Hi Guys,

I am currently planning my first project which is a 32 channel mixing desk to use for mixing music, but have currently hit a brick wall as i'm quite new to all of this.

I am concentrating on designing one channel of the desk at the minute to keep things simple, then its just a case of duplicating it another 31 times.

I have a few questions if anybody would be kind enough to clear them up for me please

Question 1

First of all I am planning on using a rotary encoder on each channel to control the panning of instruments to the left and right, I want to know if I can use an LED ring around the encoder to determine the pan position rather than a line on a knob, and if so can I get 1 led to stay lit at the 12oclock position on the led ring for each channel until I turn the knob left or right.

Question 2

If I was to open a music project that already has panning on instruments in place would it be easy enough for the led rings around the encoders to pick up on this and display them accordingly?

Question 3

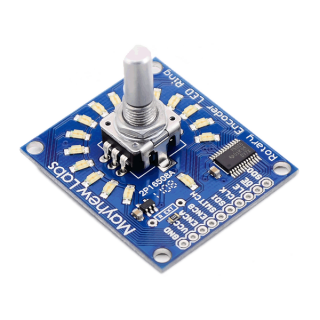

The picture below is exactly what I am looking for but unfortunately it has been discontinued so does anybody have any idea if I can get something similar elsewhere.

Thanks!

I am currently planning my first project which is a 32 channel mixing desk to use for mixing music, but have currently hit a brick wall as i'm quite new to all of this.

I am concentrating on designing one channel of the desk at the minute to keep things simple, then its just a case of duplicating it another 31 times.

I have a few questions if anybody would be kind enough to clear them up for me please

Question 1

First of all I am planning on using a rotary encoder on each channel to control the panning of instruments to the left and right, I want to know if I can use an LED ring around the encoder to determine the pan position rather than a line on a knob, and if so can I get 1 led to stay lit at the 12oclock position on the led ring for each channel until I turn the knob left or right.

Question 2

If I was to open a music project that already has panning on instruments in place would it be easy enough for the led rings around the encoders to pick up on this and display them accordingly?

Question 3

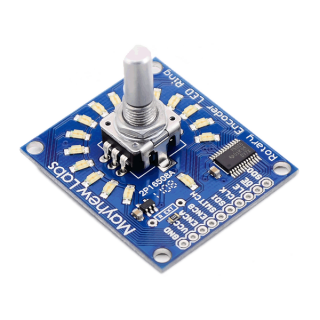

The picture below is exactly what I am looking for but unfortunately it has been discontinued so does anybody have any idea if I can get something similar elsewhere.

Thanks!