Hello everyone!

I have recently decided to build my own GameCube controller for Super Smash Brothers Melee.

I posted a thread about this on a different forum, here is the link if you want to look at it: http://forum.allaboutcircuits.com/threads/using-arcade-buttons-to-replace-an-analog-joystick.128295/

This is a video of the design I am trying to build: https://www.youtube.com/watch?v=UM-NKXS1m2I

Basically, I want to replace a 2 potentiometer joystick with 8 digital arcade buttons (4 cardinal directions, and 4 modifier buttons).

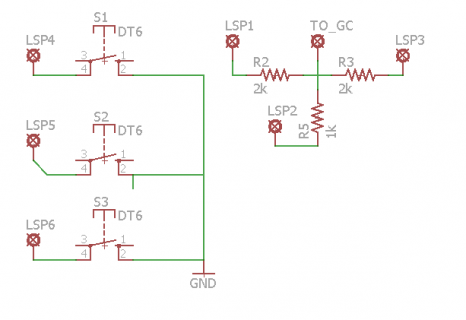

Here is how each potentiometer system would work:

- There are 4 buttons per potentiometer: one triggers full low, one triggers full high, and two are modifiers.

- The modifiers scale the output triggered by the low or high buttons to a configurable percentage from the middle (each modifier has its own percentage).

- The output to the potentiometer goes to the middle value when no buttons are pressed.

- If a either a low or high button is pressed after the other has been held down, the newer button press takes precedence.

I have some questions regarding hardware and software.

In the other thread I posted, I was given two suggestions. One was to output a PWM signal and filter it, and the other was to communicate with a digital potentiometer. I think a digital potentiometer seems like a much better idea. What do you think?

As for the code, I am plotting it out just using USB serial and watching my output there just to get my code right. I figure I can switch it to do whatever output I need later once I have the logic down. I am having some trouble though if anyone can help.

Right now, because of my mediocre knowledge of programming, I am resorting to using a bunch of if statements for the different cases of button combinations I can think of. This seems a bit clunky, is there a better way of doing this? Also, if I do use a digital potentiometer, is there any adverse effect to updating it constantly? Should I only be updating it when I need to or is it not a big deal? If it is a big deal, how can I write a system that only updates it when button changes are detected?

If anyone could give me some advice I would greatly appreciate it! Here is my incomplete code so far for reference:

I have recently decided to build my own GameCube controller for Super Smash Brothers Melee.

I posted a thread about this on a different forum, here is the link if you want to look at it: http://forum.allaboutcircuits.com/threads/using-arcade-buttons-to-replace-an-analog-joystick.128295/

This is a video of the design I am trying to build: https://www.youtube.com/watch?v=UM-NKXS1m2I

Basically, I want to replace a 2 potentiometer joystick with 8 digital arcade buttons (4 cardinal directions, and 4 modifier buttons).

Here is how each potentiometer system would work:

- There are 4 buttons per potentiometer: one triggers full low, one triggers full high, and two are modifiers.

- The modifiers scale the output triggered by the low or high buttons to a configurable percentage from the middle (each modifier has its own percentage).

- The output to the potentiometer goes to the middle value when no buttons are pressed.

- If a either a low or high button is pressed after the other has been held down, the newer button press takes precedence.

I have some questions regarding hardware and software.

In the other thread I posted, I was given two suggestions. One was to output a PWM signal and filter it, and the other was to communicate with a digital potentiometer. I think a digital potentiometer seems like a much better idea. What do you think?

As for the code, I am plotting it out just using USB serial and watching my output there just to get my code right. I figure I can switch it to do whatever output I need later once I have the logic down. I am having some trouble though if anyone can help.

Right now, because of my mediocre knowledge of programming, I am resorting to using a bunch of if statements for the different cases of button combinations I can think of. This seems a bit clunky, is there a better way of doing this? Also, if I do use a digital potentiometer, is there any adverse effect to updating it constantly? Should I only be updating it when I need to or is it not a big deal? If it is a big deal, how can I write a system that only updates it when button changes are detected?

If anyone could give me some advice I would greatly appreciate it! Here is my incomplete code so far for reference:

Code:

void writeToDigitalPot (double inputValue);

int getPotOutput (boolean potLowCurrent,

boolean potLowPrevious,

boolean potHighCurrent,

boolean potHighPrevious);

// Buttons:

const int Left = 0;

const int Right = 1;

const int Down = 2;

const int Up = 3;

const int xMod1 = 4;

const int xMod2 = 5;

const int yMod1 = 6;

const int yMod2 = 7;

boolean LeftPreviousValue = 1;

boolean RightPreviousValue = 1;

void setup()

{

Serial.begin (9600);

pinMode (Left, INPUT_PULLUP);

pinMode (Right, INPUT_PULLUP);

}

void loop()

{

//---------Left Stick X-Axis----------

boolean LeftCurrentValue = digitalRead (Left);

boolean RightCurrentValue = digitalRead (Right);

int xAxisPotValue = getPotOutput (LeftCurrentValue,

LeftPreviousValue,

RightCurrentValue,

RightPreviousValue);

writeToDigitalPot (xAxisPotValue);

LeftPreviousValue = LeftCurrentValue;

RightPreviousValue = RightCurrentValue;

//---------Left Stick Y-Axis----------

}

void writeToDigitalPot (int inputValue)

{

Serial.println (inputValue);

delay (200);

}

int getPotOutput (boolean potLowCurrent,

boolean potLowPrevious,

boolean potHighCurrent,

boolean potHighPrevious)

{

int potOutput = 129;

boolean potLowJustPushed = potLowCurrent == 0

&& potLowPrevious == 1;

boolean potLowJustReleased = potLowCurrent == 1

&& potLowPrevious == 0;

boolean potHighJustPushed = potHighCurrent == 0

&& potHighPrevious == 1;

boolean potHighJustReleased = potHighCurrent == 1

&& potHighPrevious == 0;

if (potLowJustPushed)

{

potOutput = 0;

}

if (potHighJustPushed)

{

potOutput = 257;

}

if (potLowJustPushed && potHighJustPushed)

{

potOutput = 129;

}

if (potHighJustReleased && potLowCurrent == 0)

{

potOutput = 0;

}

if (potLowJustReleased && potHighCurrent == 0)

{

potOutput = 257;

}

if (potHighJustReleased && potLowCurrent == 1)

{

potOutput = 129;

}

if (potLowJustReleased && potHighCurrent == 1)

{

potOutput = 129;

}

if (potLowJustReleased && potHighJustReleased)

{

potOutput = 129;

}

return potOutput;

}