Hello everyone,

I've been using the teensy 3.2 for a while and recently started using analog inputs.

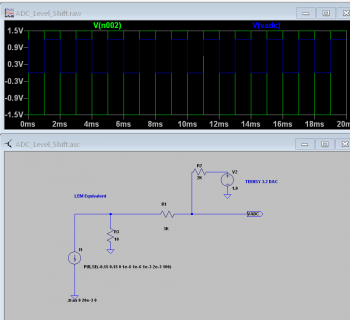

I'm facing reading a bipolar signal +/- 1.5 volt generated by a LEM current transducer.

The LEM reads max +/- 300A and outputs +/-150mA over a 10R resistor, 1:2000 (1mA = 2A)

What is the best/advised way to read and adapt this LEM output signal into the teensy on A0 ?

I have found 3 options sofar:

#1: Using a low noise opamp according to this: https://masteringelectronicsdesign.com/measure-a-bipolar-signal-with-an-arduino-board/

#2: using a 10k/10k voltage divider between 3v3 and GND and superimposing the LEM output onto the midpoint using a resistor

#3: using a 10k/10k voltage divider between 3v3 and GND and connecting the LEM signal using a 10uF capacitor to the midpoint

Any suggestion or recommendations ?

Regards,

Paul

I've been using the teensy 3.2 for a while and recently started using analog inputs.

I'm facing reading a bipolar signal +/- 1.5 volt generated by a LEM current transducer.

The LEM reads max +/- 300A and outputs +/-150mA over a 10R resistor, 1:2000 (1mA = 2A)

What is the best/advised way to read and adapt this LEM output signal into the teensy on A0 ?

I have found 3 options sofar:

#1: Using a low noise opamp according to this: https://masteringelectronicsdesign.com/measure-a-bipolar-signal-with-an-arduino-board/

#2: using a 10k/10k voltage divider between 3v3 and GND and superimposing the LEM output onto the midpoint using a resistor

#3: using a 10k/10k voltage divider between 3v3 and GND and connecting the LEM signal using a 10uF capacitor to the midpoint

Any suggestion or recommendations ?

Regards,

Paul