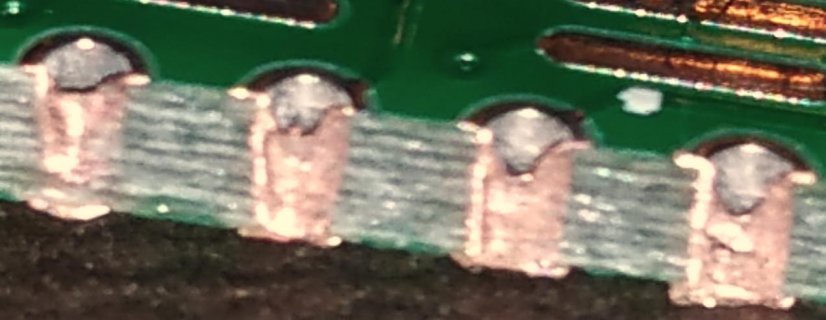

I'd wager an ice cream sandwich that if you come up with a pad representation of the Teensy underside (i.e. a round pad for every hole, a rectangular pad for every underside pad, etc.) that you could reflow the teensy right onto a new board, no cutting required. In fact, you may even get good connections to the Pogo-pin receptacles like D+, D-, reset, etc.

I'd wager a further ice cream sandwich that a hot plate approach with a good stainless stencil for the paste is more than good enough to get the job done, as long as you align the teensy well each time (maybe use header pins in opposite corners to fix the thing in place, then snip off the excess when done).

The reason I'd look into the hot plate vs. using an oven is to lessen the stress of the components on top. I.e. cook the PCB below vs. cooking the Teensy components up top. Or in a reflow oven, you could simply disconnect the top emitters and only heat from below. At some point in the future, I'll do just that, i.e. use that dual SCR I have in mine to selectively turn on and turn off heaters above and below. The idea being that the quartz lamps below are great for initial baseline and soak while the top quartz come on for the quick rise to reflow temperatures.