Automotive transients get to about 50 V for a duration of about 100 ms. You should size your zener and the 1st resistor for that.

1: Small zeners can handle about 400 mW continuously, about 1 W for this small duration -- at 25 V, that's 40 mA. With 50 V at the input and 25 V on the zener, that's (50-25)/R = 40 mA ==> R = 625 ohms -- so use 1 kohm. With 1 kohm, zener leakage (few uA) will have a negligible effect.

2: Now you want to divide the input so 25 V generates 3.3 V. That's a ratio of 3.3/25 = 0.132 -- let's use 1/8 for simplicity.

3: Remember you still have 1 k in the input path (and the zener has no effect for 'normal' voltages). To divide by 8, you need 7*R on the top and 1*R on the bottom, but the 7*R should include the value of the 1 k. A good starting point for the lower R is 1 k. This means the upper one is 7 k total, or 6 k allowing for the first 1k. You can't (easily) get 6 k resistors, but 2 12 k's in parallel will work.

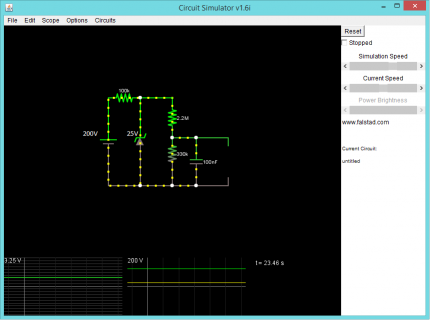

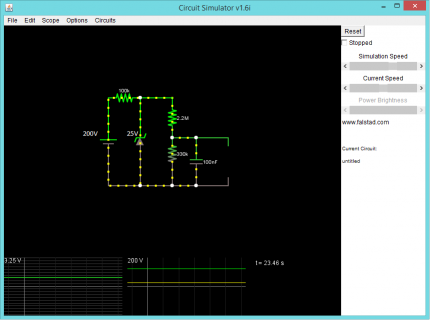

So, now you have: 1 k from the battery to the zener; the zener to ground, 12k//12k from the zener to the ADC input, and 1k from that node to GND. Add a 100 nF also, and you have a reasonable circuit.

Check power dissipation:

At 50 V, the current is 25 mA (from (50-25)V/1k); so the power is I^2*R = 0.025^2*1000 = 0.62 W. This is only for a transient, the static power would be (assume 16 V max. if you have a bad battery; 26 V if you get jump starts from 24 V trucks !) across 1k+6k+1k, or 8k. This power is V^2/R = 16^2/8k = 32 mW -- no problem for the components.

Accuracy -- Resistors may be about 2 % tolerance -- so this will limit your circuit's accuracy. They will be reasonably stable, so you could calibrate and include the cal in your software. A larger error may be how you connect to the voltage you want to measure -- 'Ground' is not easily defined in an automotive system, and vehicle chassis may be 100's of mV different from the battery -ve terminal due do battery and lighting currents (as well as starter currents etc.).