Hi Everyone,

I have been working on a project and getting some odd behaviours when using an optical slotted switch (http://www.digikey.ca/product-detail/en/tt-electronics-optek-technology/OPB625/365-1090-ND/498727)

It is set up on a indoor bicycle that is reading a custom chainring that has 72 teeth, and is used to measure both the angle of the pedal, but also the angular velocity. I have always had it set up to read when a tooth blocks the sensor, or when there is a falling edge in the signal. It worked during all my breadboard testing, however as soon as I started to use a teensy 3.2 (5v tolerant digital) vs a 3.1 (used a logic level converter 5-3.3v), I am getting a reading of 2us.

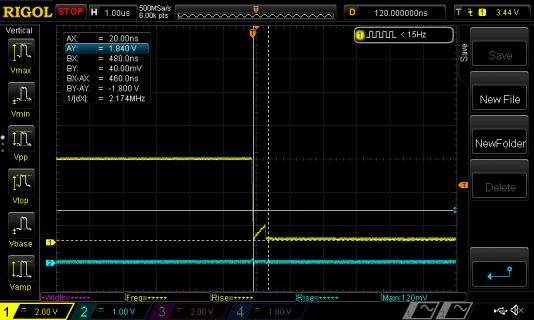

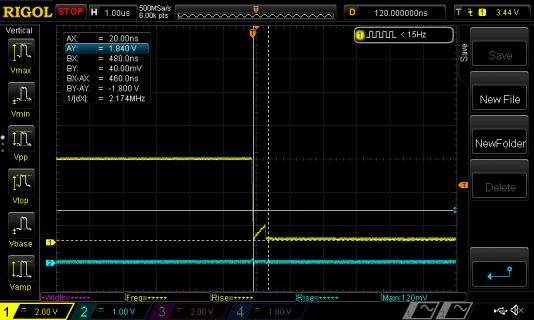

At first the only thing I could think of was to put a capacitor on the digital output signal, which worked (also as soon as I hooked up the OScope the device works, unhook it and get wrong reading). Even though it worked I was still in the dark as to why I was having this issue. So I hooked up the scope again and got this image which shows the digital signal bounces up to a level that must activate the interrupt (This image is with cap in place, without it bounces to 1.2V). This is the code in my interrupt routine which I thought would eliminate any bad readings by setting a limit of 3000us, however does not seem to be the case. See code below. Even though it working, I still don't know exactly why and that is driving me crazy, plus I like things to be perfect. Thanks for your time and any experts out there that might have an idea, I would love to hear it. Forgot to mention the optical switch has a 10k pull up resistor built in, so in theory when I add a capacitor it creates an RC filter (30pf is the lowest capacitor that works, but 0.1uf also works, but creates a very slow rise time in the signal)

which shows the digital signal bounces up to a level that must activate the interrupt (This image is with cap in place, without it bounces to 1.2V). This is the code in my interrupt routine which I thought would eliminate any bad readings by setting a limit of 3000us, however does not seem to be the case. See code below. Even though it working, I still don't know exactly why and that is driving me crazy, plus I like things to be perfect. Thanks for your time and any experts out there that might have an idea, I would love to hear it. Forgot to mention the optical switch has a 10k pull up resistor built in, so in theory when I add a capacitor it creates an RC filter (30pf is the lowest capacitor that works, but 0.1uf also works, but creates a very slow rise time in the signal)

I have been working on a project and getting some odd behaviours when using an optical slotted switch (http://www.digikey.ca/product-detail/en/tt-electronics-optek-technology/OPB625/365-1090-ND/498727)

It is set up on a indoor bicycle that is reading a custom chainring that has 72 teeth, and is used to measure both the angle of the pedal, but also the angular velocity. I have always had it set up to read when a tooth blocks the sensor, or when there is a falling edge in the signal. It worked during all my breadboard testing, however as soon as I started to use a teensy 3.2 (5v tolerant digital) vs a 3.1 (used a logic level converter 5-3.3v), I am getting a reading of 2us.

At first the only thing I could think of was to put a capacitor on the digital output signal, which worked (also as soon as I hooked up the OScope the device works, unhook it and get wrong reading). Even though it worked I was still in the dark as to why I was having this issue. So I hooked up the scope again and got this image

which shows the digital signal bounces up to a level that must activate the interrupt (This image is with cap in place, without it bounces to 1.2V). This is the code in my interrupt routine which I thought would eliminate any bad readings by setting a limit of 3000us, however does not seem to be the case. See code below. Even though it working, I still don't know exactly why and that is driving me crazy, plus I like things to be perfect. Thanks for your time and any experts out there that might have an idea, I would love to hear it. Forgot to mention the optical switch has a 10k pull up resistor built in, so in theory when I add a capacitor it creates an RC filter (30pf is the lowest capacitor that works, but 0.1uf also works, but creates a very slow rise time in the signal)

which shows the digital signal bounces up to a level that must activate the interrupt (This image is with cap in place, without it bounces to 1.2V). This is the code in my interrupt routine which I thought would eliminate any bad readings by setting a limit of 3000us, however does not seem to be the case. See code below. Even though it working, I still don't know exactly why and that is driving me crazy, plus I like things to be perfect. Thanks for your time and any experts out there that might have an idea, I would love to hear it. Forgot to mention the optical switch has a 10k pull up resistor built in, so in theory when I add a capacitor it creates an RC filter (30pf is the lowest capacitor that works, but 0.1uf also works, but creates a very slow rise time in the signal)

Code:

//June 2016

//Track Cycling SRM Platinum collection program

//Updated from BMX sketch, adjust buffersize to get all samples during slower start

//OSH Board Ver 1

//No Direction pin used

#define hzPin 11 //PortC

#define degPin 0 //PortB

#define cadencePin 2 //PortD

#define dirPin 4 //PortA, not used, but will still set as input

#define DEGREE_FLAG 1

#define Cadence_FLAG 2

#define calLED 7

#define calLED2 15

#define LIGHTS true //If you want a signal light at specific angle

//TDC=360 deg

uint16_t degOn = 360;//start of indicator light

uint16_t degOff = 5;//stop of indicator light

// rising edge indicates 360 or tdc, used in labview post processing

#define PulsePin 22 //

#define PULSEOUT true //if need a position pulse, set to true

uint16_t PulseLow = 180;

uint16_t PulseHigh = 360;

volatile uint8_t bUpdateFlagsShared; //hold the updated flag

// shared variables are updated by the ISR and read by loop.

//Evan June Pilot testing max 629 samples at 9259hz

//Will be bike dependent if slope is larger or smaller

const int BUFFERSIZE=1000; //Adjust to meet needs of Track Cycling, adjust labview accordingly

volatile int DegreeTimeShared;

volatile int CadenceTimeShared;

volatile uint16_t HZSamplesShared = 0;

volatile int HZInShared[BUFFERSIZE];

volatile int IndexShared;

volatile int PositionShared;

volatile int PositionDegShared;

volatile unsigned long DegreeStart;

unsigned long HZStart;

unsigned long HZPeriod;

unsigned long HZ;

unsigned long CadenceStart;

float Offset = 460.00; //Van SRM 474, Victoria 533: typical offset value

float sum = 0.00;

uint8_t offsetcount = 0;

uint16_t i=0;

uint16_t count=0;

boolean calibrate = false;

int SampleSize;

uint8_t collectionCount = 2;

void setup(void)

{

Serial.begin(115200);

pinMode(hzPin, INPUT); //pin 11

pinMode(degPin, INPUT); //pin 0

pinMode(cadencePin, INPUT); //pin 2

pinMode(dirPin, INPUT); //pin 4, just to protect teensy, not used

pinMode(calLED, OUTPUT); //Calibrate LED

pinMode(calLED2, OUTPUT);

pinMode(PulsePin, OUTPUT);

NVIC_SET_PRIORITY(IRQ_PORTC,32); //Pin 11 is on Port C 0=Highest

//if using 3.3V, then RISING works better, if 5V switch to FALLING

//however, both seem to work for 3.3V

attachInterrupt(hzPin, counterhz, RISING);//schmitt trigger inverts signal

//collect 2000 samples to determine offset

collectionCount = 2000 / BUFFERSIZE;

while (calibrate == true) {

digitalWrite(calLED, HIGH);

digitalWrite(calLED2, HIGH);

}

//delay(5000);

digitalWrite(calLED, LOW); //turn off calibrate light

digitalWrite(calLED2, LOW);

SampleSize = BUFFERSIZE*collectionCount;

SampleSize = SampleSize-10;

Offset = sum/SampleSize; //Calculate average of samples collected

//Serial.println(SampleSize);

//Serial.println(Offset);

//did not work with encoder without Oscope connected to ground, try with capacitors

//changed degPin to RISING since falling did not work, however dbl counted position

//need to try another method with capacitors, maybe less than 100nf

//creating RC time constant with 10k pullup, try 100pf (0.0108ms delay)

//added 30pf and fixed the timing issue

//sensor seems to bounce when falling edge, so might have to use rising with capacitor

//30pf reduces bounce to 940mv which won't trigger interupt

attachInterrupt(degPin, counterDeg, FALLING); //Start at leading edge of Tooth

attachInterrupt(cadencePin, doIndex, RISING);//Starts at index opening

}

void loop(void)

{

static int DegreeTime;

static int HZIn[BUFFERSIZE];

static int Index;

static int Position;

static int PositionDeg;

static uint8_t bUpdateFlags;

static uint16_t HZSamples = 0;

if (Serial.available() > 0) {

int inByte = Serial.read();

switch (inByte) {

case 'a':

IndexShared = 0; //if serial is a, reset index

Serial.flush();

break;

case 'c': //Calibrate SRM Offset

calibrate = true;

offsetcount=0;

sum = 0;

while (calibrate == true){

digitalWriteFast(calLED,HIGH);

digitalWriteFast(calLED2,HIGH);

}

Offset = sum/SampleSize;

digitalWriteFast(calLED,LOW);

digitalWriteFast(calLED2,LOW);

//Serial.println(sum);

//Serial.println(Offset);

Serial.flush();

break;

}

}

if(bUpdateFlagsShared)

{

noInterrupts(); // turn interrupts off quickly while we take local copies of the shared variables

// take a local copy of which channels were updated in case we need to use this in the rest of loop

bUpdateFlags = bUpdateFlagsShared;

if(bUpdateFlags & DEGREE_FLAG)

{

DegreeTime = DegreeTimeShared;

HZSamples = HZSamplesShared;

Index = IndexShared;

Position = PositionShared;

PositionDeg = PositionDegShared;

for (int k=0; k<HZSamples; k++)

{

HZIn [k] = HZInShared [k]; //copy HZ array

}

}

bUpdateFlagsShared = 0;

HZSamplesShared=0;

interrupts(); //turn back on

}

if(bUpdateFlags & DEGREE_FLAG ){

Serial.print ("O");

Serial.print (Offset);

Serial.print ("I");

Serial.print (Index);

Serial.print ("D");

Serial.print (DegreeTime);

Serial.print ("C");

Serial.print (CadenceTimeShared);

Serial.print ("P");

Serial.print (Position);

Serial.print ("Q");

Serial.print (PositionDeg);

Serial.print ("H");

for ( i=0; i<HZSamples; i++) { //print HZ array

Serial.print(HZIn[i]);

if (i<HZSamples-1){

Serial.print(",");

}

}

Serial.println();

Serial.send_now();

bUpdateFlags = 0;

}

//If set to true, light will flash at positions set above

if (LIGHTS) {

if (PositionDeg == degOn) {

digitalWriteFast(calLED, HIGH); //Flash LED to use in Video Sync?

digitalWriteFast(calLED2, HIGH);

}

if (PositionDeg == degOff || PositionDeg > 360) { //if above 360 turn off

digitalWriteFast(calLED, LOW); //

digitalWriteFast(calLED2, LOW);

}

}

//Send digital pulse out when needed to send sync to other device

if (PULSEOUT) {

if (PositionDeg == PulseHigh)digitalWriteFast(PulsePin, HIGH); //attach to ADC to sync EMG when Right TDC

if (PositionDeg == PulseLow || PositionDeg > 360) digitalWriteFast(PulsePin, LOW); //reset if above 360

}

}

//Triggers on RISING (index open = HIGH)

//Adjust gap so rising just after 360 trigger (falling edge)

void doIndex() { //Cadence

if (PositionShared >= 71){ //to prevent false reset on bad index signal, OMIT?

PositionShared=-1; //Reset position to -1 since want position 0-71

PositionDegShared=0; //Reset degree position want 5-360deg

CadenceTimeShared=millis()-CadenceStart;

CadenceStart=millis();

IndexShared++;

}

}

//Trigger on Falling, or leading edge of tooth

void counterDeg()// Degree Time

{

DegreeTimeShared=micros()-DegreeStart;

if (DegreeTimeShared >= 3000){ //to prevent false firing, 3000 = 278rpm

DegreeStart=micros();

PositionShared++;

PositionDegShared+=5;

bUpdateFlagsShared |= DEGREE_FLAG;

}

}

FASTRUN void counterhz() //Frequency

{

HZPeriod = micros() - HZStart;

if (HZPeriod >= 75){ //285us=3500hz, 334=3000hz, 75=13333hz

HZStart=micros();

HZ=1000000 / HZPeriod; //convert period to frequency

if ( HZSamplesShared < BUFFERSIZE && HZ >300 && HZ < 10000) { //fill array with all HZ per chaing ring tooth

//Vic SRM offset ~530hz

//Van SRM offset ~400hz

//Vic Test rig ~390

HZInShared[HZSamplesShared++] = HZ;

HZ=10000; //changed from 8500

}

}

//Below is only called during collect offset

if(HZSamplesShared == BUFFERSIZE && calibrate == true){ //Changed single & to &&, so make sure it works

for (int b=2; b<BUFFERSIZE; b++)//ignore first couple samples, for some reason get spikes

{

sum += HZInShared [b]; //Sum samples

}

offsetcount++;

HZSamplesShared=0;

}

if (offsetcount == collectionCount) calibrate = false; //stop calibration, size dependent on BUFFERSIZE

}