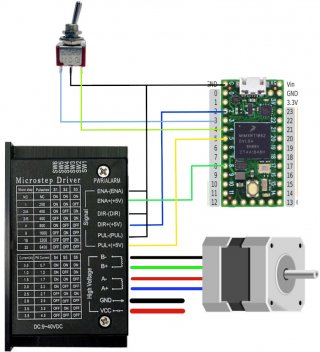

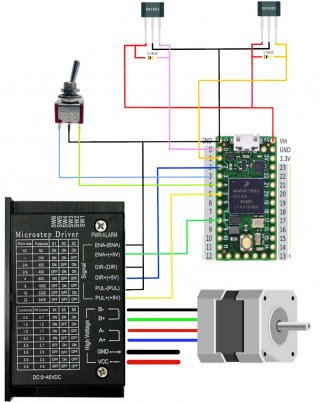

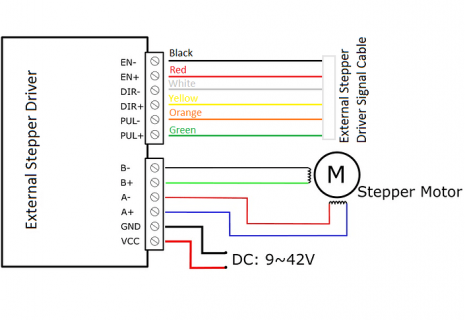

I need to connect a 3 position momentary toggle switch to run a stepper motor in either forward or reverse. I have a TB600 driver and a NEMA23 stepper bipolar motor and a teensy 3.2 board. I'm not sure how to wire it or if this code will work, I can't seam to find a good example of this. Any help would be appreciated.

Code:

const int stepPin = 5;

const int dirPin = 2;

const int enPin = 8;

void setup() {

pinMode(stepPin,OUTPUT);

pinMode(dirPin,OUTPUT);

pinMode(enPin,OUTPUT);

digitalWrite(enPin,LOW);

}

void loop() {

digitalWrite(dirPin,HIGH); // Enables the motor to move in a particular direction

for(int x = 0; x < 800; x++) {

digitalWrite(stepPin,HIGH);

delayMicroseconds(500);

digitalWrite(stepPin,LOW);

delayMicroseconds(500);

}

delay(1000); // One second delay

digitalWrite(dirPin,LOW); //Changes the direction of rotation

for(int x = 0; x < 800; x++) {

digitalWrite(stepPin,HIGH);

delayMicroseconds(500);

digitalWrite(stepPin,LOW);

delayMicroseconds(500);

}

delay(1000);

}