Hey back again wanting to start another project and foresee a couple of obstacles I thought I might run by you guys to get some feedback how to work around. I do a lot of RC Plane and Drone project work and I want to build a Battery Monitor to be able to read as many as 6 LiPo cells in series. But for the life of me having a brain fart on how to do it. I see two problems.

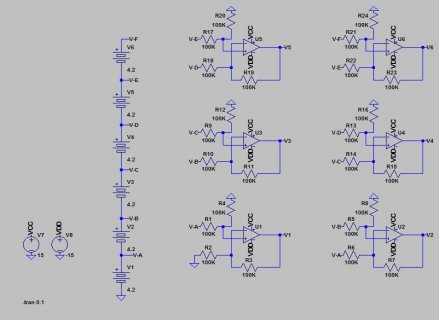

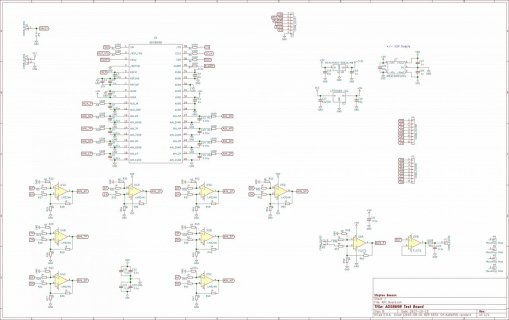

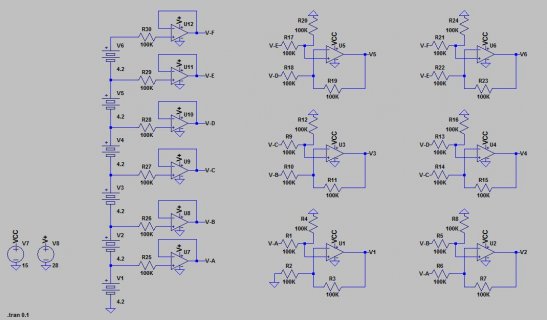

1. RC LiPo batteries come hard wired in series from 2S to 6S and equipped with a Balance Plug to allow direct access to individual cell voltages so they can be balanced by external circuitry. The A/D converter is referenced to a common point in the Teensy and I am clueless how I can decouple the the common rail so I can measure voltages of up to 6 cells wired in series without shorting the cells out. I know it can be done, but dang if I can figure it out.

2. Cell voltages will range from a low of 3 volts up to 4.3 volts which is outside the range of Teensy 3.3 volt limit. I need good accuracy. One thing I thought about is a Resistor Divider across each cell to scale down 4.3 volts to 3.3 volts but that adds error even if I were to use 1% resistors. Other thought and not sure it could be done is use an external 5 volt ADC somehow to feed to a Teensy. I would use an Ardiuno but the A/D resolution is too low.

I need a fair bit of accuracy as one thing I want this gizmo to do is measure each of the cells internal resistance with a LSB of .0001 Ohms. To do that I would use a Delta Voltage/Current method as it is the most accurate means to do that. Example apply say apply a Low Current Load of say 100 ma to the battery, read each cell voltage, and record the voltages. Then apply a 10-amp load and record cell voltages as low current. From there derive Delta Voltage/Current and apply Ohm's Law of R = V/I.

So can you help me please with some ideas? All comments welcome.

THX

Dereck

1. RC LiPo batteries come hard wired in series from 2S to 6S and equipped with a Balance Plug to allow direct access to individual cell voltages so they can be balanced by external circuitry. The A/D converter is referenced to a common point in the Teensy and I am clueless how I can decouple the the common rail so I can measure voltages of up to 6 cells wired in series without shorting the cells out. I know it can be done, but dang if I can figure it out.

2. Cell voltages will range from a low of 3 volts up to 4.3 volts which is outside the range of Teensy 3.3 volt limit. I need good accuracy. One thing I thought about is a Resistor Divider across each cell to scale down 4.3 volts to 3.3 volts but that adds error even if I were to use 1% resistors. Other thought and not sure it could be done is use an external 5 volt ADC somehow to feed to a Teensy. I would use an Ardiuno but the A/D resolution is too low.

I need a fair bit of accuracy as one thing I want this gizmo to do is measure each of the cells internal resistance with a LSB of .0001 Ohms. To do that I would use a Delta Voltage/Current method as it is the most accurate means to do that. Example apply say apply a Low Current Load of say 100 ma to the battery, read each cell voltage, and record the voltages. Then apply a 10-amp load and record cell voltages as low current. From there derive Delta Voltage/Current and apply Ohm's Law of R = V/I.

So can you help me please with some ideas? All comments welcome.

THX

Dereck