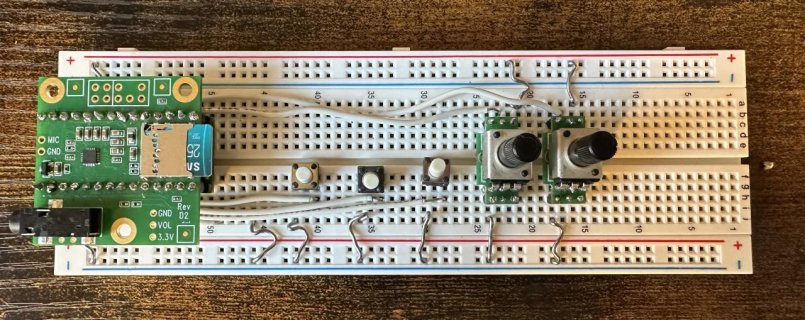

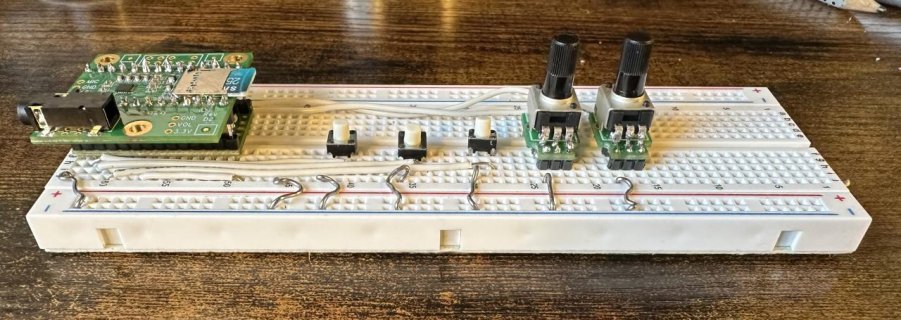

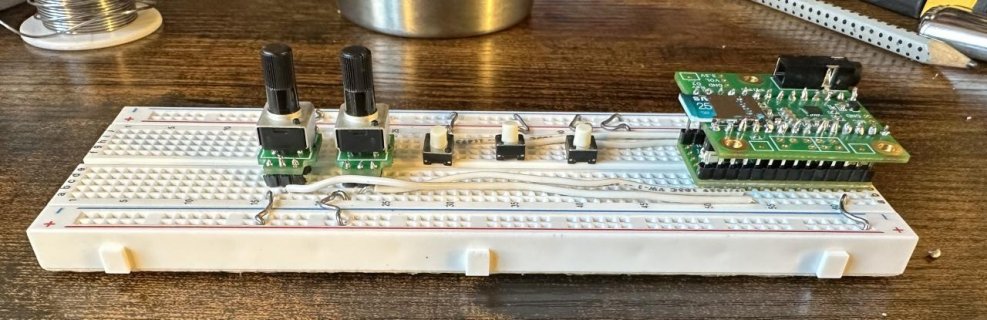

I’ve been attempting to assemble and use the teensy audio tutorial from the unbuilt audio tutorial parts and I've been running into some issues trying to pass the hardware test.

Using the hardware test program, I’ve been able to get the standard beeps from the serial monitor but the buttons and knobs don’t register inputs, and the knob inputs appear to come somewhat inconsistently when the board is moved, but I cannot figure out what potential loose connections could be causing this issue. I checked the schematic placements for the wires quite a few times. Does anybody know of any common errors in doing this kind of assembly that could be causing this issue or if there’s anything present in the attached images?

I apologize if there's something I may have absolutely gutted in this assembly, I'm very much new to this.

Using the hardware test program, I’ve been able to get the standard beeps from the serial monitor but the buttons and knobs don’t register inputs, and the knob inputs appear to come somewhat inconsistently when the board is moved, but I cannot figure out what potential loose connections could be causing this issue. I checked the schematic placements for the wires quite a few times. Does anybody know of any common errors in doing this kind of assembly that could be causing this issue or if there’s anything present in the attached images?

I apologize if there's something I may have absolutely gutted in this assembly, I'm very much new to this.