laptophead

Well-known member

I wrote this simple Servo algorithm based on a DC motor bringing a pot back to the central value.

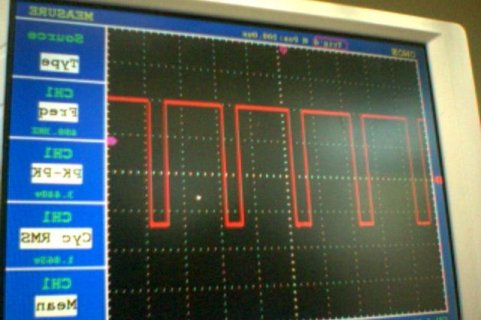

While the (GapFront >= 50) gives me a clean 200 PWM, the other condition (GapFront <= -50) gives me a scrambled signal.

I included the pics of the nice and bad PWM.

What I tried and did not work:

Moved pin 22 to pin 2.

Used a 100 digitalWrite val instead of 200;.

Please help.

Thanks a lot.

While the (GapFront >= 50) gives me a clean 200 PWM, the other condition (GapFront <= -50) gives me a scrambled signal.

I included the pics of the nice and bad PWM.

What I tried and did not work:

Moved pin 22 to pin 2.

Used a 100 digitalWrite val instead of 200;.

Please help.

Thanks a lot.