neep

Well-known member

Hi all,

after a break I'm about to embark on a new LED toy project this winter. I'd like to go for a much higher resolution this time, after having worked with W2801 a few years back on some spin props. I see great strides have been made in addressing the WS2811/2812 strips using Teensy using the OctoWS2811 library. The density of these strips can go up to a pretty amazing 144 LEDs/m from what I can find on Aliexpress these days. However I'm looking for an even higher density, as I came across these:

http://lighttoys.cz/store/led-products/visual-poi-staff/

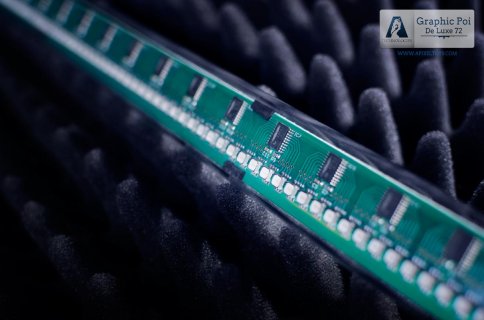

These have 80 LEDs packed next to each other within about 45cm of length. So translated to 1m that should come at about 178 LEDs/m. Has anyone seen off-the-shelf strips being sold like this? Also, they say that these LEDs are "360 degrees" and "custom made". Does anyone know what chip is used in this toy? It could also be that they had the PCBs custom made completely, of course.

after a break I'm about to embark on a new LED toy project this winter. I'd like to go for a much higher resolution this time, after having worked with W2801 a few years back on some spin props. I see great strides have been made in addressing the WS2811/2812 strips using Teensy using the OctoWS2811 library. The density of these strips can go up to a pretty amazing 144 LEDs/m from what I can find on Aliexpress these days. However I'm looking for an even higher density, as I came across these:

http://lighttoys.cz/store/led-products/visual-poi-staff/

These have 80 LEDs packed next to each other within about 45cm of length. So translated to 1m that should come at about 178 LEDs/m. Has anyone seen off-the-shelf strips being sold like this? Also, they say that these LEDs are "360 degrees" and "custom made". Does anyone know what chip is used in this toy? It could also be that they had the PCBs custom made completely, of course.

Last edited: