an output pin such that it depends directly on the crystal frequency, measure that, and calculate the crystal from that? Or I guess, build the unit, have it measure the two frequency standards and calculate a correction factor from that. (Amazing how explaining a problem clearly for a forum posting often leads to the actual answer. But I'm going to go ahead and post anyway). Suggestions welcome.

My project will use two Teensy 2.0, one handling the user interface (buttons, display, input switching, calculating derived values) and also temperature measurement and oven control; the second will be in a constant temperature oven with a separate, highly regulated power supply to minimise voltage-related and temperature-related fluctuations. But the absolute value of the crystal (at that temperature and with that supply) still needs to be measured. (The temperature probe is a Dallas DS18B20 One Wire Digital Temperature Sensor and the display is the Adafruit 0.96" 128x64 OLED which has been recently discussed in these forums, regarding use with hardware SPI on Teensy 3.0. This will be a Eurorack module).

The standard reference I mentioned is the DMM Check Plus by voltagestandard.com. In addition to using burned-in, high quality components it also comes with an individual measurements sheet, measured with an in-calibration HP 3458A and, for the frequency, an Agilent 53220A.

My particular DMM Check Plus unit has two frequencies, 439.968356 Hz and 7.042592 kHz.