You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Teensy 4.0 Breakout Kit

- Thread starter loglow

- Start date

Nice the Flex Cable is symmetric, also that it terminates in the connector and not soldered on both ends.

For the basic breakout kit, the flex cable would actually be intended to be soldered on both ends. The connector part would be included with a separate socket kit. I don't think there's any reason to use a connector when the Teensy itself isn't removable.

CR1220's are nicely smaller, assuming those won't ship ( I have a pack ) - any other parts that won't be included?

I'm leaning toward including a CR1220 in the kit since they're small and cheap. Everything listed above (plus some generic pin headers) will be included in beta kits, and probably also in kits moving forward after that too, except for the flex connector which would be moved to a socket kit (with expensive custom Samtec headers).

No gratuitous LED for Power - which actually was telling with what resulted in the 'white wire' edit during Beta. But no open space near 3V3 - or to drop pin or extra parts on a very full PCB.

Not sure what you meant here. Were you wishing that there was a power LED, or were you happy that one wasn't added to the breakout?

@loglow I would recommend thicker traces for the power and ground rails along the tops/bottoms (and from there to the original source of those signals.)

Perhaps if they're fed by the Teensy itself, they already have limited current supply capacity, though?

The top/bottom rails aren't actually connected at all to the rest of the breakout board. You have to connect them yourself if you want to use them, because they're v-scored so they can be snapped off if you don't need them or if you want the breakout to fit on a breadboard. It'd be easier to make the traces a bit thicker though. Right now they're 10 mil, but I think I'll change them to 20 mil for future runs. There's no soldermask on the bottom of them so you can easily separate them into different sections (with a razor blade) if need-be.

defragster

Senior Member+

Cool the spacing allows solder with/without connector - indeed once the T4 is committed ideally it stays.

Not sure how you ship - but the world is scared of lithium - Paul excluded his 2032's. Though Amazon just shipped me a pack - and labelled as such.

An LED like on the PJRC board would be pretty and fun - perhaps even useful for some - but I see no room for it easily to justify adding parts or effort to find a place for it.

So just throwing it out there in case it was something you saw value in it. With the On/Off ability Paul included it for watching the 3V3 line drop and rise on Off and On.

Not sure how you ship - but the world is scared of lithium - Paul excluded his 2032's. Though Amazon just shipped me a pack - and labelled as such.

...Not sure what you meant here. Were you wishing that there was a power LED, or were you happy that one wasn't added to the breakout?

...

An LED like on the PJRC board would be pretty and fun - perhaps even useful for some - but I see no room for it easily to justify adding parts or effort to find a place for it.

So just throwing it out there in case it was something you saw value in it. With the On/Off ability Paul included it for watching the 3V3 line drop and rise on Off and On.

Alex Stahl

Member

I am very keen to help test this board. Have two T4's and I don't mind paying costs... I'm on a tight schedule to try upgrading to T4 in an active project and this board looks great. Let me know and thanks!

I am very keen to help test this board. Have two T4's and I don't mind paying costs... I'm on a tight schedule to try upgrading to T4 in an active project and this board looks great. Let me know and thanks!

Cool, just sent you a PM.

wwatson

Well-known member

@loglow

I have been using your t36 breakout board for my t36 system for quite a while now. It gave me the utility to develop MSC and a RA8876 10.1" display from Buy Display.

Cannot wait for the T4 version. Will there be an assembled version available with the T4? To shakey to assemble it myself.

Thanks

I have been using your t36 breakout board for my t36 system for quite a while now. It gave me the utility to develop MSC and a RA8876 10.1" display from Buy Display.

Cannot wait for the T4 version. Will there be an assembled version available with the T4? To shakey to assemble it myself.

Thanks

Hey loglow! you mind if I get in on this also?

PM sent.

Will there be an assembled version available with the T4?

Yes, there certainly will be a pre-assembled option!

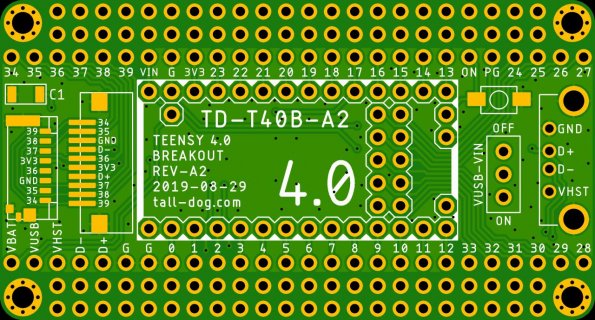

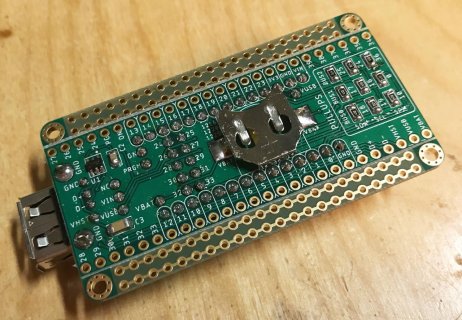

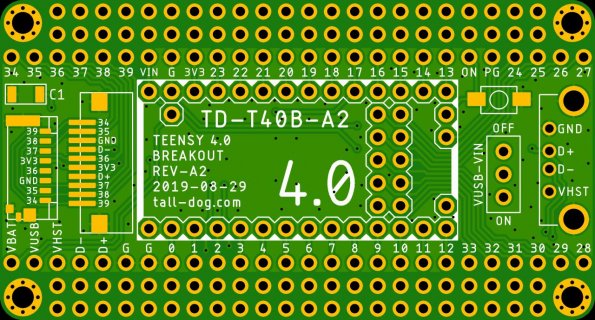

Here's an update!

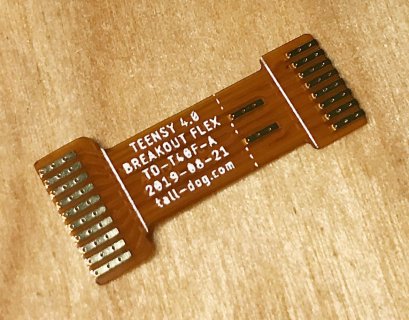

I got the first batch of test boards back. The flex cables look good, and seem to work fine, both in terms of direct soldering, or when used with a connector socket. They are 0.26 mm thick, which was the closest to 0.3 mm (the recommended thickness for the sockets) that I could reasonably make them. I didn't want to use stiffeners on either end since I wanted them to be able to be soldered directly as well.

The breakout boards have some mistakes. The component numbers (U1, C1, C2, etc.) got messed up on most of the boards when I panelized them, but that's an easy fix. The big issue is that I got the SD socket backwards. Since I haven't used these very narrow sockets before, I apparently didn't assume the correct orientation. Whoops. I've re-positioned and re-routed this component. It's a bit tight, but I still managed to stick to >6 mil traces/spacing. New revision below:

For the above reasons, I'm not going to send out these boards to beta testers yet. I'll wait for the next (fixed) batch to arrive in a week or so.

I also did some assembly testing with these boards, and things look okay so far. The ~1.0 mm pitch components do require a little more care when soldering, but it's not difficult to get consistent results. Likewise with the other SMD components. I'd say the difficulty of assembly (in terms of soldering) has certainly increased, but not by an unreasonable amount. I know that SMD is intimidating to some folks, but with a good iron and some flux it's not too bad. I was afraid that some of the components would require hot-air or oven reflow (with solder paste and a stencil) but that's fortunately not the case. The SD socket is the most difficult, because of its little overhang, but I was still able to solder it without too much trouble (with some good light). It also turns out that the generic Chinese equivalent of this part seems to be ever-so-slightly easier to solder than the Amphenol one.

Here are a bunch of photos:

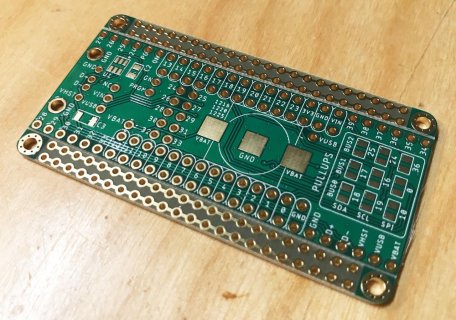

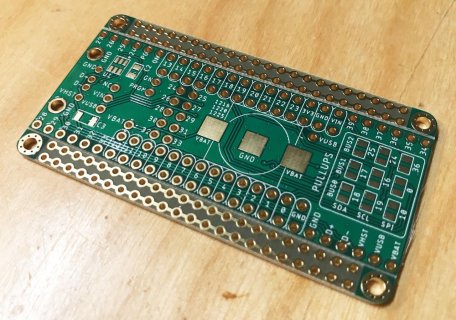

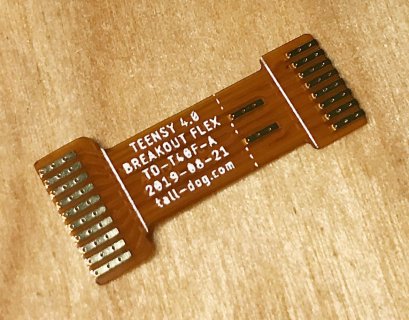

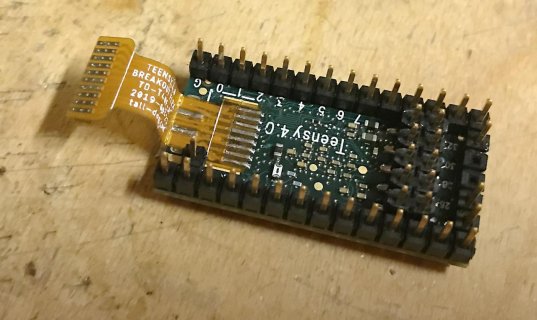

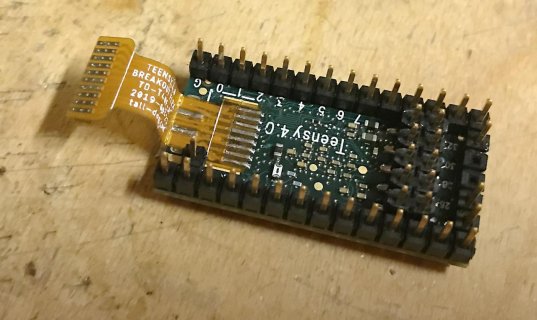

Top and bottom of bare board and flex cable:

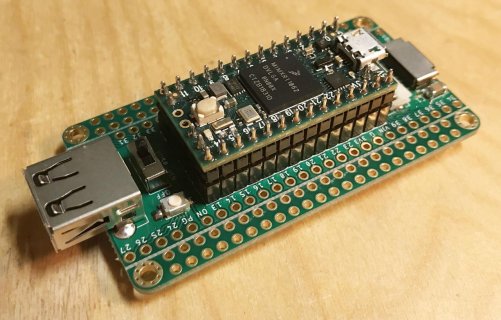

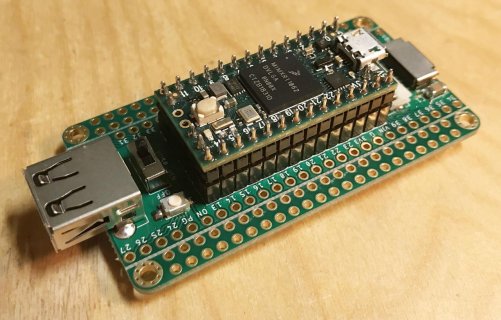

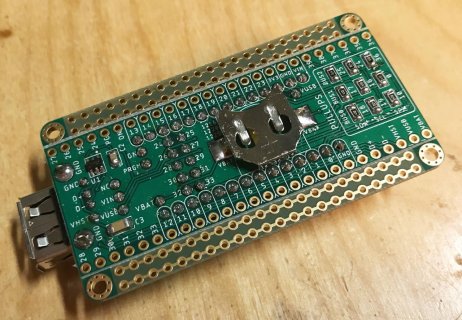

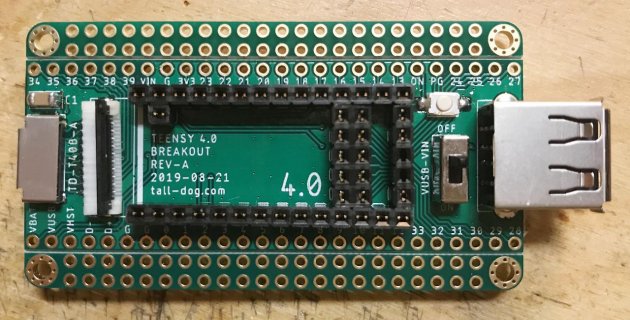

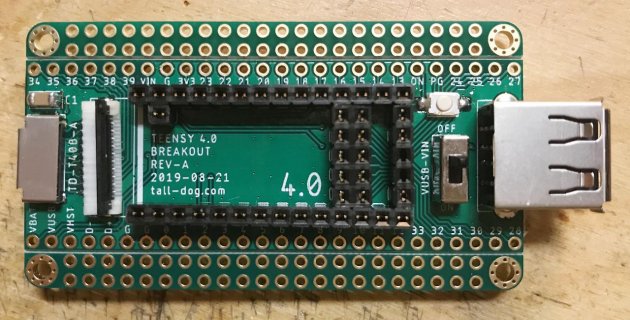

Top and bottom of finished (socketed) assembly:

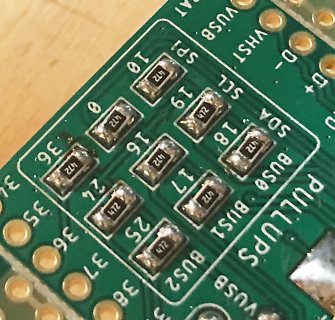

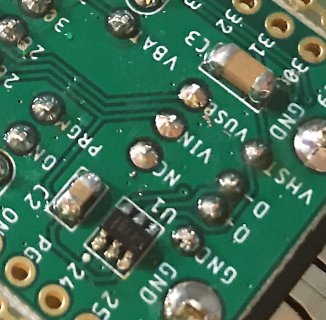

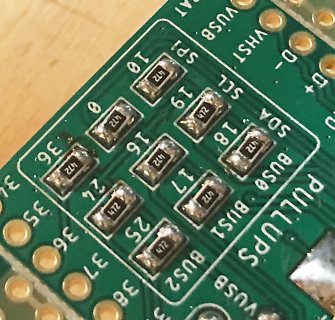

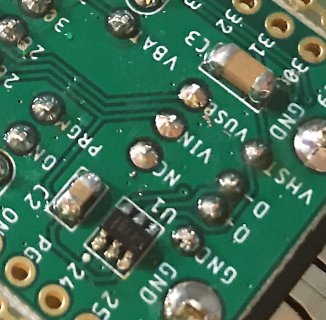

Closeup of soldering the flex cable directly to the breakout, pullup resistors (0805 components), and USB host components:

More photos in the next post...

I got the first batch of test boards back. The flex cables look good, and seem to work fine, both in terms of direct soldering, or when used with a connector socket. They are 0.26 mm thick, which was the closest to 0.3 mm (the recommended thickness for the sockets) that I could reasonably make them. I didn't want to use stiffeners on either end since I wanted them to be able to be soldered directly as well.

The breakout boards have some mistakes. The component numbers (U1, C1, C2, etc.) got messed up on most of the boards when I panelized them, but that's an easy fix. The big issue is that I got the SD socket backwards. Since I haven't used these very narrow sockets before, I apparently didn't assume the correct orientation. Whoops. I've re-positioned and re-routed this component. It's a bit tight, but I still managed to stick to >6 mil traces/spacing. New revision below:

For the above reasons, I'm not going to send out these boards to beta testers yet. I'll wait for the next (fixed) batch to arrive in a week or so.

I also did some assembly testing with these boards, and things look okay so far. The ~1.0 mm pitch components do require a little more care when soldering, but it's not difficult to get consistent results. Likewise with the other SMD components. I'd say the difficulty of assembly (in terms of soldering) has certainly increased, but not by an unreasonable amount. I know that SMD is intimidating to some folks, but with a good iron and some flux it's not too bad. I was afraid that some of the components would require hot-air or oven reflow (with solder paste and a stencil) but that's fortunately not the case. The SD socket is the most difficult, because of its little overhang, but I was still able to solder it without too much trouble (with some good light). It also turns out that the generic Chinese equivalent of this part seems to be ever-so-slightly easier to solder than the Amphenol one.

Here are a bunch of photos:

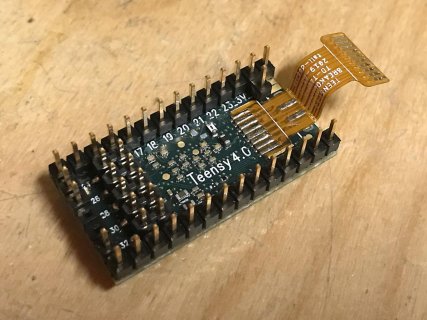

Top and bottom of bare board and flex cable:

Top and bottom of finished (socketed) assembly:

Closeup of soldering the flex cable directly to the breakout, pullup resistors (0805 components), and USB host components:

More photos in the next post...

The assembled (socketed) breakout without Teensy:

The assembly showing flex cable and socket (the locking tab is flipped up in the left photo):

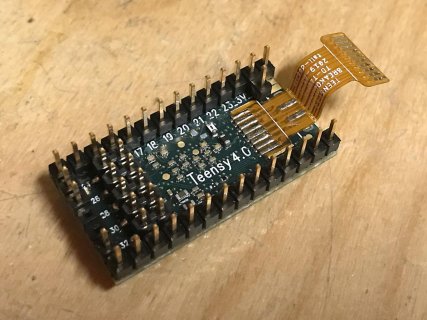

The Teensy by itself with headers and flex cable attached:

Some notes:

Dan

The assembly showing flex cable and socket (the locking tab is flipped up in the left photo):

The Teensy by itself with headers and flex cable attached:

Some notes:

- The battery is tricky to remove without trimming down the through-hole pin tails that are right in front of its opening.

- The flex cable still has a tiny bit of "slip" when the connector tab is locked, but it seems like the socket's contacts grab onto the tiny through-holes, preventing it from being pulled out. Lucky coincidence.

- The headers on the short edge of the Teensy are just 5-pin strips with the pins in positions 2 and 3 removed.

- I might use a 4-pin (2x2) header with one pin removed for the corner with VUSB, instead of a 1-pin header (which is less stable during assembly).

Dan

mjs513

Senior Member+

@loglow

Impressive board - its looking real good. What headers are you using for the T4 - looks like machine headers?

Just as a noted just started with soldering SMD components - a little more challenging than through holes but I found a couple of good videos on youtube that helped have to dig them up - maybe would help folks never did it before. Used a solder pen and thin solder from Kester and it works great - just need a little patience and for us older folks a magnifier with LED lights helped a lot

Only thing that seems to be a little challenging is the flexcable connectors and soldering - that should be interesting.

Oh one final thing - very very rarely did I ever have a board perfect with the first batch.

Mike

EDIT: Forgot - those photos are great - definitely good for assembling the board.

Impressive board - its looking real good. What headers are you using for the T4 - looks like machine headers?

Just as a noted just started with soldering SMD components - a little more challenging than through holes but I found a couple of good videos on youtube that helped have to dig them up - maybe would help folks never did it before. Used a solder pen and thin solder from Kester and it works great - just need a little patience and for us older folks a magnifier with LED lights helped a lot

Only thing that seems to be a little challenging is the flexcable connectors and soldering - that should be interesting.

Oh one final thing - very very rarely did I ever have a board perfect with the first batch.

Mike

EDIT: Forgot - those photos are great - definitely good for assembling the board.

What headers are you using for the T4 - looks like machine headers?

The basic kit will include totally generic tin-plated square-post header strips.

The ones pictured here, which will be included in the optional Socket Kit, are Samtec low-profile socket strips (SLW-1**-01-F-S and -D) and custom height square-post male headers (MTSW-1**-07-F-S-170 and TSM-1**-04-F-DV).

Only thing that seems to be a little challenging is the flexcable connectors and soldering - that should be interesting.

It's not bad: Melt some solder onto the pads to start with. Tape things down, verify good alignment. Heat each pin until the solder below melts up through the tiny holes. Apply some more flux, and then reflow each pin, adding just a bit more solder.

very very rarely did I ever have a board perfect with the first batch.

They never are, no matter how many times I check everything beforehand!

those photos are great - definitely good for assembling the board.

Thanks. I think the assembly instructions for these kits will (for the first time) include step-by-step photos.

defragster

Senior Member+

Agree with @mjs513's post - Impressive ... and good answers. Those low profile sockets look nice! Full height just seem wrong on Teensy.

Bummer on the SD pin/socket direction surprise. Great the Flex boards work!

Trimming pin tips is easy enough for battery fitting as it does. If no other changes those "no SD" boards would be good for Beta test solder practice and non-SD ab/use.

Bummer on the SD pin/socket direction surprise. Great the Flex boards work!

Trimming pin tips is easy enough for battery fitting as it does. If no other changes those "no SD" boards would be good for Beta test solder practice and non-SD ab/use.

KurtE

Senior Member+

I second/third @mjs513/@defragster - nice looking board.

I also like the fact that you bring out the SD card pins to the outside. So for those who want more pins, and can live without SD (or 4 bit SD), they can use those six IO pins for something else. Including a full SPI port (with CS), so you could still run an external SDCard off of it using SPI2...

I also like the fact that you bring out the SD card pins to the outside. So for those who want more pins, and can live without SD (or 4 bit SD), they can use those six IO pins for something else. Including a full SPI port (with CS), so you could still run an external SDCard off of it using SPI2...

Thanks for the feedback everyone!

I don't think I'm going to send out any of the first run (mistake) boards, just because I don't want to cause any unnecessary confusion (for myself or anyone else).

I'm still figuring out the final price for the base breakout kit. I think it'll end up being in the $16 to $22 USD range, depending on the bulk prices of the various components and the compatibility/quality of any generic alternates.

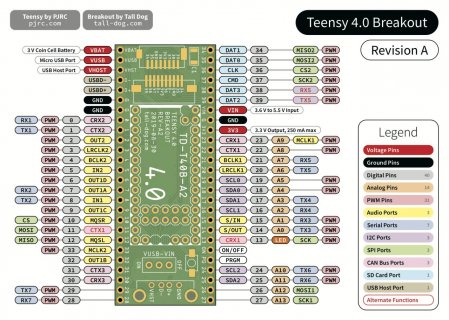

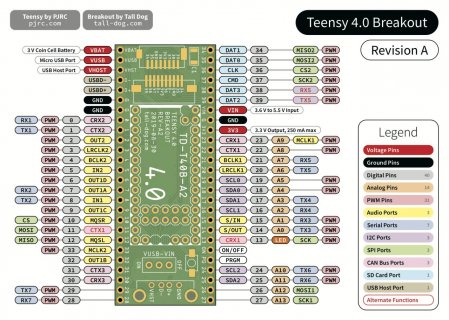

Pinout Card

Here's a draft of the PDF pinout card: View attachment Card.pdf

Or here's a rasterized (lower quality) version:

Hopefully no mistakes!? If anyone feels like proofing this, please let me know.

This will accompany the kit as a printed 5" x 7" card.

Socket Kit

Provisional kit contents:

I don't think I'm going to send out any of the first run (mistake) boards, just because I don't want to cause any unnecessary confusion (for myself or anyone else).

I'm still figuring out the final price for the base breakout kit. I think it'll end up being in the $16 to $22 USD range, depending on the bulk prices of the various components and the compatibility/quality of any generic alternates.

Pinout Card

Here's a draft of the PDF pinout card: View attachment Card.pdf

Or here's a rasterized (lower quality) version:

Hopefully no mistakes!? If anyone feels like proofing this, please let me know.

This will accompany the kit as a printed 5" x 7" card.

Socket Kit

Provisional kit contents:

- 1x Wurth 686110148922 (or equivalent)

- 1x Samtec SLW-114-01-F-S

- 1x Samtec SLW-112-01-F-S

- 1x Samtec SLW-105-01-F-S

- 1x Samtec SLW-102-01-F-D

- 1x Samtec SLW-105-01-F-D

- 1x Samtec MTSW-114-07-F-S-170

- 1x Samtec MTSW-112-07-F-S-170

- 1x Samtec MTSW-105-07-F-S-170

- 1x Samtec MTSW-102-07-F-D-170

- 1x Samtec TSM-105-04-F-DV

defragster

Senior Member+

Took a bit of a glance at the card and what I followed checks out on first look. All the groups match what I saw on PCB and account for what is presented on the T4 as I saw it. Certainly makes clear what is what and with the T4 aligned what comes from where in general both as far as the card and the PCB silkscreen and layout. Is the back filled with anything?

What SPI function is on PIN #0? It has a bottom PullUp

KurtE has a better pin grasp and list.

What SPI function is on PIN #0? It has a bottom PullUp

KurtE has a better pin grasp and list.

Last edited:

KurtE

Senior Member+

@loglow @defragster - Yes pins 0 and 1 have SPI1 functionality...

Here is from my XLS doc:

Sorry the columns probably won't line up here, but...

Here is from my XLS doc:

Code:

[COLOR="#0000FF"]Pin Name GPIO Serial I2C SPI PWM CAN Audio XBAR FlexIO Analog SD[/COLOR]

0 AD_B0_03 1.3 Serial1(6) RX [COLOR="#FF0000"]SPI1(3) CS[/COLOR]0 PWM1_X1 2_RX IO-17

1 AD_B0_02 1.2 Serial1(6) TX [COLOR="#FF0000"]SPI1(3) MISO[/COLOR] PWM1_X0 2_TX IO-16

2 EMC_04 4.4 PWM4_A2 2:TX_DATA IO-06 1:4

3 EMC_05 4.5 PWM4_B2 2:TX_SYNC IO-07 1:5

4 EMC_06 4.6 PWM2_A0 2:TX_BCLK IO-08 1:6

5 EMC_08 4.8 PWM2_A1 2:RX_DATA IO-17 1:8

6 B0_10 2.10 PWM2_A2 QT4_1 1:TX3_RX1 2:10

7 B1_01 2.17 Serial2(4) RX PWM1_B3 1:TX_DATA IO-15 2:17, 3:17

8 B1_00 2.16 Serial2(4) TX PWM1_A3 1:RX_DATA IO-14 2:16, 3:16

9 B0_11 2.11 PWM2_B2 QT4_2 1:TX2_RX2 2:11

10 B0_00 2.0 SPI(4) CS0 QT1_0 MQS_RIGHT 2:0

11 B0_02 2.2 SPI(4) MOSI QT1_2 1_TX 2:2

12 B0_01 2.1 SPI(4) MISO QT1_1 MQS_LEFT 2:1

13 B0_03 2.3 SPI(4) SCK QT2_0 1_RX 2:3

14/A0 AD_B1_02 1.18 Serial3(2) TX QT3_2 SPDIF_OUT 3:2 A1:7, A2:7

15/A1 AD_B1_03 1.19 Serial3(2) RX QT3_3 SPDIF_IN 3:3 A1:8, A2:8

16/A2 AD_B1_07 1.23 Serial4(3) RX Wire1(3) SCL SPDIF_EXTCLK 3:7 A1:12, A2:12

17/A3 AD_B1_06 1.22 Serial4(3) TX Wire1(3) SDA SPDIF_LOCK 3:6 A1:11, A2:11

18/A4 AD_B1_01 1.17 Serial3(2) CTS Wire(1) SDA QT3_1 3:1 A1:6, A2:6

19/A5 AD_B1_00 1.16 Wire(1) SCL QT3_0 3:0 A1:5, A2:5

20/A6 AD_B1_10 1.26 Serial5(8) TX 1:RX_SYNC 3:10 A1:15, A2:15

21/A7 AD_B1_11 1.27 Serial5(8) RX 1:RX_BCLK 3:11 A1:0, A2:0

22/A8 AD_B1_08 1.24 PWM4_A0 1_TX 3:8 A1:13, A2:13

23/A9 AD_B1_09 1.25 PWM4_A1 1_RX 1:MCLK 3:9 A1:14, A2:14

--- ---- ---- ------ --- --- --- --- ---- ---- ----- ------

24/A10 AD_B0_12 1.12 Serial6(1) TX Wire2(4) SCL PWM1_X2 A1:1

25/A11 AD_B0_13 1.13 Serial6(1) RX Wire2(4) SDA PWM1_X3 GPT1_CLK A1:2

26/A12 AD_B1_14 1.30 SPI1(3) MOSI 1:TX_BCLK 3:14 A2:3

27/A13 AD_B1_15 1.31 SPI1(3) SCK 1:TX_SYNC 3:15 A2:4

28 EMC_32 3.18 Serial7(7) RX PWM3_B1

29 EMC_31 4.31 Serial7(7) TX SPI2(1) CS1 PWM3_A1

30 EMC_37 3.23 GPT1_3 3_RX 3:MCLK IO-23

31 EMC_36 3.22 GPT1_2 3_TX 3:TX_DATA IO-22

32 B0_12 2.12 1:TX1_RX3 IO-10 2:12

33 EMC_07 4.7 PWM2_B0 2:MCLK IO-09 1:7

34 SD_B0_03 2.15 Serial5(8) RTS SPI2(1) MISO PWM1_B1 IO-07 DATA1

35 SD_B0_02 3.14 Serial5(8) CTS SPI2(1) MOSI PWM1_A1 IO-06 DATA0

36 SD_B0_01 3.13 Wire1(3) SDA SPI2(1) CS0 PWM1_B0 IO-05 CLK

37 SD_B0_00 3.12 Wire1(3) SCL SPI2(1) SCK PWM1_A0 IO-04 CMD

38 SD_B0_05 3.17 Serial5(8) RX SPI2(1) B_DQS PWM1_B2 IO-09 DATA3

39 SD_B0_04 3.16 Serial5(8) TX SPI2(1) B_SSO_B PWM1_A2 IO-08 DATA2MichaelMeissner

Senior Member+

Pin 0 is also CS1, and Pin 1 is MISO1. Paul left these out of the original printing for the cards that came with the Teensy 4.0.

loglow, i'm wondering if your flex will fit tight in the 609-1788-1-ND connector used on the beta test setups? that connector is a pressure fit, it looks like, whereas yours has a lock tab which you mention helps grip it. i don't want to solder flex to teensy until i decide to dedicate a teensy to the breakout. another thing i wonder about is the usb-a anchor pins being that close to the edge of the board. i've never had a board of any type with usb that far forward on the edge and it seems to me it might have too much stress crack potential. maybe not, maybe just lack of experience using a placement like that. ok, thanks

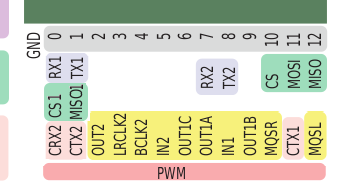

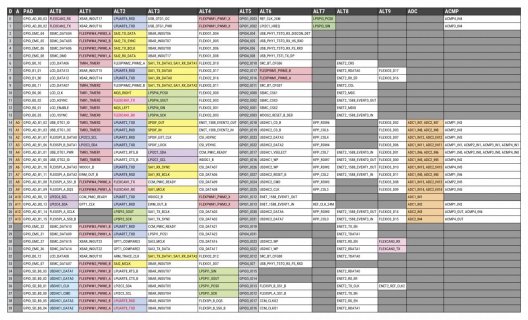

So, I cross-referenced my pinout card with the data from @KurtE, and this is the result:

Light red background = Not currently included on pinout card

Red text = Alternate pin for this function

Green background = Possibly missing information

Not Included (should any of this info be added?):

Light red background = Not currently included on pinout card

Red text = Alternate pin for this function

Green background = Possibly missing information

Not Included (should any of this info be added?):

- Pin Names (eg. AD_B0_03, AD_B0_02, etc.)

- GPIO (eg. 1.3, 1.2, etc.)

- PWM Names (eg. PWM1_X1, PWM1_X0, etc.) - Could replace the existing "PWM" labels with info like "1:X1" if useful?

- XBAR (eg. IO-17, IO-16, etc.)

- FlexIO (eg. 1:4, 1:5, etc.)

- Analog Info (eg. A1:7, A1:8, etc.)

- Serial, Serial3(2) CTS (pin 18)

- Serial, Serial5(8) RTS (pin 34)

- Serial, Serial5(8) CTS (pin 35)

- I2C, Wire1(3) SDA (pin 36) - Is this an alternate to SDA1 (pin 17)?

- I2C, Wire1(3) SCL (pin 37) - Is this an alternate to SCL1 (pin 16)?

- SPI, SPI1(3) CS0 (pin 0) - Confirmed, this will be added as CS1

- SPI, SPI1(3) MISO (pin 1) - Confirmed, this will be added as MISO1

- SPI, SPI2(1) CS1 (pin 29)

- SPI, SPI2(1) B_DQS (pin 38)

- SPI, SPI2(1) B_SSO_B (pin 39)

- PWM, GPT1_3 (pin 30)

- PWM, GPT1_2 (pin 31)

- CAN, QT4_1 (pin 6)

- CAN, QT4_2 (pin 9)

- CAN, GPT1_CLK (pin 25)

- Audio, SPDIF_EXTCLK (pin 16)

- Audio, SPDIF_LOCK (pin 17)

- Audio, 1:TX_BCLK (pin 26)

- Audio, 1:TX_SYNC (pin 27)

- Audio, 3:MCLK (pin 30)

- Audio, 3:TX_DATA (pin 31)

i'm wondering if your flex will fit tight in the 609-1788-1-ND connector used on the beta test setups? that connector is a pressure fit, it looks like, whereas yours has a lock tab which you mention helps grip it. i don't want to solder flex to teensy until i decide to dedicate a teensy to the breakout.

I don't know yet. I still have to get my hands on one of those pressure fit connectors to test it with the flex cable. The datasheet indicates a recommended thickness of 3.0 ± 0.05 mm and the flex cable is 2.6 mm thick. That's a 0.35 mm discrepency, so I think it could probably go either way. I could also see about getting 3.0 mm flex cables made from a different supplier.

I've been considering including one of those connectors (609-1788-1-ND) with the Socket Kit (assuming that it fits ok), but I'm not sure yet. Using the flex cable without soldering it to the Teensy means that the USB host port can't be used at all. Since all the other headers get (permanently) soldered to the Teensy, I thought a tiny flex cable would be alright too as a permanent addition. The Socket Kit is more about being able to swap one Teensy for another than about keeping the Teensy intact. I could also see about using an 8-pin flip connector on the underside of the Teensy, but I'm worried about being able to anchor it to those super-thin grounding pads. So, I'm not sure yet. What do you think?

another thing i wonder about is the usb-a anchor pins being that close to the edge of the board. i've never had a board of any type with usb that far forward on the edge and it seems to me it might have too much stress crack potential. maybe not, maybe just lack of experience using a placement like that.

I don't think this is a risk. The installed USB-A port feels extremely strong. I suspect that under any kind of stress (bending, impact, etc.) the USB connector itself would be damaged well before the PCB would fracture. With this kind of connector, there's no contact or anchoring to the PCB past the mounting holes anyway.

Is the back filled with anything?

Dis you mean will the back of the card have anything on it? I wasn't planning on it. Anything useful you'd like to see there?

defragster

Senior Member+

Dis you mean will the back of the card have anything on it? I wasn't planning on it. Anything useful you'd like to see there?

Perhaps the more elaborate PIN table like KurtE's color coded rather than hogging up the front with wonderful details crowding out the common stuff?

View attachment 17443

Things get really smashed when adding the details - here is quick edit done for the T_4 card when the SPI pins noted as missing:

Last edited:

KurtE

Senior Member+

It is always difficult to know how much information to put on card like, this... For example the one that ships with Teensy is great for a lot of things, but I often go to my spreadsheet for some of the details that are not on the CARD... But having too much data can also be bad for some people.

For example at times, I want to know what the Actual underlying pin is, as maybe I need to do something special, or maybe someone wants to find a port with maybe 8+ pins that they hope they can update quickly.

Then there are things like FlexIO - This could be possibly interesting to different people. For example I have a beginning of a library: https://github.com/KurtE/FlexIO_t4

Which is setup to use these pins and the underlying FlexIO system. With it, I can currently create a Serial Port, using these pins, and I have a version of SPI that can work on these pins...

Note: with T4 there are 3 FLEXIO ports, which each of which can control certain pins. And also each have a certain number of timers and shift registers... And so you might need to both know that a pin is supported on one or more FlexIO objects and which ones... At some point hope to integrate some of the underlying code into core\teensy4, and then maybe migrate the Serial stuff to be put into maybe something like SoftwareSerial...

For example at times, I want to know what the Actual underlying pin is, as maybe I need to do something special, or maybe someone wants to find a port with maybe 8+ pins that they hope they can update quickly.

Then there are things like FlexIO - This could be possibly interesting to different people. For example I have a beginning of a library: https://github.com/KurtE/FlexIO_t4

Which is setup to use these pins and the underlying FlexIO system. With it, I can currently create a Serial Port, using these pins, and I have a version of SPI that can work on these pins...

Note: with T4 there are 3 FLEXIO ports, which each of which can control certain pins. And also each have a certain number of timers and shift registers... And so you might need to both know that a pin is supported on one or more FlexIO objects and which ones... At some point hope to integrate some of the underlying code into core\teensy4, and then maybe migrate the Serial stuff to be put into maybe something like SoftwareSerial...

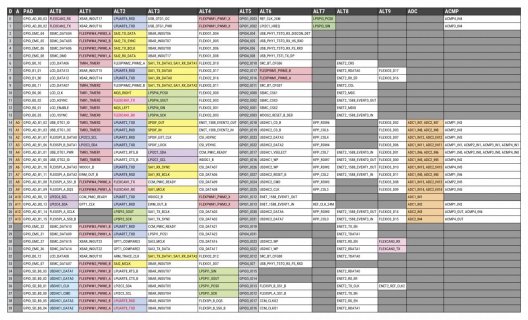

Ok, this is a bit of a tangent, but...

I made a pin mux table based on section 9.1.1 (pages 289-316) of the i.MX RT1060 Processor Reference Manual.

i.MX RT1060 Pin Mux Table

CSV (zipped): View attachment i.MX RT1060 Pins.csv.zip

Teensy 4.0 Pins Mux Table

CSV (zipped): View attachment Teensy 4.0 Pins.csv.zip

PDF: View attachment Teensy 4.0 Pins.pdf

I made a pin mux table based on section 9.1.1 (pages 289-316) of the i.MX RT1060 Processor Reference Manual.

i.MX RT1060 Pin Mux Table

CSV (zipped): View attachment i.MX RT1060 Pins.csv.zip

Teensy 4.0 Pins Mux Table

CSV (zipped): View attachment Teensy 4.0 Pins.csv.zip

PDF: View attachment Teensy 4.0 Pins.pdf

Last edited: