joe_prince

Well-known member

I just finished designing a breakout board for the BNO055 chip (first PCB I've designed so it's more for practice than anything). I had a few questions that hopefully some will be able to address. Here are the board, schematic, and GERBER files for reference: View attachment BNO055_breakout_board.zip

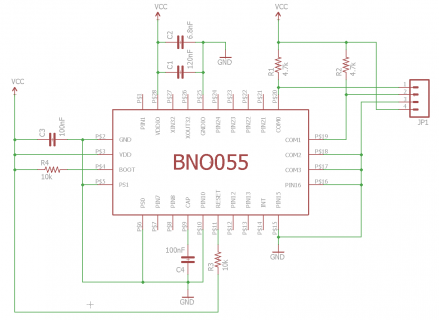

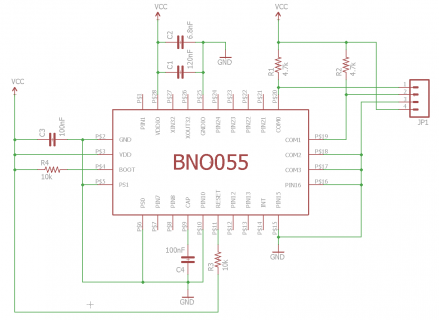

Schematic:

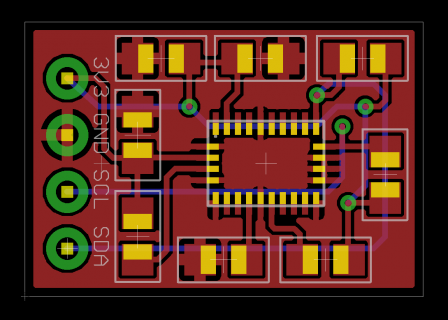

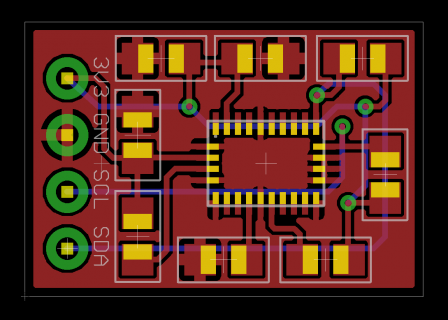

Board:

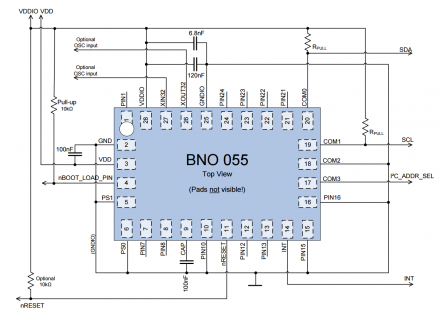

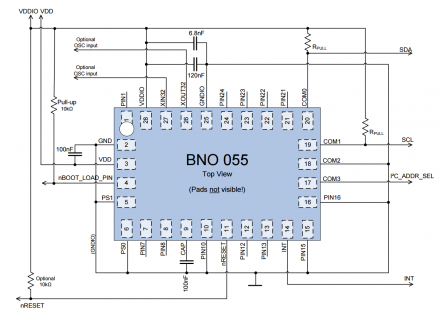

BNO055 Schematic:

1) For the capacitors and resistors I'm using 0805 SMDs. I have some of the exact values that I need, but for some I do not and Digi-Key and Mouser only have them in reels of 3000 for the values I need. So for the 4.7k resistors, the closest I have is 4.3k and 5.1k. For the 6.8nF capacitor, the closest I have is 1nF and 10nF. And for the 120nF, the closest I have is 100nF. Can any of these be used instead of the actual values or do I have to find another way to get the exact value for them? For the 4.7k pull-ups, I imagine it's fine to use a close value, but for the capacitors I'm unsure.

2) I'm going to use OSH Park to have the boards fabricated, but I was also looking to get a stencil done since it would be hard to apply the solder paste by hand for the LGA BNO055. I found OSH Stencils (https://www.oshstencils.com/) by searching, which I don't believe has any affiliation with OSH Park, and was wondering if anyone has used them. If not, do you have any recommendations?

3) Is there anything about the board design in general that I should watch out for? Any issues with my board that I should fix before sending off the files?

Thanks in advance for all the help! I just download EAGLE CAD last week, and have been watching tons of videos and reading books on it so I still have a lot to learn.

Schematic:

Board:

BNO055 Schematic:

1) For the capacitors and resistors I'm using 0805 SMDs. I have some of the exact values that I need, but for some I do not and Digi-Key and Mouser only have them in reels of 3000 for the values I need. So for the 4.7k resistors, the closest I have is 4.3k and 5.1k. For the 6.8nF capacitor, the closest I have is 1nF and 10nF. And for the 120nF, the closest I have is 100nF. Can any of these be used instead of the actual values or do I have to find another way to get the exact value for them? For the 4.7k pull-ups, I imagine it's fine to use a close value, but for the capacitors I'm unsure.

2) I'm going to use OSH Park to have the boards fabricated, but I was also looking to get a stencil done since it would be hard to apply the solder paste by hand for the LGA BNO055. I found OSH Stencils (https://www.oshstencils.com/) by searching, which I don't believe has any affiliation with OSH Park, and was wondering if anyone has used them. If not, do you have any recommendations?

3) Is there anything about the board design in general that I should watch out for? Any issues with my board that I should fix before sending off the files?

Thanks in advance for all the help! I just download EAGLE CAD last week, and have been watching tons of videos and reading books on it so I still have a lot to learn.