Constantin

Well-known member

Hi guys,

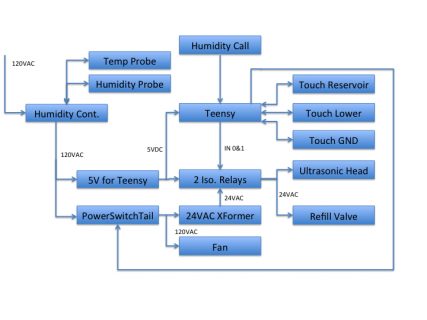

Some news from my latest project, a whole-house humidifier controlled by a Teensy 3. I got sick of the humidifier my contractor installed because the bottle that the steam is made in has to be replaced annually and the electric bills reach such happy heights that the electric company keeps insisting on sending us fruit platters as a thank you.

My first foray into this was creating a clean water supply, so now we have a very small RO system, which works great. I then installed a Trion CB707 atomizer, which was a bit underwhelming. Not only was the thing loud, it did a great job of slinging lots of water into the ductwork, such that after about 1/2 hour of operation, the ducts had 2x3' puddles in them. While galvanized steel is somewhat water resistant, the ductwork wasn't going to survive that abuse forever.

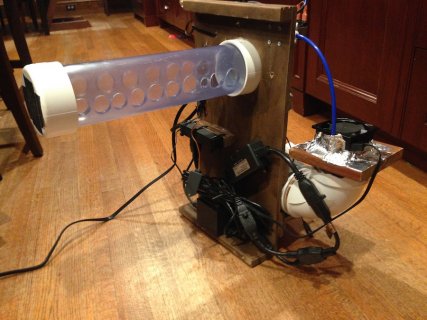

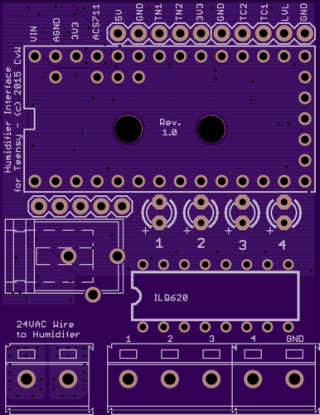

So, I put on my thinking cap and came up with a ultra-sonic based humidifier that is mounted inside some PVC pieces. These humidifiers are neat in that they include a sensor to prevent them from running whenever the water level is too low. To prevent overflows, I have an oversized drain also. But how to sense water levels? I tried the CAP1188 from Adafruit but quickly realized that it was way too difficult for me to use with a water level sensing application. Teensy to the rescue!

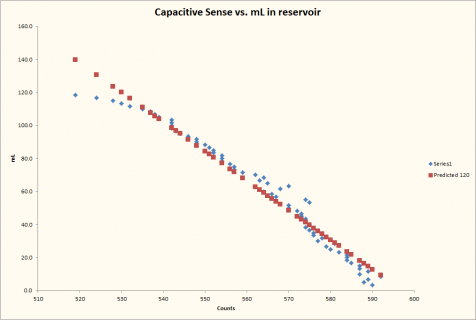

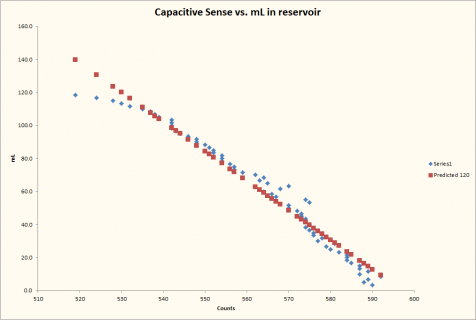

So, I hooked up a Teensy 3 to a number copper strips that I had glued to the outside of the reservoir that the ultrasonic emitter sits on. Based on a regression analysis, I estimate my standard error is on the order of 6mL, which is close enough for me to maintain the water levels inside the reservoir to within 60mL and keep the humidifier happy. So the next step is to verify performance, hook up all the wires, and then install...

Nifty... I wonder if it will drift and all that!

Some news from my latest project, a whole-house humidifier controlled by a Teensy 3. I got sick of the humidifier my contractor installed because the bottle that the steam is made in has to be replaced annually and the electric bills reach such happy heights that the electric company keeps insisting on sending us fruit platters as a thank you.

My first foray into this was creating a clean water supply, so now we have a very small RO system, which works great. I then installed a Trion CB707 atomizer, which was a bit underwhelming. Not only was the thing loud, it did a great job of slinging lots of water into the ductwork, such that after about 1/2 hour of operation, the ducts had 2x3' puddles in them. While galvanized steel is somewhat water resistant, the ductwork wasn't going to survive that abuse forever.

So, I put on my thinking cap and came up with a ultra-sonic based humidifier that is mounted inside some PVC pieces. These humidifiers are neat in that they include a sensor to prevent them from running whenever the water level is too low. To prevent overflows, I have an oversized drain also. But how to sense water levels? I tried the CAP1188 from Adafruit but quickly realized that it was way too difficult for me to use with a water level sensing application. Teensy to the rescue!

So, I hooked up a Teensy 3 to a number copper strips that I had glued to the outside of the reservoir that the ultrasonic emitter sits on. Based on a regression analysis, I estimate my standard error is on the order of 6mL, which is close enough for me to maintain the water levels inside the reservoir to within 60mL and keep the humidifier happy. So the next step is to verify performance, hook up all the wires, and then install...

Nifty... I wonder if it will drift and all that!

Last edited: