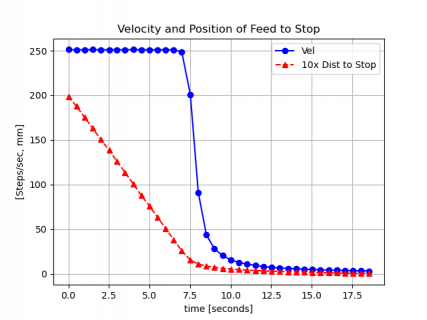

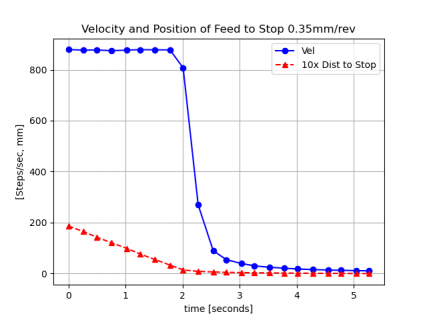

I have an electronic lead screw (ELS) project that I completed a couple of years ago. It's probably 3000+LOC. I'm using a Teensy4.1 and it's been working flawlessly. I'd like to augment the capabilities, and I'm finding it tough to log the data that I need, to prove to myself that the ELS is working as I expect. I'm adding an exponential deceleration to my stepper so that the carriage stops with little to no overshoot. I need to test that it is working with the right profile.

The Arduino IDE output window is grossly deficient, I need to save many thousands of points, but it will not allow copying that many lines. It would be useful to log the data on the usbserial port, which is already connected to my Mac.

I tried

I was able to capture some data, but unfortunately not all of it. Might be my terminal settings, I will check. It seemed I captured only a small fraction of the data. Roughly I want to capture 20,000 points, basically 20mm of travel sampled every micron. I'm getting about 50 lines of data.

What is the correct baud rate for the connection?

All that I'm trying to log is the spindle velocity, number of cycles, and the position of the carriage, or in code terms:

In screen, I'm not getting carriage returns, only line feeds. But it is being interpreted correctly in the IDE window. Might need a \r?

Edit: Using \r messes up both the IDE and the screen output.

However, using the screen app, captures the usbmodem. I found a way to release it, but it's not something I want to do long term. Is there a way to promiscuously monitor the port?

Is there something less painful to do? Been beating my head against a wall, and thought I'd ask if there was something more productive to try!

The Arduino IDE output window is grossly deficient, I need to save many thousands of points, but it will not allow copying that many lines. It would be useful to log the data on the usbserial port, which is already connected to my Mac.

I tried

Code:

% screen -port /dev/cu.usbmodem119047801 115200What is the correct baud rate for the connection?

All that I'm trying to log is the spindle velocity, number of cycles, and the position of the carriage, or in code terms:

C-like:

Serial.printf("%f, %i, %f\n", RPM, ARM_DWT_CYCCNT, ztogo);In screen, I'm not getting carriage returns, only line feeds. But it is being interpreted correctly in the IDE window. Might need a \r?

Edit: Using \r messes up both the IDE and the screen output.

However, using the screen app, captures the usbmodem. I found a way to release it, but it's not something I want to do long term. Is there a way to promiscuously monitor the port?

Is there something less painful to do? Been beating my head against a wall, and thought I'd ask if there was something more productive to try!