Jonathanese

Member

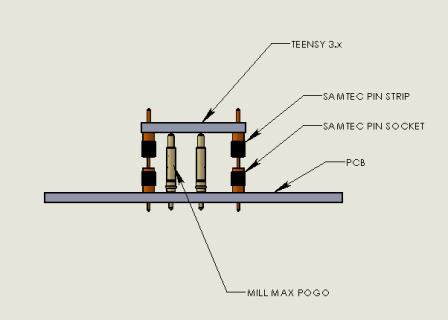

I have a couple projects in the future that may involve using pads at the bottom of the Teensy 3.6 board, but I don't want to have the contacts soldered as that would be messy and require extra tools.

I've been looking at some spring contacts to touch the pads and wasn't sure if you guys had a particular part you recommend for this application. Basically the idea would be to add and remove the teensy without having to solder/desolder anything (after the board is constructed, of course)

Something like these:

https://www.digikey.com/product-detail/en/mill-max-manufacturing-corp/0932-0-15-20-77-14-11-0/ED90345-ND/1873758

I've been looking at some spring contacts to touch the pads and wasn't sure if you guys had a particular part you recommend for this application. Basically the idea would be to add and remove the teensy without having to solder/desolder anything (after the board is constructed, of course)

Something like these:

https://www.digikey.com/product-detail/en/mill-max-manufacturing-corp/0932-0-15-20-77-14-11-0/ED90345-ND/1873758