bicycleguy

Well-known member

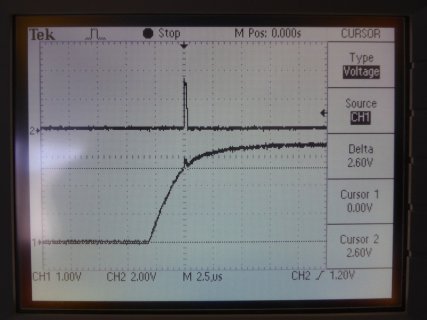

I have a motor encoder using a single magnet stuck axially on the end of a motor shaft with two properly located MLX92211 hall sensors reading the magfield change to make a very clean debounced quadrature signal. The Arduino mega version of my controller never looses the motor position. The Teensy looses it in a quisi random way, quisi because I don't know why  Sometimes works for minutes without an error, sometimes hours.

Sometimes works for minutes without an error, sometimes hours.

Because of the hardware required to test, I'm not sure posting the code is going to help much.

I have the interrupt related code here:

With this code if I spin the motor the encoder will print out. Of course I haven't been able to make this fail even spinning with a drill.

even spinning with a drill.

The complete code does stuff on every pin, here's some of the functions:

Would using pwm, 2 serials, 4 other interrupts and I2C at the same time cause issues with my count?

Because of the hardware required to test, I'm not sure posting the code is going to help much.

I have the interrupt related code here:

Code:

#define MYVERSION_STUFF "EncoderTeensy 6/14/2016"

//Names for i/o pins used:

//Interrupt inputs for motors, speed and cadence switches

const int NCDR_R1 = 17; //rear Hall MLX92211 requires mag field reversal to switch

const int NCDR_R2 = 16; //rear "

//hallswitch motor encoder stuff

volatile int vrencodercnt = 0;

void setup() {

pinMode(NCDR_R1, INPUT_PULLUP); //pull up the interrupt pin. Hall sensor rear motor

pinMode(NCDR_R2, INPUT_PULLUP); //pull up the interrupt pin. Hall sensor rear motor

attachInterrupt(digitalPinToInterrupt(NCDR_R1), ncdr_R1Int, CHANGE);

attachInterrupt(digitalPinToInterrupt(NCDR_R2), ncdr_R2Int, CHANGE);

Serial.begin(9600);

delay(1000);

Serial.println(MYVERSION_STUFF); //CHANGELOG

}

void loop() {

static int lastcount=-999;

int thecount=rCount();

if(thecount!=lastcount){ //only print on change

lastcount=thecount;

Serial.println(lastcount);

}

}

void ncdr_R1Int(){

vrencodercnt+=digitalRead(NCDR_R1)==digitalRead(NCDR_R2) ? -1 : 1;

}

void ncdr_R2Int(){

vrencodercnt+=digitalRead(NCDR_R1)==digitalRead(NCDR_R2) ? 1 : -1;

}

int rCount(){

int r;

// disable interrupts while we read volatile

noInterrupts();

r=vrencodercnt;

interrupts();

return r;

}With this code if I spin the motor the encoder will print out. Of course I haven't been able to make this fail

The complete code does stuff on every pin, here's some of the functions:

Code:

//Names for i/o pins used:

const int GREENBUTTON= 22; // Digital input for button to go down, uses internal pull-up, also outputs for led

const int YELLOWBUTTON = 21; // Digital input for button to go up, uses internal pull-up, also outputs for led

const int STOPBUTTON = 20; // Digital input for button to go stop, uses internal pull-up, also outputs for led

const int BUTTON1 = 2;

const int BUTTON5 = 23;

const int MYSCL = 19; // SCL for TWI/I2C

const int MYSDA = 18; // SDA for TWI/I2C

//Interrupt inputs for motors, speed and cadence switches

const int NCDR_R1 = 17; //rear Hall MLX92211 requires mag field reversal to switch and is twice as sensitve

const int NCDR_R2 = 16; //rear "

const int NCDR_F1 = 12; //front "

const int NCDR_F2 = 5; //front "

const int SPEEDPN = 15; //reed switch N.O. switched to gnd calls speedInt()

const int CADENCEPIN = 14; //Hall MLX92212 rqrs a south pole .3 inch. N pole no effect. calls cadenceInt

//motor control outputs

const int OUT1=11; //phase 1,rear motor

const int OUT2=8; //phase 2,rear motor

const int PWM_R=4; //PWM output, enable rear motor

const int PWM_F=3; //PWM output, enable front motor

const int OUT3=6; //phase 1,front motor

const int OUT4=7; //phase 2,front motor

const int LCDdisplay=1; //TX1 for Serial1 LCD display

const int RASPBERRYTX = 9; //for logging to pi

const int RASPBERRYRX = 10;

const int AVAILABLEPIN = 13; // on board ledWould using pwm, 2 serials, 4 other interrupts and I2C at the same time cause issues with my count?