Because I wanted to try OSH Park and needed a breakout board for the AD8495 thermocouple amplifier, I created one and had it made.

Naked and good-looking:

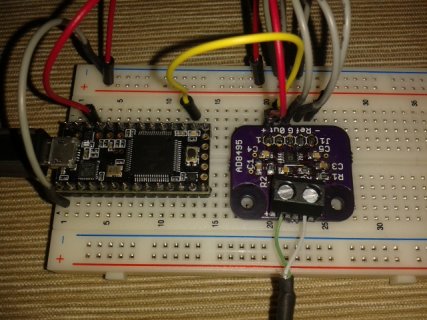

Assembled and ugly:

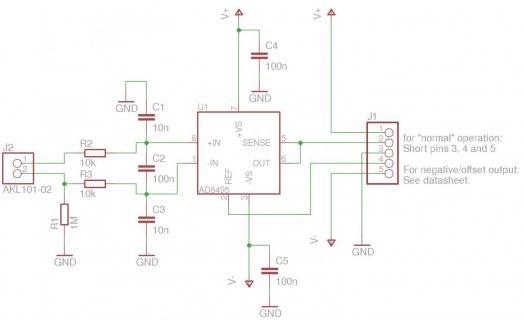

Schematic:

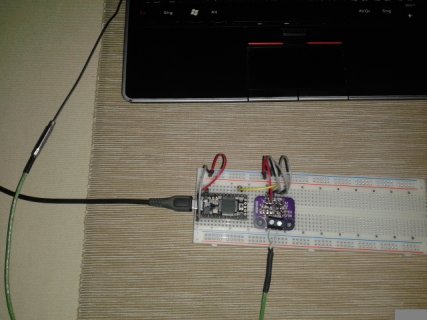

I tested it with an AD8495, type K thermocouple and a Teensy++, which worked right away.

Hackaday project page: http://hackaday.io/project/1758-AD849x-breakout-board

OSH Park: https://oshpark.com/shared_projects/QypWyps2

github: https://github.com/crteensy/AD849x-breakout-board

Regards

Christoph

Naked and good-looking:

Assembled and ugly:

Schematic:

- It is very similar to the adafruit breakout board, but supports dual supplies and a reference input for offsetting the signal.

- All caps and resistors are 0805, which is the smallest I can hand-solder without freaking out.

- Non-plated mounting holes for M2.5 screws that can be enlarged for M3, and the free area around them is large enough for an M3 washer.

I tested it with an AD8495, type K thermocouple and a Teensy++, which worked right away.

Hackaday project page: http://hackaday.io/project/1758-AD849x-breakout-board

OSH Park: https://oshpark.com/shared_projects/QypWyps2

github: https://github.com/crteensy/AD849x-breakout-board

Regards

Christoph

Last edited: