RichardFerraro

Well-known member

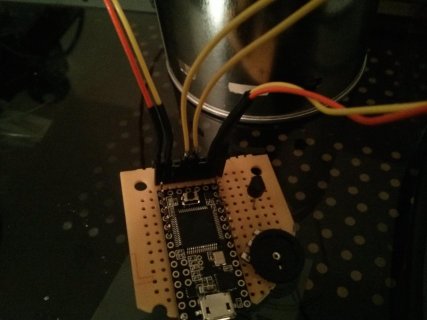

How are you folks mounting the Teensy 3/3.1 ?

I haven't figured out a good way.

Double stick tape is bad if you want to use the underside pads.

No screw holes.

Complicating the issue is during development when you need to make modifications, yet your design has to be small and void of pesky connectors.

Thanks,

Richard

I haven't figured out a good way.

Double stick tape is bad if you want to use the underside pads.

No screw holes.

Complicating the issue is during development when you need to make modifications, yet your design has to be small and void of pesky connectors.

Thanks,

Richard