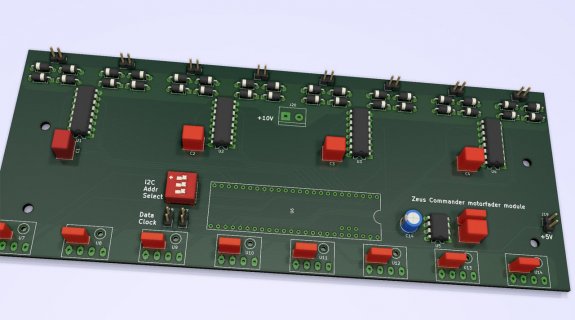

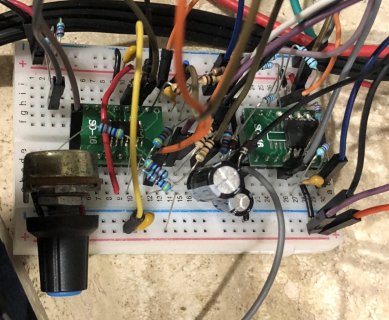

While strip board is nice to develop and test stuff there comes a point when you just have to create proper circuit boards for your project so I took the time to learn how to use

KiCad and designed boards for my sequencer project. I’m not an electrical engineer but I tried to design the board as best as I could keeping the high current motor stuff as far away as possible from the fader input. The thermal relief for the four ground pins of the L293B was removed as the copper ground plane is used as a heatsink, same for the high current connections. The copper layers are 35µm.

This is what the KiCad 3D render looks like:

View attachment 15434

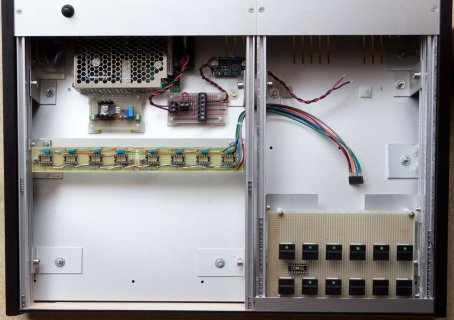

And here’s a picture of two boards for a total of 16 motor faders:

View attachment 15433

Here’s the KiCad project:

View attachment 15432

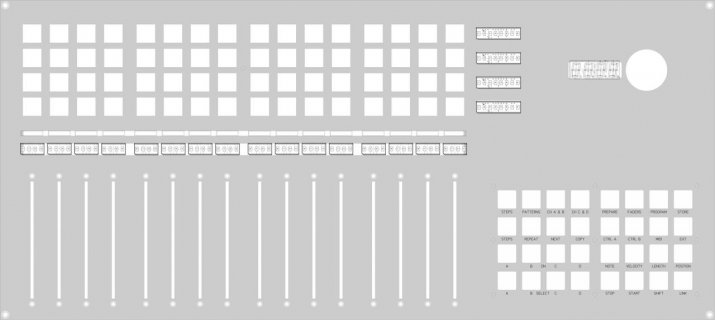

The updated sketch for the panel:

View attachment 15435

Any comments on the board design are welcome. There's at least one issue that needs fixing; the 100µf capacitor on the analog reference should be moved, the USB connector barely fits. Note that he pin numbers in the schematic do not match as I had to move around pin connections to fit everything on the PCB, the sketch contains the correct numbers.

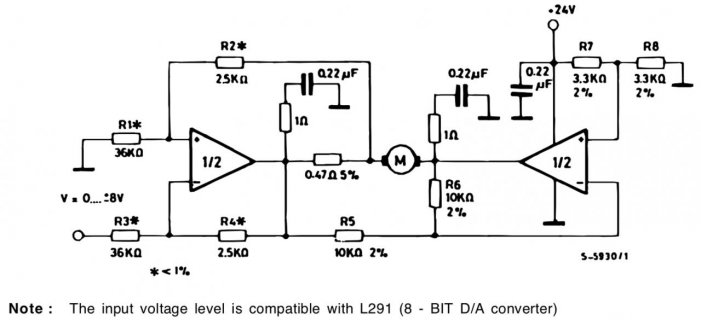

The new setup has completely separate power supplies for the 5V logic and the 10V motor supply and the faders all have 10nF decoupling caps directly on the input, the result is that the response of the faders is most excellent. The link mode is working flawlessly now, completely stable values while 15 faders follow the one that’s moved. It's really nice to see how 15 faders move like a perfect Roman cohort as they follow the fader that's moved.