mattomatto

Well-known member

Hi all,

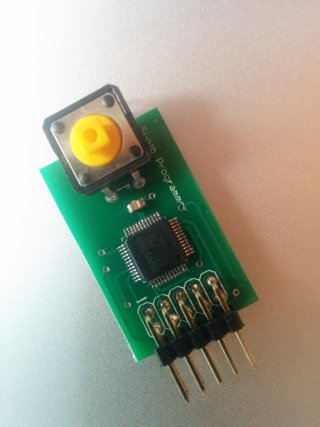

I have been developing my own board which is essentially a teensy 3.1 with the audio codec on it as well. In order to keep costs down I have also moved the Mini54, it's decoupling cap and the reset switch to a removable board to only be present when uploading.

I have just finished my first board, plugged it all in, tried to upload code and yep, nothing happens! I could now do with some help to find out why.

First of all, I am measuring power and ground as 3.3v just fine, so the regulator onboard the MK20 is working. The Mini54 also seems to be receiving power ok too. I've checked all my components with multimeter and they look to be soldered perfectly.

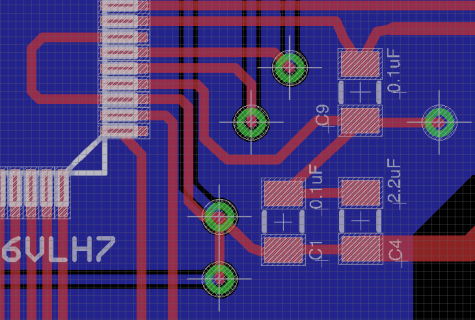

Attached is a picture of the board (The missing components are just knobs, LEDs and audio Jacks which do not need to be present), schematics and layout.

Any methods for troubleshooting, suggestions and ideas would be greatly appreciated. I guess the first question is, could there be an issues moving the Mini54 off-board like this?

This is 6 months in the making so I'm determined to get it working. Many thanks!

EDIT: This forum keeps shrinking my images so here are links to schematic/layout:

https://drive.google.com/file/d/0BwUFiZpwTq6WSXJCZmM5Q3B1ejg

https://drive.google.com/file/d/0BwUFiZpwTq6WblM3ZnNfOG40UU0

EDIT:

This is the verbose information I get when uploading:

I have been developing my own board which is essentially a teensy 3.1 with the audio codec on it as well. In order to keep costs down I have also moved the Mini54, it's decoupling cap and the reset switch to a removable board to only be present when uploading.

I have just finished my first board, plugged it all in, tried to upload code and yep, nothing happens! I could now do with some help to find out why.

First of all, I am measuring power and ground as 3.3v just fine, so the regulator onboard the MK20 is working. The Mini54 also seems to be receiving power ok too. I've checked all my components with multimeter and they look to be soldered perfectly.

Attached is a picture of the board (The missing components are just knobs, LEDs and audio Jacks which do not need to be present), schematics and layout.

Any methods for troubleshooting, suggestions and ideas would be greatly appreciated. I guess the first question is, could there be an issues moving the Mini54 off-board like this?

This is 6 months in the making so I'm determined to get it working. Many thanks!

EDIT: This forum keeps shrinking my images so here are links to schematic/layout:

https://drive.google.com/file/d/0BwUFiZpwTq6WSXJCZmM5Q3B1ejg

https://drive.google.com/file/d/0BwUFiZpwTq6WblM3ZnNfOG40UU0

EDIT:

This is the verbose information I get when uploading:

Code:

23:38:54: remote cmd: "status"

23:38:54: status data sent

23:38:54: remote cmd: "status"

23:38:54: status data sent

23:38:54: remote cmd: "status"

23:38:54: status data sent

23:38:54: remote cmd: "status"

23:38:54: status data sent

23:38:54: remote cmd: "status"

23:38:54: status data sent

23:38:54: remote cmd: "status"

23:38:54: status data sent

23:38:55: remote cmd: "status"

23:38:55: status data sent

23:38:55: remote cmd: "status"

23:38:55: status data sent

23:38:55: remote cmd: "status"

23:38:55: status data sent

23:38:55: remote cmd: "status"

23:38:55: status data sent

23:38:55: remote cmd: "status"

23:38:55: status data sent

23:38:55: remote cmd: "status"

23:38:55: status data sent

23:38:55: remote connection closed

23:39:01: Device came online, code_size = 262144

23:39:01: Board is: Teensy 3.1 (MK20DX256), version 1.03

23:39:01: File "Blink.cpp.hex". 14140 bytes, 5% used

23:39:01: File "Blink.cpp.hex". 14140 bytes, 5% used

23:39:01: elf size appears to be 262144

23:39:01: elf binary data matches hex file

23:39:01: Code size from .elf file = 262144

23:39:01: begin operation

23:39:01: flash, block=0, bs=1024, auto=1

23:39:01: flash, block=1, bs=1024, auto=1

23:39:01: flash, block=2, bs=1024, auto=1

23:39:01: flash, block=3, bs=1024, auto=1

23:39:01: HID/macos: waiting for device

23:39:01: HID/macos: waiting for device

23:39:01: flash, block=4, bs=1024, auto=1

23:39:01: flash, block=5, bs=1024, auto=1

23:39:01: flash, block=6, bs=1024, auto=1

23:39:01: HID/macos: waiting for device

23:39:01: flash, block=7, bs=1024, auto=1

23:39:01: flash, block=8, bs=1024, auto=1

23:39:01: flash, block=9, bs=1024, auto=1

23:39:01: flash, block=10, bs=1024, auto=1

23:39:01: flash, block=11, bs=1024, auto=1

23:39:01: flash, block=12, bs=1024, auto=1

23:39:01: flash, block=13, bs=1024, auto=1

23:39:01: sending reboot

23:39:01: begin wait_until_offline

23:39:01: HID/macos: status: ok

23:39:02: offline, waited 3

23:39:02: end operation

23:39:02: redraw timer set, image 14 to show for 1200 ms

23:39:02: HID/macos: number of devices found = 0

23:39:02: HID/macos: no devices found (empty set)

23:39:03: redraw, image 9

Last edited: