brianchasalow

Member

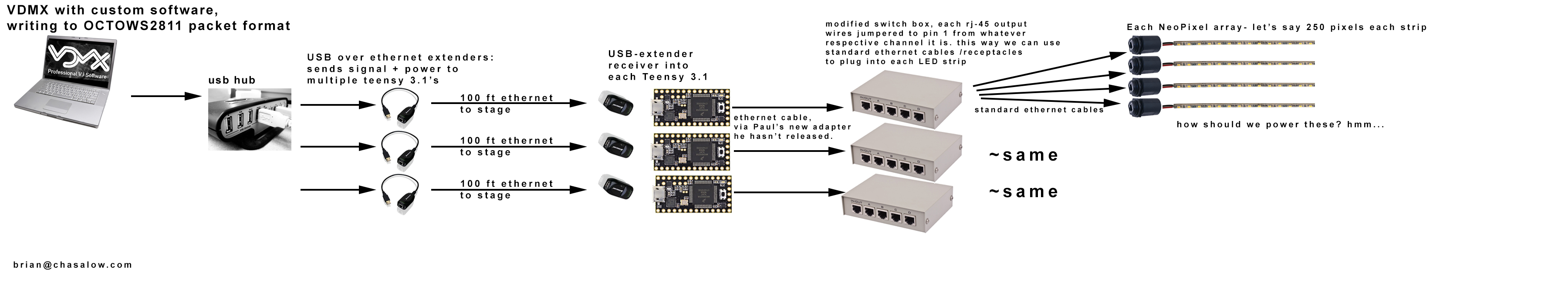

Hey there! I'm considering building a large LED setup for stage use for video. I was hoping to sit a computer near the teensy 3.1's, and just running signal + power to the stage. What's the maximum number of LED strips that I could place on a single line where I could safely achieve realtime video playback? I saw the following note:

"Driving 8 LED strips simultaneously allows each strip to be only 1/8th the length. All LEDs update 8X faster than driving only a single long strip. 1000 LEDs can be updated in 3.8 ms, which allows a theoretical update rate of 240 Hz."

But those measurements neglect to have all axis labeled ;-) Is the 3.8ms measurement when they're in parallel from different pin-outs, or 1 long strip in series from 1 pin-out? I'm trying to run as few cables to stage as possible.

Thanks so much,

Brian

"Driving 8 LED strips simultaneously allows each strip to be only 1/8th the length. All LEDs update 8X faster than driving only a single long strip. 1000 LEDs can be updated in 3.8 ms, which allows a theoretical update rate of 240 Hz."

But those measurements neglect to have all axis labeled ;-) Is the 3.8ms measurement when they're in parallel from different pin-outs, or 1 long strip in series from 1 pin-out? I'm trying to run as few cables to stage as possible.

Thanks so much,

Brian