Hey Everyone!

I have my first teensy on the way (3.2) and I was hoping to get a little bit of advice.

I am planning to use the Teensy to control two 12V Hydraulic solenoids. Bottom of page 35 in manual for PVEH.

http://files.danfoss.com/documents/pve%20series%204%20electrical%20actuating%20module%20for%20pvg%2032%20100%20120%20and%20pvhc%20technical%20information%20manual/520l0553.pdf

I have a regulated 12V source available.

The solenoids are at 0 at 0.5 * SupplyV

A-port ↔ B-port 0.25 → 75 * SupplyV

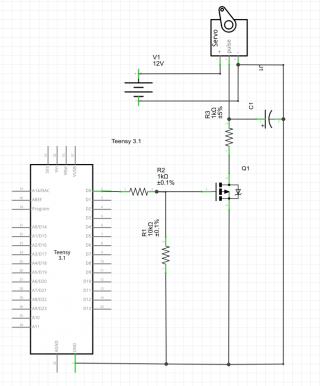

My thoughts were:

PWM outputs set to 187500Hz

Two logic level N MOSFETs on two Teensy pins

RC filter after each MOSFET with R=1K and C=100nF

This will give me a settling time of 0.00023 seconds and a ripple of 0.159v (~1%).

Does this sound like a good approach?

Thanks,

Sam

I have my first teensy on the way (3.2) and I was hoping to get a little bit of advice.

I am planning to use the Teensy to control two 12V Hydraulic solenoids. Bottom of page 35 in manual for PVEH.

http://files.danfoss.com/documents/pve%20series%204%20electrical%20actuating%20module%20for%20pvg%2032%20100%20120%20and%20pvhc%20technical%20information%20manual/520l0553.pdf

I have a regulated 12V source available.

The solenoids are at 0 at 0.5 * SupplyV

A-port ↔ B-port 0.25 → 75 * SupplyV

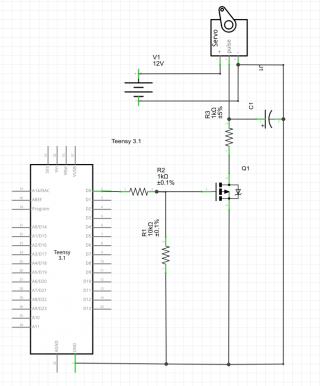

My thoughts were:

PWM outputs set to 187500Hz

Two logic level N MOSFETs on two Teensy pins

RC filter after each MOSFET with R=1K and C=100nF

This will give me a settling time of 0.00023 seconds and a ripple of 0.159v (~1%).

Does this sound like a good approach?

Thanks,

Sam

Last edited: