KurtE

Senior Member+

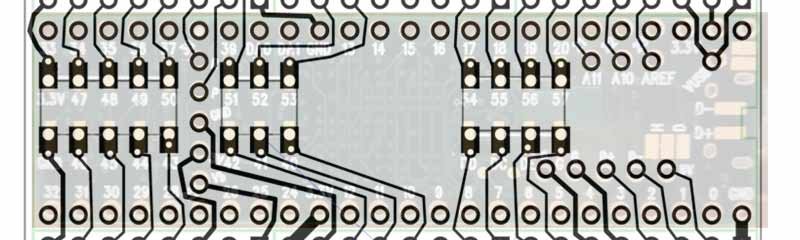

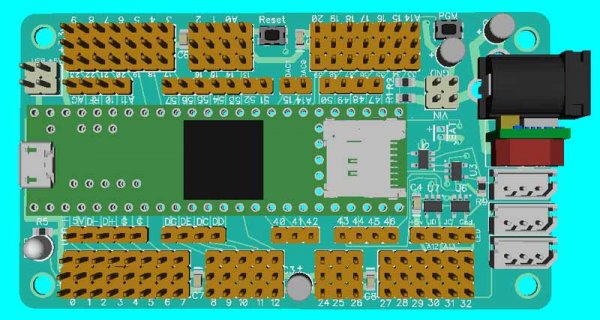

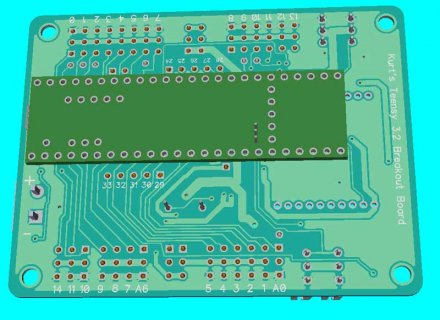

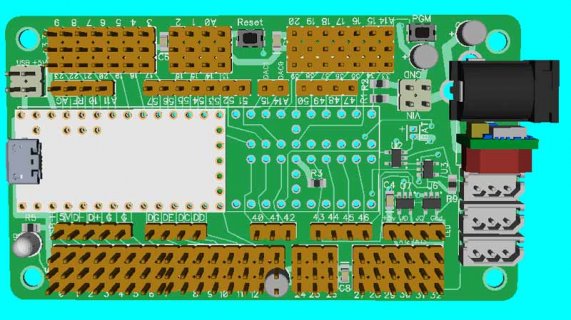

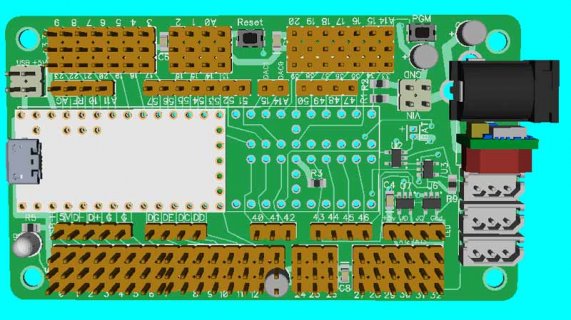

As I mentioned in the K66 Beta thread #1128 and some of the other posts, I decided I wanted to make a quick and dirty breakout board that had some of the features I normally use, like 3 pin headers and the like.

Michael had a lot of good suggestions in the following posting:

I hacked around some more on it to address some of the issues mentioned, plus add a few things, but so far tried to avoid adding the kitchen sink.

I added more room behind the back end of the board to hopefully allow insertions and removals of SD card.

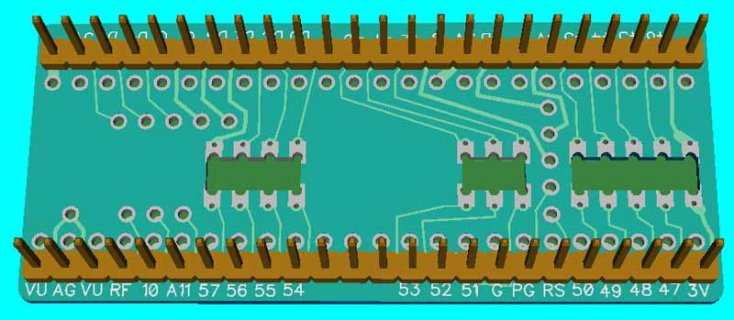

I did not yet widen the board to allow me to choose additional power capabilities, like choose what voltage goes to the pins. Nor did I extend on the capbilities for ARef and AGnd. Note: those pins are brought out and labeled AG and RF.

I played around some with adding the JST connector and allow run from 1 lipo and maybe add charging circuit, but punted for now as I would not have +5v, not sure how best to power things, like probably separate powering of Teensy from other stuff. I did add a 2x2 connector with GND and VIN, so you can use those to jumper in or out of the board. My thinking is if you need this, the board should still be compatible with the stuff up on Tindie...

Added PGM button.

Added .127 2 pin connector area going to VBAT/GND to allow RTC battery backup. Not sure what part to use there, but this appears to be the size of connector of some of these batteries. Example ones from ODRoid.

One Kitchen Sink: I like LEDs, like Neopixels, So added on Two level converters (and gates like prop shield). Also used IO pins associated with SPI2 CLK/MOSI, so can use dotstar as well (I believe).

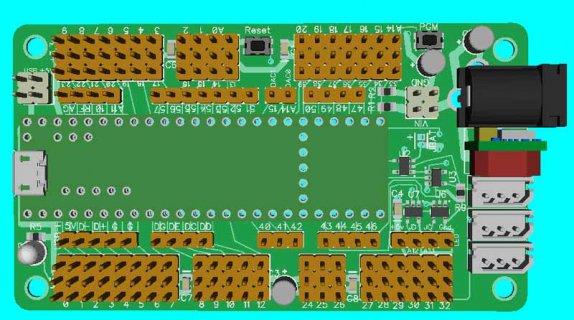

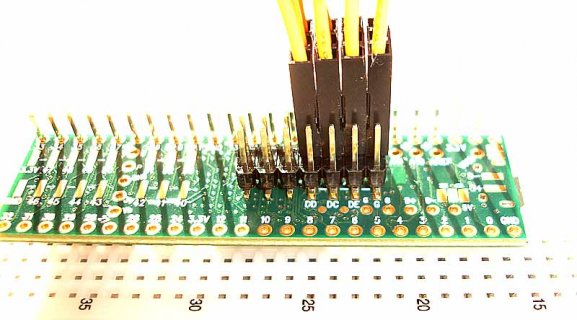

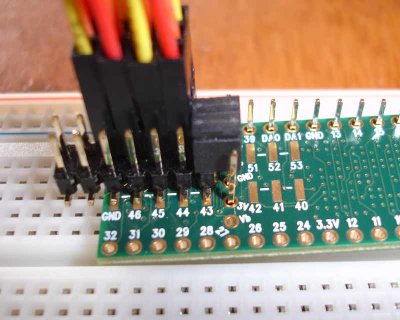

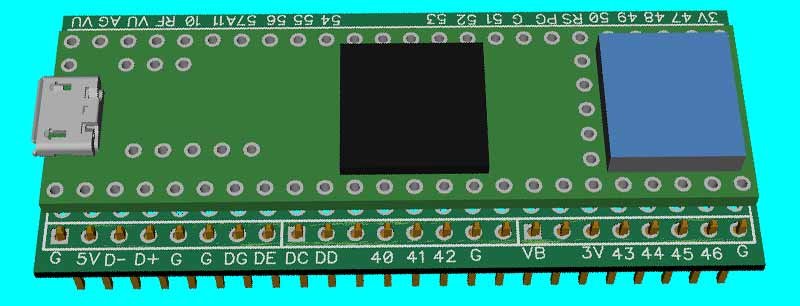

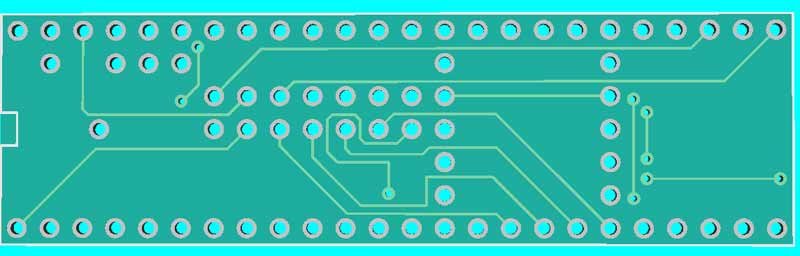

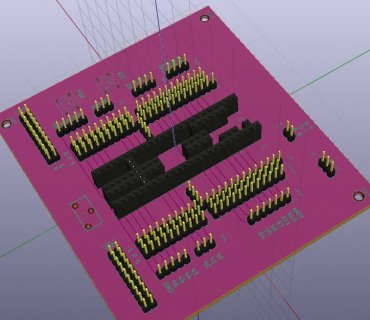

Board currently looks something like:

There are more things I would like Sound... But not sure of best approach now, also would need to increase size of board to add speaker, so decided to wait on this to see what options we might have. So I ordered a set of 4 of these from Digistump, for about $24.

Now back to playing with the hardware and software.

Michael had a lot of good suggestions in the following posting:

Code:

KurtE: A couple of thoughts, feel free to ignore them:

You might not want to put something behind the back of the Teensy 3.6/3.5 to allow the user to easily insert/remove micro sd cards;

I found in putting headers on my 3.6 that the program key is hard to get to. It might be useful to break out the program pin just like you did with the reset pin;

I don't know if it would be useful to change the 3x header rows to 4x. On the data pin side, it would be useful to bring out VIN (or possibly a separate power that defaults to VIN, but the user could specify their own). On the analog pin side, it would be useful to bring out Agnd and/or AREF.

For a larger form factor, consider having logical breakouts in addition to the normal pin breakouts to bring out the 6 UART lines, 4 i2c buses, 2 i2s buses, 3 spi buses, 2 CAN buses). For the i2c buses, it would be helpful to have a way to solder in pull-up resistors.

In addition to 5.5mm power jack, it may be useful to have a 2 pin JST header for connecting lipos. Having an area for lipo charger would be useful (perhaps setup for the Adafruit Pro Trinket Backpack).I hacked around some more on it to address some of the issues mentioned, plus add a few things, but so far tried to avoid adding the kitchen sink.

I added more room behind the back end of the board to hopefully allow insertions and removals of SD card.

I did not yet widen the board to allow me to choose additional power capabilities, like choose what voltage goes to the pins. Nor did I extend on the capbilities for ARef and AGnd. Note: those pins are brought out and labeled AG and RF.

I played around some with adding the JST connector and allow run from 1 lipo and maybe add charging circuit, but punted for now as I would not have +5v, not sure how best to power things, like probably separate powering of Teensy from other stuff. I did add a 2x2 connector with GND and VIN, so you can use those to jumper in or out of the board. My thinking is if you need this, the board should still be compatible with the stuff up on Tindie...

Added PGM button.

Added .127 2 pin connector area going to VBAT/GND to allow RTC battery backup. Not sure what part to use there, but this appears to be the size of connector of some of these batteries. Example ones from ODRoid.

One Kitchen Sink: I like LEDs, like Neopixels, So added on Two level converters (and gates like prop shield). Also used IO pins associated with SPI2 CLK/MOSI, so can use dotstar as well (I believe).

Board currently looks something like:

There are more things I would like Sound... But not sure of best approach now, also would need to increase size of board to add speaker, so decided to wait on this to see what options we might have. So I ordered a set of 4 of these from Digistump, for about $24.

Now back to playing with the hardware and software.