Constantin

Well-known member

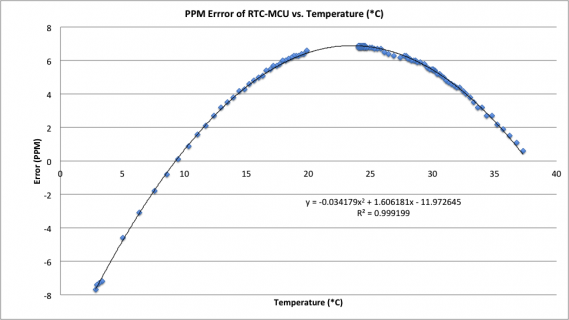

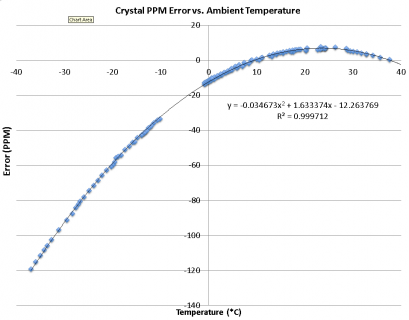

As some of you might recall, I have been experimenting with temperature swings lately with the help of a HTU21 humidity / temperature sensor, the cold winter weather, and a Teensy 3. I had a pretty good experience with the crystal, where I could get the RTC to run at apparently better than 0.5PPM accuracy, simply by periodically polling the HTU21 to see what the temperature was and then applying an open-loop correction factor to the Teensy RTC trim to minimize the temperature-induced error (see second chart to right below).

However, other components like transformers similarly change their output as a function of temperature. Tonight, I did a preliminary test to see what the likely magnitude of the temperature influence is with the voltage transformers I am using for power measurements. Originally, I wanted to do this using two Teensy's (oe at room temp as a control, the other cooled).

Apparently one cannot have two serial monitor windows open at once on a single CPU (at least on a Mac, on Win 7 Pro, the serial window wouldn't open at all, even though I could upload sketches), so the software on both units will have to be revised to write time-stamped data to SD disk. Or, I'll abuse a Yokogawa at work for a day. (which would also do wonders for offset and gain calculations).

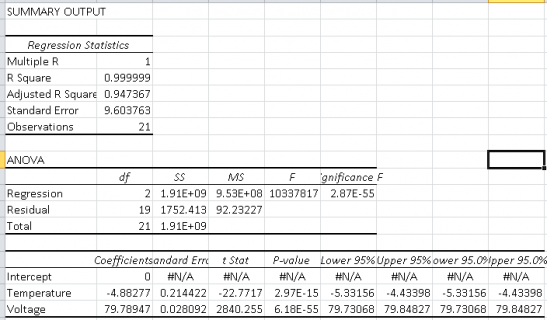

Anyhow, have a look and a laugh. I need to sample a lot more data using better means, but compensating for temperature influences on voltage-transformer- or current transformer-based measurements seems to be pretty justifiable. The regression analysis here [left image]was run backwards to establish the impact on the ADC output. More and better testing is required but the R2, t-stat, p, and F values pretty much speak for themselves.

However, other components like transformers similarly change their output as a function of temperature. Tonight, I did a preliminary test to see what the likely magnitude of the temperature influence is with the voltage transformers I am using for power measurements. Originally, I wanted to do this using two Teensy's (oe at room temp as a control, the other cooled).

Apparently one cannot have two serial monitor windows open at once on a single CPU (at least on a Mac, on Win 7 Pro, the serial window wouldn't open at all, even though I could upload sketches), so the software on both units will have to be revised to write time-stamped data to SD disk. Or, I'll abuse a Yokogawa at work for a day. (which would also do wonders for offset and gain calculations).

Anyhow, have a look and a laugh. I need to sample a lot more data using better means, but compensating for temperature influences on voltage-transformer- or current transformer-based measurements seems to be pretty justifiable. The regression analysis here [left image]was run backwards to establish the impact on the ADC output. More and better testing is required but the R2, t-stat, p, and F values pretty much speak for themselves.

Attachments

Last edited: