Hi All,

I'm looking for some very general guidance on how to convert lineal sensor measurements (10-bit) into curves of varying intensity. I have a set of force sensing resistors that I'm making a MIDI instrument from and I want to try some different ways of tuning their sensitivity. I've done some simple stuff like raising the lowest available value and lowering the max value needed to clip at the highest midi note velocity but it feels like I need something more precise. This link shows how a commercial product applies logarithmic and exponential curves to the data to change the sensitivity:

https://www.noterepeat.com/products/akai-professional/mpc2500?id=146

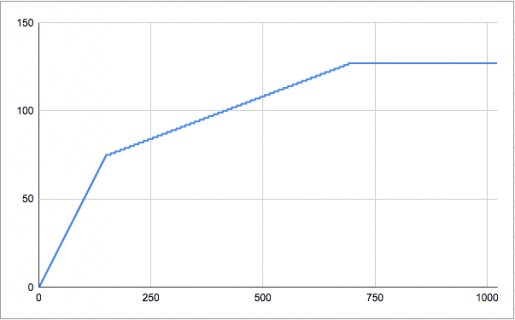

I looked through my notes and found a formula that I'd use for some digital potentiometer stuff but it was just for calculating value in a spreadsheet and would use floating point math in it's current state. It takes percentages from 0 to 1.0 and converts them to a value that fits a curve of some intensity. I can't find the original reference but either the .0125 or 81 could be changed to adjust the curve intensity.Of course this only achieves a log curve (lower sensitivity) not a Exp (for higher sensitivity).

=0.0125 *(81^linearpercentage) - 0.0125

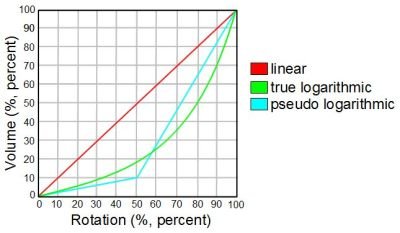

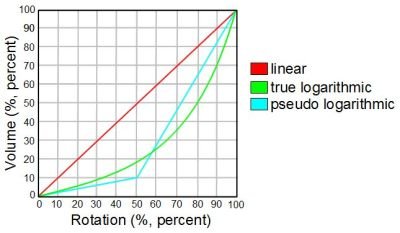

There's also the possibility of "pseudo-log" (borrowing a term from the analog world) where the curve is simplified to a couple of straight lines that approximate said curve. This is what log potentiometers do to ease manufacturing. Like this:

I'm reading 16 analog values, conditioning them, and returning for usbMIDI to send them out when back in the loop. This is done in an ISR so I want to keep the math tight. Some details:

So I'm just looking for some general brainstorm ideas on how more experienced people might do something like this.

Brian

I'm looking for some very general guidance on how to convert lineal sensor measurements (10-bit) into curves of varying intensity. I have a set of force sensing resistors that I'm making a MIDI instrument from and I want to try some different ways of tuning their sensitivity. I've done some simple stuff like raising the lowest available value and lowering the max value needed to clip at the highest midi note velocity but it feels like I need something more precise. This link shows how a commercial product applies logarithmic and exponential curves to the data to change the sensitivity:

https://www.noterepeat.com/products/akai-professional/mpc2500?id=146

I looked through my notes and found a formula that I'd use for some digital potentiometer stuff but it was just for calculating value in a spreadsheet and would use floating point math in it's current state. It takes percentages from 0 to 1.0 and converts them to a value that fits a curve of some intensity. I can't find the original reference but either the .0125 or 81 could be changed to adjust the curve intensity.Of course this only achieves a log curve (lower sensitivity) not a Exp (for higher sensitivity).

=0.0125 *(81^linearpercentage) - 0.0125

There's also the possibility of "pseudo-log" (borrowing a term from the analog world) where the curve is simplified to a couple of straight lines that approximate said curve. This is what log potentiometers do to ease manufacturing. Like this:

I'm reading 16 analog values, conditioning them, and returning for usbMIDI to send them out when back in the loop. This is done in an ISR so I want to keep the math tight. Some details:

- The data is 10 bit as mentioned above

- The range is narrower than 0-1023 because I set a threshold at the bottom for noise and a pull down resistor prevents getting fully to 1023

- The final value needs to be from 0-127 for the midi standard

- I'd like to acheive close to the full 127 values of precision. I think the MPC product I linked to uses 10 values which is fine for a simple drum machine but I'm using real time pressure manipulation for additional expressive controls

So I'm just looking for some general brainstorm ideas on how more experienced people might do something like this.

Brian