/* MPU6050 Basic Example with IMU

by: Kris Winer

date: May 10, 2014

license: Beerware - Use this code however you'd like. If you

find it useful you can buy me a beer some time.

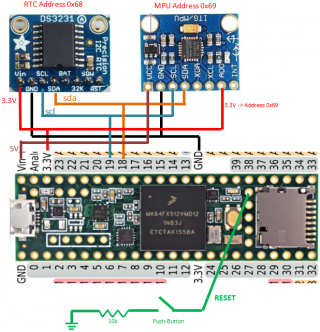

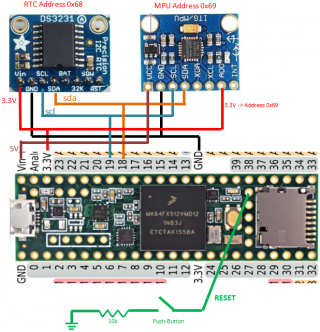

SDA and SCL should have external pull-up resistors (to 3.3V).

10k resistors worked for me. They should be on the breakout

board.

Hardware setup:

MPU6050 Breakout --------- Arduino

3.3V --------------------- 3.3V

SDA ----------------------- A4

SCL ----------------------- A5

GND ---------------------- GND

#include<i2c_t3.h>

// Using NOKIA 5110 monochrome 84 x 48 pixel display

// pin 9 - Serial clock out (SCLK)

// pin 8 - Serial data out (DIN)

// pin 7 - Data/Command select (D/C)

// pin 5 - LCD chip select (CS)

// pin 6 - LCD reset (RST)

// Define registers per MPU6050, Register Map and Descriptions, Rev 4.2, 08/19/2013 6 DOF Motion sensor fusion device

// Invensense Inc., www.invensense.com

// See also MPU-6050 Register Map and Descriptions, Revision 4.0, RM-MPU-6050A-00, 9/12/2012 for registers not listed in

// above document; the MPU6050 and MPU 9150 are virtually identical but the latter has an on-board magnetic sensor

//

#define XGOFFS_TC 0x00 // Bit 7 PWR_MODE, bits 6:1 XG_OFFS_TC, bit 0 OTP_BNK_VLD

#define YGOFFS_TC 0x01

#define ZGOFFS_TC 0x02

#define X_FINE_GAIN 0x03 // [7:0] fine gain

#define Y_FINE_GAIN 0x04

#define Z_FINE_GAIN 0x05

#define XA_OFFSET_H 0x06 // User-defined trim values for accelerometer

#define XA_OFFSET_L_TC 0x07

#define YA_OFFSET_H 0x08

#define YA_OFFSET_L_TC 0x09

#define ZA_OFFSET_H 0x0A

#define ZA_OFFSET_L_TC 0x0B

#define SELF_TEST_X 0x0D

#define SELF_TEST_Y 0x0E

#define SELF_TEST_Z 0x0F

#define SELF_TEST_A 0x10

#define XG_OFFS_USRH 0x13 // User-defined trim values for gyroscope; supported in MPU-6050?

#define XG_OFFS_USRL 0x14

#define YG_OFFS_USRH 0x15

#define YG_OFFS_USRL 0x16

#define ZG_OFFS_USRH 0x17

#define ZG_OFFS_USRL 0x18

#define SMPLRT_DIV 0x19

#define CONFIG 0x1A

#define GYRO_CONFIG 0x1B

#define ACCEL_CONFIG 0x1C

#define FF_THR 0x1D // Free-fall

#define FF_DUR 0x1E // Free-fall

#define MOT_THR 0x1F // Motion detection threshold bits [7:0]

#define MOT_DUR 0x20 // Duration counter threshold for motion interrupt generation, 1 kHz rate, LSB = 1 ms

#define ZMOT_THR 0x21 // Zero-motion detection threshold bits [7:0]

#define ZRMOT_DUR 0x22 // Duration counter threshold for zero motion interrupt generation, 16 Hz rate, LSB = 64 ms

#define FIFO_EN 0x23

#define I2C_MST_CTRL 0x24

#define I2C_SLV0_ADDR 0x25

#define I2C_SLV0_REG 0x26

#define I2C_SLV0_CTRL 0x27

#define I2C_SLV1_ADDR 0x28

#define I2C_SLV1_REG 0x29

#define I2C_SLV1_CTRL 0x2A

#define I2C_SLV2_ADDR 0x2B

#define I2C_SLV2_REG 0x2C

#define I2C_SLV2_CTRL 0x2D

#define I2C_SLV3_ADDR 0x2E

#define I2C_SLV3_REG 0x2F

#define I2C_SLV3_CTRL 0x30

#define I2C_SLV4_ADDR 0x31

#define I2C_SLV4_REG 0x32

#define I2C_SLV4_DO 0x33

#define I2C_SLV4_CTRL 0x34

#define I2C_SLV4_DI 0x35

#define I2C_MST_STATUS 0x36

#define INT_PIN_CFG 0x37

#define INT_ENABLE 0x38

#define DMP_INT_STATUS 0x39 // Check DMP interrupt

#define INT_STATUS 0x3A

#define ACCEL_XOUT_H 0x3B

#define ACCEL_XOUT_L 0x3C

#define ACCEL_YOUT_H 0x3D

#define ACCEL_YOUT_L 0x3E

#define ACCEL_ZOUT_H 0x3F

#define ACCEL_ZOUT_L 0x40

#define TEMP_OUT_H 0x41

#define TEMP_OUT_L 0x42

#define GYRO_XOUT_H 0x43

#define GYRO_XOUT_L 0x44

#define GYRO_YOUT_H 0x45

#define GYRO_YOUT_L 0x46

#define GYRO_ZOUT_H 0x47

#define GYRO_ZOUT_L 0x48

#define EXT_SENS_DATA_00 0x49

#define EXT_SENS_DATA_01 0x4A

#define EXT_SENS_DATA_02 0x4B

#define EXT_SENS_DATA_03 0x4C

#define EXT_SENS_DATA_04 0x4D

#define EXT_SENS_DATA_05 0x4E

#define EXT_SENS_DATA_06 0x4F

#define EXT_SENS_DATA_07 0x50

#define EXT_SENS_DATA_08 0x51

#define EXT_SENS_DATA_09 0x52

#define EXT_SENS_DATA_10 0x53

#define EXT_SENS_DATA_11 0x54

#define EXT_SENS_DATA_12 0x55

#define EXT_SENS_DATA_13 0x56

#define EXT_SENS_DATA_14 0x57

#define EXT_SENS_DATA_15 0x58

#define EXT_SENS_DATA_16 0x59

#define EXT_SENS_DATA_17 0x5A

#define EXT_SENS_DATA_18 0x5B

#define EXT_SENS_DATA_19 0x5C

#define EXT_SENS_DATA_20 0x5D

#define EXT_SENS_DATA_21 0x5E

#define EXT_SENS_DATA_22 0x5F

#define EXT_SENS_DATA_23 0x60

#define MOT_DETECT_STATUS 0x61

#define I2C_SLV0_DO 0x63

#define I2C_SLV1_DO 0x64

#define I2C_SLV2_DO 0x65

#define I2C_SLV3_DO 0x66

#define I2C_MST_DELAY_CTRL 0x67

#define SIGNAL_PATH_RESET 0x68

#define MOT_DETECT_CTRL 0x69

#define USER_CTRL 0x6A // Bit 7 enable DMP, bit 3 reset DMP

#define PWR_MGMT_1 0x6B // Device defaults to the SLEEP mode

#define PWR_MGMT_2 0x6C

#define DMP_BANK 0x6D // Activates a specific bank in the DMP

#define DMP_RW_PNT 0x6E // Set read/write pointer to a specific start address in specified DMP bank

#define DMP_REG 0x6F // Register in DMP from which to read or to which to write

#define DMP_REG_1 0x70

#define DMP_REG_2 0x71

#define FIFO_COUNTH 0x72

#define FIFO_COUNTL 0x73

#define FIFO_R_W 0x74

#define WHO_AM_I_MPU6050 0x75 // Should return 0x68

// Using the GY-521 breakout board, I set ADO to 0 by grounding through a 4k7 resistor

// Seven-bit device address is 110100 for ADO = 0 and 110101 for ADO = 1

#define ADO 0

#if ADO

#define MPU6050_ADDRESS 0x69 // Device address when ADO = 1

#else

#define MPU6050_ADDRESS 0x68 // Device address when ADO = 0

#endif

// Set initial input parameters

enum Ascale {

AFS_2G = 0,

AFS_4G,

AFS_8G,

AFS_16G

};

enum Gscale {

GFS_250DPS = 0,

GFS_500DPS,

GFS_1000DPS,

GFS_2000DPS

};

// Specify sensor full scale

int Gscale = GFS_250DPS;

int Ascale = AFS_2G;

float aRes, gRes; // scale resolutions per LSB for the sensors

// Pin definitions

int intPin = 12; // These can be changed, 2 and 3 are the Arduinos ext int pins

#define blinkPin 13 // Blink LED on Teensy or Pro Mini when updating

boolean blinkOn = false;

int16_t accelCount[3]; // Stores the 16-bit signed accelerometer sensor output

float ax, ay, az; // Stores the real accel value in g's

int16_t gyroCount[3]; // Stores the 16-bit signed gyro sensor output

float gx, gy, gz; // Stores the real gyro value in degrees per seconds

float gyroBias[3] = {0, 0, 0}, accelBias[3] = {0, 0, 0}; // Bias corrections for gyro and accelerometer

int16_t tempCount; // Stores the real internal chip temperature in degrees Celsius

float temperature;

float SelfTest[6];

uint32_t delt_t = 0; // used to control display output rate

uint32_t count = 0; // used to control display output rate

// parameters for 6 DoF sensor fusion calculations

float GyroMeasError = PI * (40.0f / 180.0f); // gyroscope measurement error in rads/s (start at 60 deg/s), then reduce after ~10 s to 3

float beta = sqrt(3.0f / 4.0f) * GyroMeasError; // compute beta

float GyroMeasDrift = PI * (2.0f / 180.0f); // gyroscope measurement drift in rad/s/s (start at 0.0 deg/s/s)

float zeta = sqrt(3.0f / 4.0f) * GyroMeasDrift; // compute zeta, the other free parameter in the Madgwick scheme usually set to a small or zero value

float pitch, yaw, roll;

float deltat = 0.0f; // integration interval for both filter schemes

uint32_t lastUpdate = 0, firstUpdate = 0; // used to calculate integration interval

uint32_t Now = 0; // used to calculate integration interval

float q[4] = {1.0f, 0.0f, 0.0f, 0.0f}; // vector to hold quaternion

void setup()

{

Wire1.begin();

Serial.begin(38400);

// Set up the interrupt pin, its set as active high, push-pull

pinMode(intPin, INPUT);

digitalWrite(intPin, LOW);

pinMode(blinkPin, OUTPUT);

digitalWrite(blinkPin, HIGH);

uint8_t c = readByte(MPU6050_ADDRESS, WHO_AM_I_MPU6050);

if (c == 0x68) // WHO_AM_I should always be 0x68

{

Serial.println("MPU6050 is online...");

MPU6050SelfTest(SelfTest); // Start by performing self test and reporting values

// Serial.print("x-axis self test: acceleration trim within : "); Serial.print(SelfTest[0],1); Serial.println("% of factory value");

// Serial.print("y-axis self test: acceleration trim within : "); Serial.print(SelfTest[1],1); Serial.println("% of factory value");

// Serial.print("z-axis self test: acceleration trim within : "); Serial.print(SelfTest[2],1); Serial.println("% of factory value");

// Serial.print("x-axis self test: gyration trim within : "); Serial.print(SelfTest[3],1); Serial.println("% of factory value");

// Serial.print("y-axis self test: gyration trim within : "); Serial.print(SelfTest[4],1); Serial.println("% of factory value");

// Serial.print("z-axis self test: gyration trim within : "); Serial.print(SelfTest[5],1); Serial.println("% of factory value");

if(SelfTest[0] < 1.0f && SelfTest[1] < 1.0f && SelfTest[2] < 1.0f && SelfTest[3] < 1.0f && SelfTest[4] < 1.0f && SelfTest[5] < 1.0f) {

delay(1000);

calibrateMPU6050(gyroBias, accelBias); // Calibrate gyro and accelerometers, load biases in bias registers

initMPU6050(); Serial.println("MPU6050 initialized for active data mode...."); // Initialize device for active mode read of acclerometer, gyroscope, and temperature

}

else

{

Serial.print("Could not connect to MPU6050: 0x");

Serial.println(c, HEX);

while(1) ; // Loop forever if communication doesn't happen

}

}

}

void loop()

{

// If data ready bit set, all data registers have new data

if(readByte(MPU6050_ADDRESS, INT_STATUS) & 0x01) { // check if data ready interrupt

readAccelData(accelCount); // Read the x/y/z adc values

getAres();

// Now we'll calculate the accleration value into actual g's

ax = (float)accelCount[0]*aRes; // get actual g value, this depends on scale being set

ay = (float)accelCount[1]*aRes;

az = (float)accelCount[2]*aRes;

readGyroData(gyroCount); // Read the x/y/z adc values

getGres();

// Calculate the gyro value into actual degrees per second

gx = (float)gyroCount[0]*gRes; // get actual gyro value, this depends on scale being set

gy = (float)gyroCount[1]*gRes;

gz = (float)gyroCount[2]*gRes;

tempCount = readTempData(); // Read the x/y/z adc values

temperature = ((float) tempCount) / 340. + 36.53; // Temperature in degrees Centigrade

}

Now = micros();

deltat = ((Now - lastUpdate)/1000000.0f); // set integration time by time elapsed since last filter update

lastUpdate = Now;

// if(lastUpdate - firstUpdate > 10000000uL) {

// beta = 0.041; // decrease filter gain after stabilized

// zeta = 0.015; // increase gyro bias drift gain after stabilized

// }

// Pass gyro rate as rad/s

MadgwickQuaternionUpdate(ax, ay, az, gx*PI/180.0f, gy*PI/180.0f, gz*PI/180.0f);

// Serial print and/or display at 0.5 s rate independent of data rates

delt_t = millis() - count;

if (delt_t > 500) { // update LCD once per half-second independent of read rate

digitalWrite(blinkPin, blinkOn);

/*

Serial.print("ax = "); Serial.print((int)1000*ax);

Serial.print(" ay = "); Serial.print((int)1000*ay);

Serial.print(" az = "); Serial.print((int)1000*az); Serial.println(" mg");

Serial.print("gx = "); Serial.print( gx, 1);

Serial.print(" gy = "); Serial.print( gy, 1);

Serial.print(" gz = "); Serial.print( gz, 1); Serial.println(" deg/s");

Serial.print("q0 = "); Serial.print(q[0]);

Serial.print(" qx = "); Serial.print(q[1]);

Serial.print(" qy = "); Serial.print(q[2]);

Serial.print(" qz = "); Serial.println(q[3]);

*/

// Define output variables from updated quaternion---these are Tait-Bryan angles, commonly used in aircraft orientation.

// In this coordinate system, the positive z-axis is down toward Earth.

// Yaw is the angle between Sensor x-axis and Earth magnetic North (or true North if corrected for local declination, looking down on the sensor positive yaw is counterclockwise.

// Pitch is angle between sensor x-axis and Earth ground plane, toward the Earth is positive, up toward the sky is negative.

// Roll is angle between sensor y-axis and Earth ground plane, y-axis up is positive roll.

// These arise from the definition of the homogeneous rotation matrix constructed from quaternions.

// Tait-Bryan angles as well as Euler angles are non-commutative; that is, the get the correct orientation the rotations must be

// applied in the correct order which for this configuration is yaw, pitch, and then roll.

// For more see http://en.wikipedia.org/wiki/Conversion_between_quaternions_and_Euler_angles which has additional links.

yaw = atan2(2.0f * (q[1] * q[2] + q[0] * q[3]), q[0] * q[0] + q[1] * q[1] - q[2] * q[2] - q[3] * q[3]);

pitch = -asin(2.0f * (q[1] * q[3] - q[0] * q[2]));

roll = atan2(2.0f * (q[0] * q[1] + q[2] * q[3]), q[0] * q[0] - q[1] * q[1] - q[2] * q[2] + q[3] * q[3]);

pitch *= 180.0f / PI;

yaw *= 180.0f / PI;

roll *= 180.0f / PI;

// Serial.print("Yaw, Pitch, Roll: ");

Serial.print(yaw, 2);

Serial.print(", ");

Serial.print(pitch, 2);

Serial.print(", ");

Serial.println(roll, 2);

// Serial.print("average rate = "); Serial.print(1.0f/deltat, 2); Serial.println(" Hz");

blinkOn = ~blinkOn;

count = millis();

}

}

//===================================================================================================================

//====== Set of useful function to access acceleratio, gyroscope, and temperature data

//===================================================================================================================

void getGres() {

switch (Gscale)

{

// Possible gyro scales (and their register bit settings) are:

// 250 DPS (00), 500 DPS (01), 1000 DPS (10), and 2000 DPS (11).

// Here's a bit of an algorith to calculate DPS/(ADC tick) based on that 2-bit value:

case GFS_250DPS:

gRes = 250.0/32768.0;

break;

case GFS_500DPS:

gRes = 500.0/32768.0;

break;

case GFS_1000DPS:

gRes = 1000.0/32768.0;

break;

case GFS_2000DPS:

gRes = 2000.0/32768.0;

break;

}

}

void getAres() {

switch (Ascale)

{

// Possible accelerometer scales (and their register bit settings) are:

// 2 Gs (00), 4 Gs (01), 8 Gs (10), and 16 Gs (11).

// Here's a bit of an algorith to calculate DPS/(ADC tick) based on that 2-bit value:

case AFS_2G:

aRes = 2.0/32768.0;

break;

case AFS_4G:

aRes = 4.0/32768.0;

break;

case AFS_8G:

aRes = 8.0/32768.0;

break;

case AFS_16G:

aRes = 16.0/32768.0;

break;

}

}

void readAccelData(int16_t * destination)

{

uint8_t rawData[6]; // x/y/z accel register data stored here

readBytes(MPU6050_ADDRESS, ACCEL_XOUT_H, 6, &rawData[0]); // Read the six raw data registers into data array

destination[0] = (int16_t)((rawData[0] << 8) | rawData[1]) ; // Turn the MSB and LSB into a signed 16-bit value

destination[1] = (int16_t)((rawData[2] << 8) | rawData[3]) ;

destination[2] = (int16_t)((rawData[4] << 8) | rawData[5]) ;

}

void readGyroData(int16_t * destination)

{

uint8_t rawData[6]; // x/y/z gyro register data stored here

readBytes(MPU6050_ADDRESS, GYRO_XOUT_H, 6, &rawData[0]); // Read the six raw data registers sequentially into data array

destination[0] = (int16_t)((rawData[0] << 8) | rawData[1]) ; // Turn the MSB and LSB into a signed 16-bit value

destination[1] = (int16_t)((rawData[2] << 8) | rawData[3]) ;

destination[2] = (int16_t)((rawData[4] << 8) | rawData[5]) ;

}

int16_t readTempData()

{

uint8_t rawData[2]; // x/y/z gyro register data stored here

readBytes(MPU6050_ADDRESS, TEMP_OUT_H, 2, &rawData[0]); // Read the two raw data registers sequentially into data array

return ((int16_t)rawData[0]) << 8 | rawData[1] ; // Turn the MSB and LSB into a 16-bit value

}

// Configure the motion detection control for low power accelerometer mode

void LowPowerAccelOnlyMPU6050()

{

// The sensor has a high-pass filter necessary to invoke to allow the sensor motion detection algorithms work properly

// Motion detection occurs on free-fall (acceleration below a threshold for some time for all axes), motion (acceleration

// above a threshold for some time on at least one axis), and zero-motion toggle (acceleration on each axis less than a

// threshold for some time sets this flag, motion above the threshold turns it off). The high-pass filter takes gravity out

// consideration for these threshold evaluations; otherwise, the flags would be set all the time!

uint8_t c = readByte(MPU6050_ADDRESS, PWR_MGMT_1);

writeByte(MPU6050_ADDRESS, PWR_MGMT_1, c & ~0x30); // Clear sleep and cycle bits [5:6]

writeByte(MPU6050_ADDRESS, PWR_MGMT_1, c | 0x30); // Set sleep and cycle bits [5:6] to zero to make sure accelerometer is running

c = readByte(MPU6050_ADDRESS, PWR_MGMT_2);

writeByte(MPU6050_ADDRESS, PWR_MGMT_2, c & ~0x38); // Clear standby XA, YA, and ZA bits [3:5]

writeByte(MPU6050_ADDRESS, PWR_MGMT_2, c | 0x00); // Set XA, YA, and ZA bits [3:5] to zero to make sure accelerometer is running

c = readByte(MPU6050_ADDRESS, ACCEL_CONFIG);

writeByte(MPU6050_ADDRESS, ACCEL_CONFIG, c & ~0x07); // Clear high-pass filter bits [2:0]

// Set high-pass filter to 0) reset (disable), 1) 5 Hz, 2) 2.5 Hz, 3) 1.25 Hz, 4) 0.63 Hz, or 7) Hold

writeByte(MPU6050_ADDRESS, ACCEL_CONFIG, c | 0x00); // Set ACCEL_HPF to 0; reset mode disbaling high-pass filter

c = readByte(MPU6050_ADDRESS, CONFIG);

writeByte(MPU6050_ADDRESS, CONFIG, c & ~0x07); // Clear low-pass filter bits [2:0]

writeByte(MPU6050_ADDRESS, CONFIG, c | 0x00); // Set DLPD_CFG to 0; 260 Hz bandwidth, 1 kHz rate

c = readByte(MPU6050_ADDRESS, INT_ENABLE);

writeByte(MPU6050_ADDRESS, INT_ENABLE, c & ~0xFF); // Clear all interrupts

writeByte(MPU6050_ADDRESS, INT_ENABLE, 0x40); // Enable motion threshold (bits 5) interrupt only

// Motion detection interrupt requires the absolute value of any axis to lie above the detection threshold

// for at least the counter duration

writeByte(MPU6050_ADDRESS, MOT_THR, 0x80); // Set motion detection to 0.256 g; LSB = 2 mg

writeByte(MPU6050_ADDRESS, MOT_DUR, 0x01); // Set motion detect duration to 1 ms; LSB is 1 ms @ 1 kHz rate

delay (100); // Add delay for accumulation of samples

c = readByte(MPU6050_ADDRESS, ACCEL_CONFIG);

writeByte(MPU6050_ADDRESS, ACCEL_CONFIG, c & ~0x07); // Clear high-pass filter bits [2:0]

writeByte(MPU6050_ADDRESS, ACCEL_CONFIG, c | 0x07); // Set ACCEL_HPF to 7; hold the initial accleration value as a referance

c = readByte(MPU6050_ADDRESS, PWR_MGMT_2);

writeByte(MPU6050_ADDRESS, PWR_MGMT_2, c & ~0xC7); // Clear standby XA, YA, and ZA bits [3:5] and LP_WAKE_CTRL bits [6:7]

writeByte(MPU6050_ADDRESS, PWR_MGMT_2, c | 0x47); // Set wakeup frequency to 5 Hz, and disable XG, YG, and ZG gyros (bits [0:2])

c = readByte(MPU6050_ADDRESS, PWR_MGMT_1);

writeByte(MPU6050_ADDRESS, PWR_MGMT_1, c & ~0x20); // Clear sleep and cycle bit 5

writeByte(MPU6050_ADDRESS, PWR_MGMT_1, c | 0x20); // Set cycle bit 5 to begin low power accelerometer motion interrupts

}

void initMPU6050()

{

// wake up device-don't need this here if using calibration function below

// writeByte(MPU6050_ADDRESS, PWR_MGMT_1, 0x00); // Clear sleep mode bit (6), enable all sensors

// delay(100); // Delay 100 ms for PLL to get established on x-axis gyro; should check for PLL ready interrupt

// get stable time source

writeByte(MPU6050_ADDRESS, PWR_MGMT_1, 0x01); // Set clock source to be PLL with x-axis gyroscope reference, bits 2:0 = 001

// Configure Gyro and Accelerometer

// Disable FSYNC and set accelerometer and gyro bandwidth to 44 and 42 Hz, respectively;

// DLPF_CFG = bits 2:0 = 010; this sets the sample rate at 1 kHz for both

// Maximum delay time is 4.9 ms corresponding to just over 200 Hz sample rate

writeByte(MPU6050_ADDRESS, CONFIG, 0x03);

// Set sample rate = gyroscope output rate/(1 + SMPLRT_DIV)

writeByte(MPU6050_ADDRESS, SMPLRT_DIV, 0x04); // Use a 200 Hz rate; the same rate set in CONFIG above

// Set gyroscope full scale range

// Range selects FS_SEL and AFS_SEL are 0 - 3, so 2-bit values are left-shifted into positions 4:3

uint8_t c = readByte(MPU6050_ADDRESS, GYRO_CONFIG);

writeByte(MPU6050_ADDRESS, GYRO_CONFIG, c & ~0xE0); // Clear self-test bits [7:5]

writeByte(MPU6050_ADDRESS, GYRO_CONFIG, c & ~0x18); // Clear AFS bits [4:3]

writeByte(MPU6050_ADDRESS, GYRO_CONFIG, c | Gscale << 3); // Set full scale range for the gyro

// Set accelerometer configuration

c = readByte(MPU6050_ADDRESS, ACCEL_CONFIG);

writeByte(MPU6050_ADDRESS, ACCEL_CONFIG, c & ~0xE0); // Clear self-test bits [7:5]

writeByte(MPU6050_ADDRESS, ACCEL_CONFIG, c & ~0x18); // Clear AFS bits [4:3]

writeByte(MPU6050_ADDRESS, ACCEL_CONFIG, c | Ascale << 3); // Set full scale range for the accelerometer

// Configure Interrupts and Bypass Enable

// Set interrupt pin active high, push-pull, and clear on read of INT_STATUS, enable I2C_BYPASS_EN so additional chips

// can join the I2C bus and all can be controlled by the Arduino as master

writeByte(MPU6050_ADDRESS, INT_PIN_CFG, 0x22);

writeByte(MPU6050_ADDRESS, INT_ENABLE, 0x01); // Enable data ready (bit 0) interrupt

}

// Function which accumulates gyro and accelerometer data after device initialization. It calculates the average

// of the at-rest readings and then loads the resulting offsets into accelerometer and gyro bias registers.

void calibrateMPU6050(float * dest1, float * dest2)

{

uint8_t data[12]; // data array to hold accelerometer and gyro x, y, z, data

uint16_t ii, packet_count, fifo_count;

int32_t gyro_bias[3] = {0, 0, 0}, accel_bias[3] = {0, 0, 0};

// reset device, reset all registers, clear gyro and accelerometer bias registers

writeByte(MPU6050_ADDRESS, PWR_MGMT_1, 0x80); // Write a one to bit 7 reset bit; toggle reset device

delay(100);

// get stable time source

// Set clock source to be PLL with x-axis gyroscope reference, bits 2:0 = 001

writeByte(MPU6050_ADDRESS, PWR_MGMT_1, 0x01);

writeByte(MPU6050_ADDRESS, PWR_MGMT_2, 0x00);

delay(200);

// Configure device for bias calculation

writeByte(MPU6050_ADDRESS, INT_ENABLE, 0x00); // Disable all interrupts

writeByte(MPU6050_ADDRESS, FIFO_EN, 0x00); // Disable FIFO

writeByte(MPU6050_ADDRESS, PWR_MGMT_1, 0x00); // Turn on internal clock source

writeByte(MPU6050_ADDRESS, I2C_MST_CTRL, 0x00); // Disable I2C master

writeByte(MPU6050_ADDRESS, USER_CTRL, 0x00); // Disable FIFO and I2C master modes

writeByte(MPU6050_ADDRESS, USER_CTRL, 0x0C); // Reset FIFO and DMP

delay(15);

// Configure MPU6050 gyro and accelerometer for bias calculation

writeByte(MPU6050_ADDRESS, CONFIG, 0x01); // Set low-pass filter to 188 Hz

writeByte(MPU6050_ADDRESS, SMPLRT_DIV, 0x00); // Set sample rate to 1 kHz

writeByte(MPU6050_ADDRESS, GYRO_CONFIG, 0x00); // Set gyro full-scale to 250 degrees per second, maximum sensitivity

writeByte(MPU6050_ADDRESS, ACCEL_CONFIG, 0x00); // Set accelerometer full-scale to 2 g, maximum sensitivity

uint16_t gyrosensitivity = 131; // = 131 LSB/degrees/sec

uint16_t accelsensitivity = 16384; // = 16384 LSB/g

// Configure FIFO to capture accelerometer and gyro data for bias calculation

writeByte(MPU6050_ADDRESS, USER_CTRL, 0x40); // Enable FIFO

writeByte(MPU6050_ADDRESS, FIFO_EN, 0x78); // Enable gyro and accelerometer sensors for FIFO (max size 1024 bytes in MPU-6050)

delay(80); // accumulate 80 samples in 80 milliseconds = 960 bytes

// At end of sample accumulation, turn off FIFO sensor read

writeByte(MPU6050_ADDRESS, FIFO_EN, 0x00); // Disable gyro and accelerometer sensors for FIFO

readBytes(MPU6050_ADDRESS, FIFO_COUNTH, 2, &data[0]); // read FIFO sample count

fifo_count = ((uint16_t)data[0] << 8) | data[1];

packet_count = fifo_count/12;// How many sets of full gyro and accelerometer data for averaging

for (ii = 0; ii < packet_count; ii++) {

int16_t accel_temp[3] = {0, 0, 0}, gyro_temp[3] = {0, 0, 0};

readBytes(MPU6050_ADDRESS, FIFO_R_W, 12, &data[0]); // read data for averaging

accel_temp[0] = (int16_t) (((int16_t)data[0] << 8) | data[1] ) ; // Form signed 16-bit integer for each sample in FIFO

accel_temp[1] = (int16_t) (((int16_t)data[2] << 8) | data[3] ) ;

accel_temp[2] = (int16_t) (((int16_t)data[4] << 8) | data[5] ) ;

gyro_temp[0] = (int16_t) (((int16_t)data[6] << 8) | data[7] ) ;

gyro_temp[1] = (int16_t) (((int16_t)data[8] << 8) | data[9] ) ;

gyro_temp[2] = (int16_t) (((int16_t)data[10] << 8) | data[11]) ;

accel_bias[0] += (int32_t) accel_temp[0]; // Sum individual signed 16-bit biases to get accumulated signed 32-bit biases

accel_bias[1] += (int32_t) accel_temp[1];

accel_bias[2] += (int32_t) accel_temp[2];

gyro_bias[0] += (int32_t) gyro_temp[0];

gyro_bias[1] += (int32_t) gyro_temp[1];

gyro_bias[2] += (int32_t) gyro_temp[2];

}

accel_bias[0] /= (int32_t) packet_count; // Normalize sums to get average count biases

accel_bias[1] /= (int32_t) packet_count;

accel_bias[2] /= (int32_t) packet_count;

gyro_bias[0] /= (int32_t) packet_count;

gyro_bias[1] /= (int32_t) packet_count;

gyro_bias[2] /= (int32_t) packet_count;

if(accel_bias[2] > 0L) {accel_bias[2] -= (int32_t) accelsensitivity;} // Remove gravity from the z-axis accelerometer bias calculation

else {accel_bias[2] += (int32_t) accelsensitivity;}

// Construct the gyro biases for push to the hardware gyro bias registers, which are reset to zero upon device startup

data[0] = (-gyro_bias[0]/4 >> 8) & 0xFF; // Divide by 4 to get 32.9 LSB per deg/s to conform to expected bias input format

data[1] = (-gyro_bias[0]/4) & 0xFF; // Biases are additive, so change sign on calculated average gyro biases

data[2] = (-gyro_bias[1]/4 >> 8) & 0xFF;

data[3] = (-gyro_bias[1]/4) & 0xFF;

data[4] = (-gyro_bias[2]/4 >> 8) & 0xFF;

data[5] = (-gyro_bias[2]/4) & 0xFF;

// Push gyro biases to hardware registers

writeByte(MPU6050_ADDRESS, XG_OFFS_USRH, data[0]);// might not be supported in MPU6050

writeByte(MPU6050_ADDRESS, XG_OFFS_USRL, data[1]);

writeByte(MPU6050_ADDRESS, YG_OFFS_USRH, data[2]);

writeByte(MPU6050_ADDRESS, YG_OFFS_USRL, data[3]);

writeByte(MPU6050_ADDRESS, ZG_OFFS_USRH, data[4]);

writeByte(MPU6050_ADDRESS, ZG_OFFS_USRL, data[5]);

dest1[0] = (float) gyro_bias[0]/(float) gyrosensitivity; // construct gyro bias in deg/s for later manual subtraction

dest1[1] = (float) gyro_bias[1]/(float) gyrosensitivity;

dest1[2] = (float) gyro_bias[2]/(float) gyrosensitivity;

// Construct the accelerometer biases for push to the hardware accelerometer bias registers. These registers contain

// factory trim values which must be added to the calculated accelerometer biases; on boot up these registers will hold

// non-zero values. In addition, bit 0 of the lower byte must be preserved since it is used for temperature

// compensation calculations. Accelerometer bias registers expect bias input as 2048 LSB per g, so that

// the accelerometer biases calculated above must be divided by 8.

int32_t accel_bias_reg[3] = {0, 0, 0}; // A place to hold the factory accelerometer trim biases

readBytes(MPU6050_ADDRESS, XA_OFFSET_H, 2, &data[0]); // Read factory accelerometer trim values

accel_bias_reg[0] = (int16_t) ((int16_t)data[0] << 8) | data[1];

readBytes(MPU6050_ADDRESS, YA_OFFSET_H, 2, &data[0]);

accel_bias_reg[1] = (int16_t) ((int16_t)data[0] << 8) | data[1];

readBytes(MPU6050_ADDRESS, ZA_OFFSET_H, 2, &data[0]);

accel_bias_reg[2] = (int16_t) ((int16_t)data[0] << 8) | data[1];

uint32_t mask = 1uL; // Define mask for temperature compensation bit 0 of lower byte of accelerometer bias registers

uint8_t mask_bit[3] = {0, 0, 0}; // Define array to hold mask bit for each accelerometer bias axis

for(ii = 0; ii < 3; ii++) {

if(accel_bias_reg[ii] & mask) mask_bit[ii] = 0x01; // If temperature compensation bit is set, record that fact in mask_bit

}

// Construct total accelerometer bias, including calculated average accelerometer bias from above

accel_bias_reg[0] -= (accel_bias[0]/8); // Subtract calculated averaged accelerometer bias scaled to 2048 LSB/g (16 g full scale)

accel_bias_reg[1] -= (accel_bias[1]/8);

accel_bias_reg[2] -= (accel_bias[2]/8);

data[0] = (accel_bias_reg[0] >> 8) & 0xFF;

data[1] = (accel_bias_reg[0]) & 0xFF;

data[1] = data[1] | mask_bit[0]; // preserve temperature compensation bit when writing back to accelerometer bias registers

data[2] = (accel_bias_reg[1] >> 8) & 0xFF;

data[3] = (accel_bias_reg[1]) & 0xFF;

data[3] = data[3] | mask_bit[1]; // preserve temperature compensation bit when writing back to accelerometer bias registers

data[4] = (accel_bias_reg[2] >> 8) & 0xFF;

data[5] = (accel_bias_reg[2]) & 0xFF;

data[5] = data[5] | mask_bit[2]; // preserve temperature compensation bit when writing back to accelerometer bias registers

// Push accelerometer biases to hardware registers

writeByte(MPU6050_ADDRESS, XA_OFFSET_H, data[0]); // might not be supported in MPU6050

writeByte(MPU6050_ADDRESS, XA_OFFSET_L_TC, data[1]);

writeByte(MPU6050_ADDRESS, YA_OFFSET_H, data[2]);

writeByte(MPU6050_ADDRESS, YA_OFFSET_L_TC, data[3]);

writeByte(MPU6050_ADDRESS, ZA_OFFSET_H, data[4]);

writeByte(MPU6050_ADDRESS, ZA_OFFSET_L_TC, data[5]);

// Output scaled accelerometer biases for manual subtraction in the main program

dest2[0] = (float)accel_bias[0]/(float)accelsensitivity;

dest2[1] = (float)accel_bias[1]/(float)accelsensitivity;

dest2[2] = (float)accel_bias[2]/(float)accelsensitivity;

}

// Accelerometer and gyroscope self test; check calibration wrt factory settings

void MPU6050SelfTest(float * destination) // Should return percent deviation from factory trim values, +/- 14 or less deviation is a pass

{

uint8_t rawData[4];

uint8_t selfTest[6];

float factoryTrim[6];

// Configure the accelerometer for self-test

writeByte(MPU6050_ADDRESS, ACCEL_CONFIG, 0xF0); // Enable self test on all three axes and set accelerometer range to +/- 8 g

writeByte(MPU6050_ADDRESS, GYRO_CONFIG, 0xE0); // Enable self test on all three axes and set gyro range to +/- 250 degrees/s

delay(250); // Delay a while to let the device execute the self-test

rawData[0] = readByte(MPU6050_ADDRESS, SELF_TEST_X); // X-axis self-test results

rawData[1] = readByte(MPU6050_ADDRESS, SELF_TEST_Y); // Y-axis self-test results

rawData[2] = readByte(MPU6050_ADDRESS, SELF_TEST_Z); // Z-axis self-test results

rawData[3] = readByte(MPU6050_ADDRESS, SELF_TEST_A); // Mixed-axis self-test results

// Extract the acceleration test results first

selfTest[0] = (rawData[0] >> 3) | (rawData[3] & 0x30) >> 4 ; // XA_TEST result is a five-bit unsigned integer

selfTest[1] = (rawData[1] >> 3) | (rawData[3] & 0x0C) >> 2 ; // YA_TEST result is a five-bit unsigned integer

selfTest[2] = (rawData[2] >> 3) | (rawData[3] & 0x03) ; // ZA_TEST result is a five-bit unsigned integer

// Extract the gyration test results first

selfTest[3] = rawData[0] & 0x1F ; // XG_TEST result is a five-bit unsigned integer

selfTest[4] = rawData[1] & 0x1F ; // YG_TEST result is a five-bit unsigned integer

selfTest[5] = rawData[2] & 0x1F ; // ZG_TEST result is a five-bit unsigned integer

// Process results to allow final comparison with factory set values

factoryTrim[0] = (4096.0*0.34)*(pow( (0.92/0.34) , (((float)selfTest[0] - 1.0)/30.0))); // FT[Xa] factory trim calculation

factoryTrim[1] = (4096.0*0.34)*(pow( (0.92/0.34) , (((float)selfTest[1] - 1.0)/30.0))); // FT[Ya] factory trim calculation

factoryTrim[2] = (4096.0*0.34)*(pow( (0.92/0.34) , (((float)selfTest[2] - 1.0)/30.0))); // FT[Za] factory trim calculation

factoryTrim[3] = ( 25.0*131.0)*(pow( 1.046 , ((float)selfTest[3] - 1.0) )); // FT[Xg] factory trim calculation

factoryTrim[4] = (-25.0*131.0)*(pow( 1.046 , ((float)selfTest[4] - 1.0) )); // FT[Yg] factory trim calculation

factoryTrim[5] = ( 25.0*131.0)*(pow( 1.046 , ((float)selfTest[5] - 1.0) )); // FT[Zg] factory trim calculation

// Output self-test results and factory trim calculation if desired

// Serial.println(selfTest[0]); Serial.println(selfTest[1]); Serial.println(selfTest[2]);

// Serial.println(selfTest[3]); Serial.println(selfTest[4]); Serial.println(selfTest[5]);

// Serial.println(factoryTrim[0]); Serial.println(factoryTrim[1]); Serial.println(factoryTrim[2]);

// Serial.println(factoryTrim[3]); Serial.println(factoryTrim[4]); Serial.println(factoryTrim[5]);

// Report results as a ratio of (STR - FT)/FT; the change from Factory Trim of the Self-Test Response

// To get to percent, must multiply by 100 and subtract result from 100

for (int i = 0; i < 6; i++) {

destination[i] = 100.0 + 100.0*((float)selfTest[i] - factoryTrim[i])/factoryTrim[i]; // Report percent differences

}

}

void writeByte(uint8_t address, uint8_t subAddress, uint8_t data)

{

Wire1.beginTransmission(address); // Initialize the Tx buffer

Wire1.write(subAddress); // Put slave register address in Tx buffer

Wire1.write(data); // Put data in Tx buffer

Wire1.endTransmission(); // Send the Tx buffer

}

uint8_t readByte(uint8_t address, uint8_t subAddress)

{

uint8_t data; // `data` will store the register data

Wire1.beginTransmission(address); // Initialize the Tx buffer

Wire1.write(subAddress); // Put slave register address in Tx buffer

Wire1.endTransmission(false); // Send the Tx buffer, but send a restart to keep connection alive

Wire1.requestFrom(address, (uint8_t) 1); // Read one byte from slave register address

data = Wire1.read(); // Fill Rx buffer with result

return data; // Return data read from slave register

}

void readBytes(uint8_t address, uint8_t subAddress, uint8_t count, uint8_t * dest)

{

Wire1.beginTransmission(address); // Initialize the Tx buffer

Wire1.write(subAddress); // Put slave register address in Tx buffer

Wire1.endTransmission(false); // Send the Tx buffer, but send a restart to keep connection alive

uint8_t i = 0;

Wire1.requestFrom(address, count); // Read bytes from slave register address

while (Wire1.available()) {

dest[i++] = Wire1.read(); } // Put read results in the Rx buffer

}

void MadgwickQuaternionUpdate(float ax, float ay, float az, float gx, float gy, float gz)

{

float q1 = q[0], q2 = q[1], q3 = q[2], q4 = q[3]; // short name local variable for readability

float norm; // vector norm

float f1, f2, f3; // objetive funcyion elements

float J_11or24, J_12or23, J_13or22, J_14or21, J_32, J_33; // objective function Jacobian elements

float qDot1, qDot2, qDot3, qDot4;

float hatDot1, hatDot2, hatDot3, hatDot4;

float gerrx, gerry, gerrz, gbiasx, gbiasy, gbiasz; // gyro bias error

// Auxiliary variables to avoid repeated arithmetic

float _halfq1 = 0.5f * q1;

float _halfq2 = 0.5f * q2;

float _halfq3 = 0.5f * q3;

float _halfq4 = 0.5f * q4;

float _2q1 = 2.0f * q1;

float _2q2 = 2.0f * q2;

float _2q3 = 2.0f * q3;

float _2q4 = 2.0f * q4;

float _2q1q3 = 2.0f * q1 * q3;

float _2q3q4 = 2.0f * q3 * q4;

// Normalise accelerometer measurement

norm = sqrt(ax * ax + ay * ay + az * az);

if (norm == 0.0f) return; // handle NaN

norm = 1.0f/norm;

ax *= norm;

ay *= norm;

az *= norm;

// Compute the objective function and Jacobian

f1 = _2q2 * q4 - _2q1 * q3 - ax;

f2 = _2q1 * q2 + _2q3 * q4 - ay;

f3 = 1.0f - _2q2 * q2 - _2q3 * q3 - az;

J_11or24 = _2q3;

J_12or23 = _2q4;

J_13or22 = _2q1;

J_14or21 = _2q2;

J_32 = 2.0f * J_14or21;

J_33 = 2.0f * J_11or24;

// Compute the gradient (matrix multiplication)

hatDot1 = J_14or21 * f2 - J_11or24 * f1;

hatDot2 = J_12or23 * f1 + J_13or22 * f2 - J_32 * f3;

hatDot3 = J_12or23 * f2 - J_33 *f3 - J_13or22 * f1;

hatDot4 = J_14or21 * f1 + J_11or24 * f2;

// Normalize the gradient

norm = sqrt(hatDot1 * hatDot1 + hatDot2 * hatDot2 + hatDot3 * hatDot3 + hatDot4 * hatDot4);

hatDot1 /= norm;

hatDot2 /= norm;

hatDot3 /= norm;

hatDot4 /= norm;

// Compute estimated gyroscope biases

gerrx = _2q1 * hatDot2 - _2q2 * hatDot1 - _2q3 * hatDot4 + _2q4 * hatDot3;

gerry = _2q1 * hatDot3 + _2q2 * hatDot4 - _2q3 * hatDot1 - _2q4 * hatDot2;

gerrz = _2q1 * hatDot4 - _2q2 * hatDot3 + _2q3 * hatDot2 - _2q4 * hatDot1;

// Compute and remove gyroscope biases

gbiasx += gerrx * deltat * zeta;

gbiasy += gerry * deltat * zeta;

gbiasz += gerrz * deltat * zeta;

gx -= gbiasx;

gy -= gbiasy;

gz -= gbiasz;

// Compute the quaternion derivative

qDot1 = -_halfq2 * gx - _halfq3 * gy - _halfq4 * gz;

qDot2 = _halfq1 * gx + _halfq3 * gz - _halfq4 * gy;

qDot3 = _halfq1 * gy - _halfq2 * gz + _halfq4 * gx;

qDot4 = _halfq1 * gz + _halfq2 * gy - _halfq3 * gx;

// Compute then integrate estimated quaternion derivative

q1 += (qDot1 -(beta * hatDot1)) * deltat;

q2 += (qDot2 -(beta * hatDot2)) * deltat;

q3 += (qDot3 -(beta * hatDot3)) * deltat;

q4 += (qDot4 -(beta * hatDot4)) * deltat;

// Normalize the quaternion

norm = sqrt(q1 * q1 + q2 * q2 + q3 * q3 + q4 * q4); // normalise quaternion

norm = 1.0f/norm;

q[0] = q1 * norm;

q[1] = q2 * norm;

q[2] = q3 * norm;

q[3] = q4 * norm;

}