Hey, I'm just gonna throw this out here.

I've got a fork of Marlin that's based on a very recent version, maybe a couple of weeks, that's "running" on a Teensy3.5.

For now it's just flashing some leds on step and dir pins but driving a stepper motor doesn't take much more than that.

I also got temperature readings working today and I've made speed lookup tables and thermistor tables to support it all.

Any feedback would be welcome. I'm just seeing how far I can go with this.

I've been pushing the changes to

here and you can compare the changes

here.

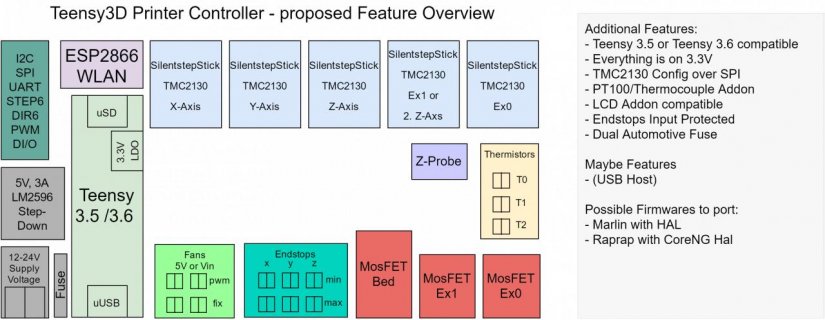

Also Paul, while I don't have any say in it, if Marlin were to implement the support into the official release, would there be any chance of some sort of adaptor board for atmega pinout to go along with RAMPS1.4? Or even an improved version of ramps with a socket for T3.5.