Another round of updates to various boards, and some new ones! Getting closer to finalizing some of these. Feedback still welcome

but ordering test boards very soon

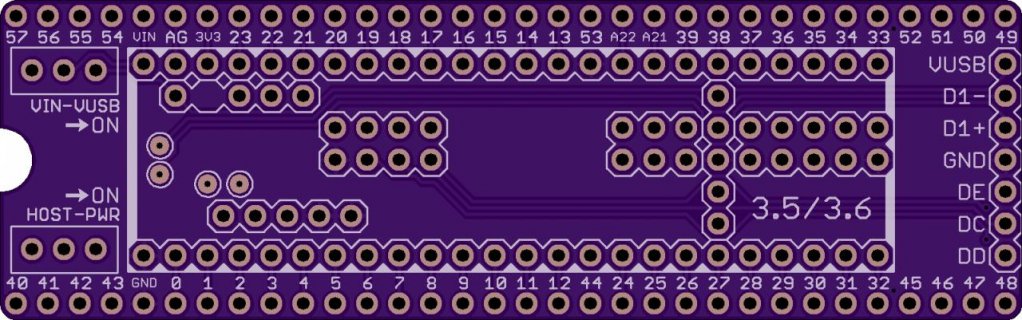

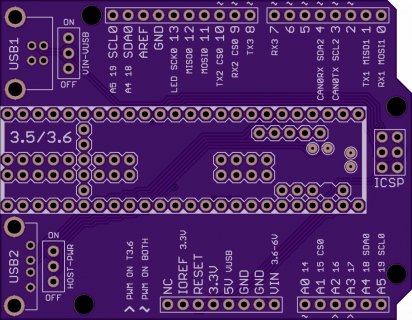

DIP-64

View attachment 8645

- Slightly more logical pin layout--the additional pins are now fully sequential counter-clockwise

- Removed the USB micro jack--there wasn't really physical room for it, and it'd have been very annoying to hand-solder

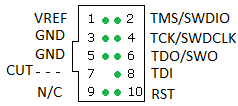

- Reordered SWD pins--as per suggestion by mundungus, DE is now next to GND

- Changed markings of SWD pins--to stay consistent with the Teensy cards (DE, DD, DC)

- Added orientation cutout--Just for the fun of it, I mean, it's DIP form factor after all...

- Might be finished?

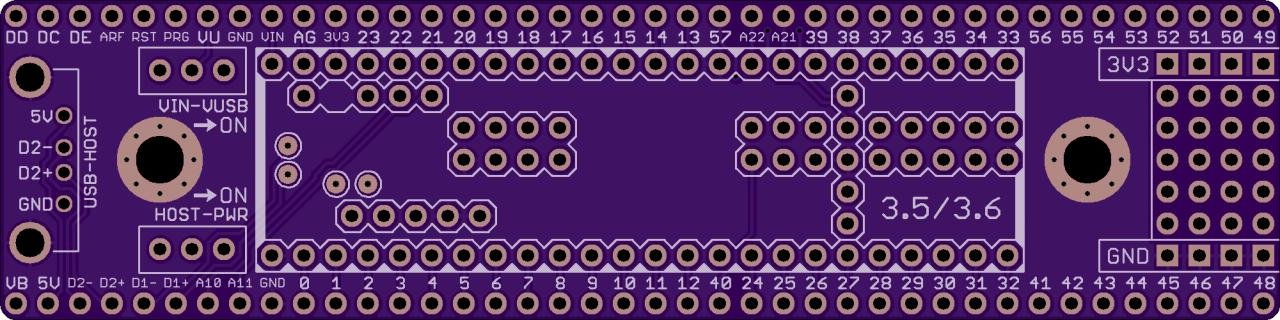

Standard

View attachment 8646

- Also new slightly different pin layout--Teensy centered, moved some digital pins and A10/A11, VBAT, and AREF

- Changed mounting hole locations--They now have 2.9" spacing, no longer symmetrical, due to other layout changes

- Went back to full-size USB jack--Much much easier to solder, no need for an OTG adapter, should have room with onboard USB if using any right-angle micro-USB cable, but I still need to verify this with test cables & boards (once they've been made)

- Moved switch locations--To make room for the USB jack and to stay consistent with the DIP-64 board

- Slightly smaller proto area--down to 20 pins, due to the other layout adjustments

- Looking into JTAG header (see earlier posts)

- Looking into AREF source (see earlier posts)

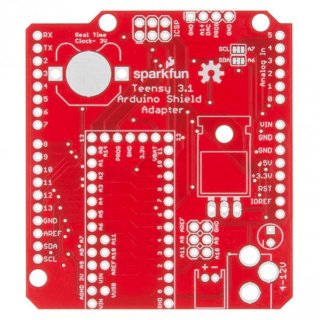

Arduino

View attachment 8647

This is a new one, an Uno-sized (R3) adapter board. This is my first take on it. Powered via USB. Onboard USB is broken out to full-size USB-B jack, so blockage by the ICSP header isn't an issue, and the micro SD is easily accessible. T3.6 host port broken out to full-size USB-A jack. Switches same as other breakouts. Seems like there's plenty of room for other stuff being broken out into non-Arduino-standard headers--thoughts on this?

I'm also working on a

Mega/Due-sized version, expanded from this one, but I don't have a draft finished yet.

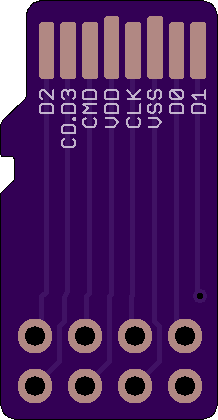

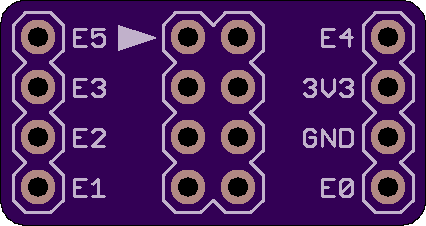

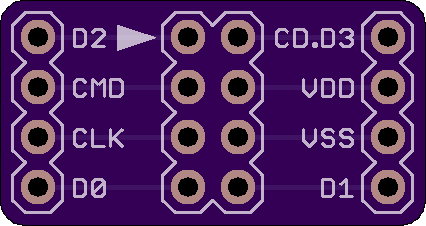

Micro SD Kit

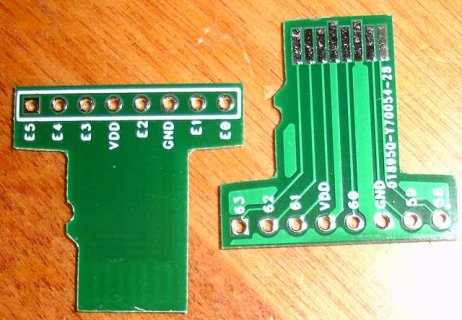

View attachment 8648 View attachment 8649

View attachment 8650 View attachment 8651

Also new, and based partially on some previously discussed designs. Comes with two boards, designed to be attached to each other with an 8-pin ribbon cable (thinking 6" or 12"). The board that goes into the breadboard is designed so it can be flipped either way: one orientation shows the Teensy pins, the other shows the SD card pins--this decision needs to be made before soldering on the headers, since only the markings that end up on the "top" (exposed) side will be accurate. Played with using keyed/shrouded headers but decided they took up too much extra space.

Socket Kit

Planning to make a kit for any of the above boards to allow the Teensy to be socketed instead of permanently soldered. Would include all necessary female headers and alternate-size pogo pins, etc.