#include "stepper_n_encoder_v2.h"

void doincrement(bool adir);

//// imperial 32 TPI

// int N = 293;

// int D = 2000;

//// imperial 8 TPI

// int N = 293;

// int D = 500;

//// imperial 6 TPI

// int N = 781;

// int D = 1000;

// Note: 17 May 2022, N & D were calculated off line. The value of microsteps is embedded in the ratio. To

// add one's own feeds or threads, we need to calculate using the required # of microsteps! This functionality

// is not in the code base yet.

#ifdef imperial

uint16_t myidx = 1;

float TPI = impthread[myidx].tpi;

int N = impthread[myidx].N;

int D = impthread[myidx].D;

int ustep = impthread[myidx].ustep; // added for future capability

float tenpitch_error_percent = impthread[myidx].error;

#endif

OneShotTimer t1(PIT); // for stepper pulse

OneShotTimer t2(PIT); // for measuring speed.

// XPT2046_Touchscreen ts(TOUCH_CS);

// ILI9341_t3n tft = ILI9341_t3n(TFT_CS, TFT_DC, TFT_RST, TFT_MOSI, TFT_SCK, TFT_MISO);

void onEncoderChanged(int value, int delta)

{

// volatile int mydelta = -delta;

if (delta > 0)

{

if (delta > 1)

{

Serial.printf("fault! delta = %i\n", delta);

errorcount += 1;

}

else

{

// delta = 1

myacc = myacc + delta * N;

if (myacc >= D) // works for positive accumulation only

{

myacc = myacc - D;

mydir = CCW;

doincrement(mydir);

}

}

}

if (delta < 0)

{

if (delta < -1)

{

Serial.printf("fault! delta = %i\n", delta);

errorcount += 1;

}

else

{

// delta = -1

myacc = myacc + delta * N;

if (myacc <= D)

{

myacc = myacc + D;

mydir = CW;

doincrement(mydir);

}

}

}

val1 = value;

//Serial.printf("Count = %i\n", value);

}

// void onEncoderError() don't know how it is used, nor what to look for!

void pulseme() // turns off stepper pulse after time out

{

digitalWriteFast(PUL, LOW);

// digitalWriteFast(LED_BUILTIN, LOW);

}

void doincrement(bool adir) // sets direction and turns on stepper pulse

{

digitalWriteFast(DIR, adir); // set direction

delayNanoseconds(100); // can improve stepper speed by doing this, but is dangerous...

digitalWriteFast(PUL, HIGH);

t1.trigger(steplen); // switch off after steplen us (2us)

}

void myms() // xxms timer callback for estimating spindle speed and step rate

{

val2 = (uint32_t)SpindleEnc.getValue(); // read encoder for current position

// we know the time was 20 ms

cps = 50.0f * ((int)val2 - valstart) / (float)encoder_resolution;

; // rev per second 50 = 1/0.02

sps = cps * (float)encoder_resolution * (float)N / (float)D; // steps/second

myrpm = -cps * 60.0f;

timeout = true;

}

void readconsole()

{

if (Serial.available())

{

int incomingByte = Serial.read(); // read the incoming byte

char c = (char)incomingByte;

// Parse the command.

if ((c != '\n') & (c != '\r'))

{

Serial.println();

Serial.print(F("key pressed: "));

if (c == ' ')

Serial.println(F("[space]"));

else

Serial.println(c);

if (c == 'r') // reset the counter

{

SpindleEnc.setValue(0); // wait til we get the right syntax!

Serial.printf("Reset spindle counter to 0\n");

} // add more commands as you see fit

}

}

}

void setup()

{

while (!Serial && millis() < 4000)

;

if (CrashReport)

Serial.println(CrashReport);

for (int i = 5; i < 8; i++) pinMode(i, OUTPUT); // init these pins to outputs

t1.begin(pulseme); // set up t1 callback function

t2.begin(myms); // set up t2 callback function

digitalWriteFast(DIR, CW); // sets direction of rotation LOW =CW, HIGH=CCW

digitalWriteFast(ENA, LOW); // active low signal, enables the stepper controller

// Use luni's SW encoder

SpindleEnc.begin(0, 1, CountMode::full); // encoder on pins 0,1 count all e3dges of the quadrature signal

SpindleEnc.attachCallback(onEncoderChanged);

myacc = 0; // Bresenham accumulator

oldrpm = 0.0f;

timeout = true; // so we start measuring speed right away

// if (0){ // prevent all tft writess for debug!!!

// if (!initMyDisplay(3))

// {

// Serial.println("Display failed to initialize");

// while(1);

// }

// if (!mainscreen())

// {

// Serial.println("Failed to send first message to display");

// while(1);

// }

// }

errorcount = 0;

displaycount = 0;

first = true;

// Eventually all this will be selected via the touch panel

Serial.printf("TPI = %3.1f, usteps/step = %i\n", TPI, ustep);

Serial.printf("N = %i, D = %i\n", N, D);

Serial.printf("Ten pitch error as per cent of pitch = %4.2f\n", tenpitch_error_percent);

}

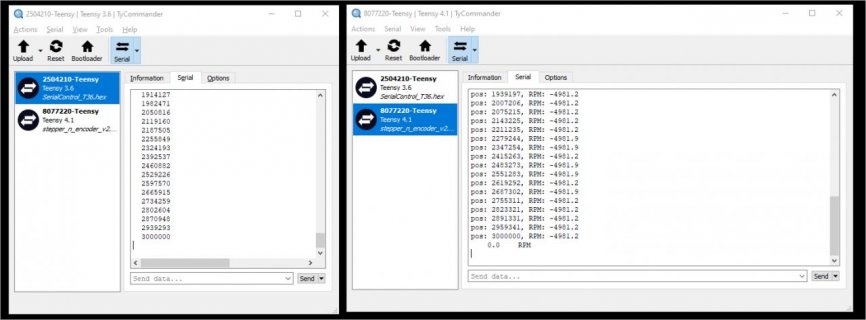

void loop()

{

if (timeout) // if no timeout, skip this

{

timeout = false; // determine how many counts we get in 20ms, this is the base for a speed estimate

t2.trigger(20ms); // set timer to go off in 20ms

valstart = val1; // save current position

}

if ((myrpm == 0.0f) && (first))

{

Serial.printf("%7.1f%\tRPM\n", -myrpm); // there's a zero bug of some sort

// displayRPM(-myrpm);

first = false;

}

if (myrpm != 0)

{

first = true;

Serial.printf("pos: %d, RPM: %7.1f\n", SpindleEnc.getValue(), myrpm);

// displayRPM(myrpm);

}

delay(200);

// readconsole();

}