Magnificent. A remarkable effort and an impressive result.

Thanks!

If you can spare the time, I would love to read about your thoughts and problems as you went through the phases from initial ideas/conceptions to experiment and testing.

There was many phases. I first tried using a motor and a Bag valve mask like some open source ventilators out there but it didn't seem reliable. Then I bought a few air mattress inflators and found out the AC version was powerful enough for the ventilator.

Then I needed to learn lots of physics like fluid dynamics, thermodynamics and aerodynamics.

I added 2 flow sensors. The flow sensors I'm using are car flow sensors. I needed to learn a lot about flow sensors and how to calibrate them.

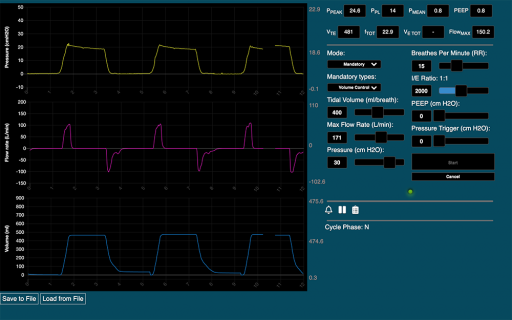

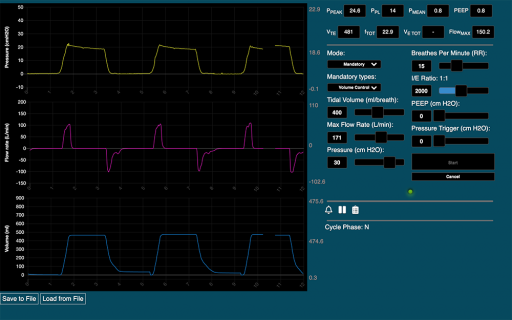

I built software for curve fitting to build formulas to translate the flow sensor signals into flow rates.

On the controller side I first I used Arduino Uno as the main controller but eventually I realized that it's too slow to handle so many calculations and control parts so I decided to upgraded to the Teensy 4.1.

For the pressure sensor I'm using the MPX10.

For flow rate calibration I'm using a Pitot tube powered by MPXV7002.

Here is a few links I used for reference:

https://www.instructables.com/id/The-Pandemic-Ventilator/

https://emergency-vent.mit.edu/

https://github.com/jcl5m1/ventilator

https://op-vent.stanford.edu/

PuritanBennett980Ventilator_OperatorsManual_en_US_PT00109658A00.pdf

Design specifications for the Medtronic PB560 ventilator system

What is the pressure generator? How is this controlled? Have you tried any failure modes yet, to see what the effects of failures in the system would be?

Currently I'm using on AC powered mattress inflators. I'm using a triac circuit to control the motor and it's power.

I did many tests like adding different lung simulators with different elastic strength and I also added valves to the output to simulate pinched pipes are a pipe disconnection.

There is a set of alarms you can set that will warn you when something goes wrong.

If for example a pipe gets disconnected the software doesn't have much it can do but just alarm the medical staff.

Are you employed in the bio-engineering industry, or do you fancy a career in that direction?

Currently I don't work at all in the bio-engineering industry but I guess if this ventilator works out I will open a ventilator manufacturing company.

If you have any other questions please let me know!