Hi guys, very first Arduino programming and probably not the easiest to start with, but went for it nevertheless ... did the best I could, so bare with me please ...

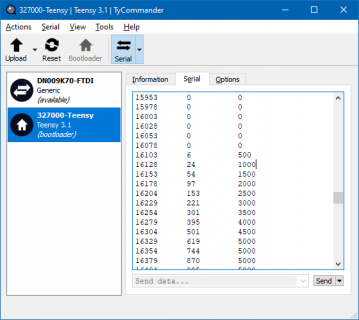

The idea is to replicate the control panel of an older milling machine and adding the same function to another machine w/o power feed. Started out on an Arduino Uno, but both displays I've tried were disturbing the running of the stepper motor. Moving to a Teensy 3.2 solved that issue and it basically works as expected, with two quirks:

1. One of the directions, when sign = -1, does not work after moving to Teensy, it worked on the Arduino - stepper runs at some arbitrary speed and cannot be controlled

2. When pushing Fast Forward (FF) the stepper seems to want to start at first in both directions at the same time, so there is maybe halve a second of back and fort struggle, then it is running as it should (added Debounce to that button, but doesn't help the problem)

The control panel involves a joystick switch that sets left or right, then the actual Start button, a Stop button and the FF button. And a pot to set the feed rate, which is being displayed.

Unfortunately I wasn't able to achieve what I wanted by using only one stepper library. Ended up using AccelStepper for the regular feed, since no need for acceleration there. For FastForward, to move the table at max speed left or right, I added Teensystep.

So I'd be happy if somebody can direct me to solve the two listed issues. On top of that, if some additional tuning could be done, that would be a great bonus. Of interest would be:

- setting a different value for deceleration when stopping FF

- transitioning from regular feed to FF and back without the stepper stopping - I assume that's kind of a complete rewrite though

- eventually using just one of the two stepper libraries (doesn't seem to be an issue though, but for the sake of elegance and knowledge)

The idea is to replicate the control panel of an older milling machine and adding the same function to another machine w/o power feed. Started out on an Arduino Uno, but both displays I've tried were disturbing the running of the stepper motor. Moving to a Teensy 3.2 solved that issue and it basically works as expected, with two quirks:

1. One of the directions, when sign = -1, does not work after moving to Teensy, it worked on the Arduino - stepper runs at some arbitrary speed and cannot be controlled

2. When pushing Fast Forward (FF) the stepper seems to want to start at first in both directions at the same time, so there is maybe halve a second of back and fort struggle, then it is running as it should (added Debounce to that button, but doesn't help the problem)

The control panel involves a joystick switch that sets left or right, then the actual Start button, a Stop button and the FF button. And a pot to set the feed rate, which is being displayed.

Unfortunately I wasn't able to achieve what I wanted by using only one stepper library. Ended up using AccelStepper for the regular feed, since no need for acceleration there. For FastForward, to move the table at max speed left or right, I added Teensystep.

So I'd be happy if somebody can direct me to solve the two listed issues. On top of that, if some additional tuning could be done, that would be a great bonus. Of interest would be:

- setting a different value for deceleration when stopping FF

- transitioning from regular feed to FF and back without the stepper stopping - I assume that's kind of a complete rewrite though

- eventually using just one of the two stepper libraries (doesn't seem to be an issue though, but for the sake of elegance and knowledge)

Code:

#include "TeensyStep.h"

#include <AccelStepper.h>

#include <LedControl.h>

#include "Bounce2.h"

Stepper ff(1, 2); // TeensyStep STEP pin: 1, DIR pin: 2

RotateControl controller; // Use default settings

AccelStepper stepper(1, 1, 2);

LedControl lc=LedControl(11,13,10,1);

// Define analog pot input pin

#define SPEED_PIN 9

// Define maximum and minimum speed in steps per second (scale pot to these)

#define MAX_SPEED 2400

#define MIN_SPEED 240

// switches

#define BUTTON_PIN_1 17

Bounce FFbutton = Bounce();

void setup()

{

pinMode(18, INPUT_PULLUP); // Right switch

pinMode(14, INPUT_PULLUP); // Left switch

pinMode(15, INPUT_PULLUP); // Stop button

pinMode(16, INPUT_PULLUP); // Start button

pinMode(BUTTON_PIN_1, INPUT_PULLUP); // FF button

FFbutton.attach(BUTTON_PIN_1);

FFbutton.interval(30);

stepper.setMaxSpeed(13300);

lc.shutdown(0,false); // MAX72XX wake up

lc.setIntensity(0,4); // set brightness

lc.clearDisplay(0);

controller.stop();

}

void loop()

{

static float current_speed = 0.0; // Holds current motor speed in steps/second

static int feed = 0; // Holds current feed speed in mm/min

static int analog_read_counter = 1000; // Counts down to 0 to fire analog read

static char sign = 0; // Holds -1, 1 or 0 to turn the motor on/off and control direction

static int analog_value = 0; // Holds raw analog value.

// Update the Bounce instances :

FFbutton.update();

// Get the updated value :

int value1 = FFbutton.read();

// if a switch is pushed down (0), set the sign value appropriately

if ((digitalRead(18) == 0) && (digitalRead(16) == 0)) { // Right switch + Start button

sign = 1;

}

else if ((digitalRead(14) == 0) && (digitalRead(16) == 0)) { // Left switch + Start button

sign = -1;

}

else if (digitalRead(15) == 0) { // Stop button

sign = 0;

controller.stop(); // teensystep stop

}

else if ((digitalRead(18) == 1) && (digitalRead(14) == 1)) { // Right switch + Left Switch off

sign = 0;

controller.stop(); // teensystep stop

}

else if ((digitalRead(18) == 0) && value1 == LOW ) { // Right switch + FF button

sign = 0;

ff.setMaxSpeed(13300); // teensystep stp/s

ff.setAcceleration(8000); // teensystep stp/s^2

controller.rotateAsync(ff); // teensystep start

}

else if ((digitalRead(14) == 0) && value1 == LOW ) { // Left switch + FF button

sign = 0;

ff.setMaxSpeed(-13300); // teensystep stp/s

ff.setAcceleration(8000); // teensystep stp/s^2

controller.rotateAsync(ff); // teensystep start

}

// read pot every so often

if (analog_read_counter > 0) {

analog_read_counter--;

}

else {

analog_read_counter = 1000;

analog_value = analogRead(SPEED_PIN); // read pot (from 0 to 1023)

stepper.runSpeed(); // give stepper a chance to step if it needs to

current_speed = sign * (((analog_value/1023.0) * (MAX_SPEED - MIN_SPEED)) + MIN_SPEED); // calculate stepper speed

stepper.setSpeed(current_speed); // Update the stepper to run at this new speed

feed = 0.09 * (((analog_value/1023.0) * (MAX_SPEED - MIN_SPEED)) + MIN_SPEED); // calculate feed rate

lc.setDigit(0,2,(feed / 100),false);

lc.setDigit(0,1,((feed % 100) / 10),false);

lc.setDigit(0,0,(feed % 10),false);

}

stepper.runSpeed(); // run the stepper at a constant speed

}