Hello,

I am considering using Teensy 3.1 inside of a (small scale) commercial product. This seems to make sense in terms of time and cost for a short run product.

The one major hurdle I need to resolve is breaking out the USB connection. I plan to have a USB isolator chip and a separate PCB with a USB type B jack for the main USB connection.

Using the built-in micro USB connector on the Teensy 3.1 doesn't make sense in this case.

Has anyone else done something similar and have suggestions?

The options I have considered are:

* Use a bare wire micro-USB extender with the Teensy jack (hard to find and/or expensive)

* Remove the Teensy USB jack and solder wires to the pads (unworkable)

* Use the test pads on the bottom of the board when mounting to the main PCB (work intensive)

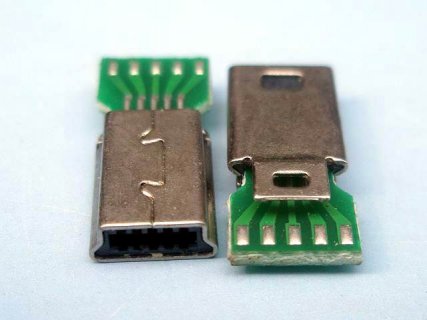

* Make a custom PCB "mate" that plugs in to the micro USB jack and then exposes pins down to the main PCB for soldering (extravagant, but most workable into production)

Any suggestions or comments?

Thanks

JK

I am considering using Teensy 3.1 inside of a (small scale) commercial product. This seems to make sense in terms of time and cost for a short run product.

The one major hurdle I need to resolve is breaking out the USB connection. I plan to have a USB isolator chip and a separate PCB with a USB type B jack for the main USB connection.

Using the built-in micro USB connector on the Teensy 3.1 doesn't make sense in this case.

Has anyone else done something similar and have suggestions?

The options I have considered are:

* Use a bare wire micro-USB extender with the Teensy jack (hard to find and/or expensive)

* Remove the Teensy USB jack and solder wires to the pads (unworkable)

* Use the test pads on the bottom of the board when mounting to the main PCB (work intensive)

* Make a custom PCB "mate" that plugs in to the micro USB jack and then exposes pins down to the main PCB for soldering (extravagant, but most workable into production)

Any suggestions or comments?

Thanks

JK