AdmiralCrunch

Well-known member

Hi

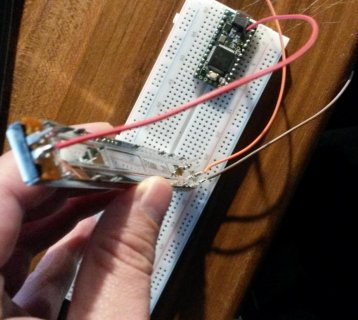

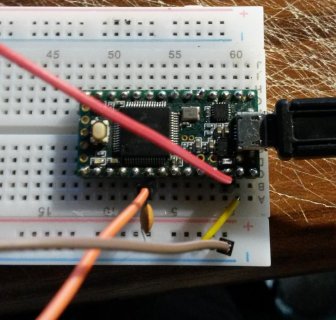

I have some of those APLS 10K Dual slide potentiometer, I attached one directly and I read it like

.. and it seems to work, but the "resolution" is somehow .. strange .. where 0 should be, there is a 100 (+/- some noise) .. and when I move the slider a little just a little, there is immediately 1023 .. how can this be? has someone experienced something like that ?

I have some of those APLS 10K Dual slide potentiometer, I attached one directly and I read it like

Code:

const int analogInPin = A4;

int sensorValue = 0;

void setup() {

Serial.begin(38400);

}

void loop() {

sensorValue = analogRead(analogInPin);

Serial.println(sensorValue);

}.. and it seems to work, but the "resolution" is somehow .. strange .. where 0 should be, there is a 100 (+/- some noise) .. and when I move the slider a little just a little, there is immediately 1023 .. how can this be? has someone experienced something like that ?