Bob Larkin

Well-known member

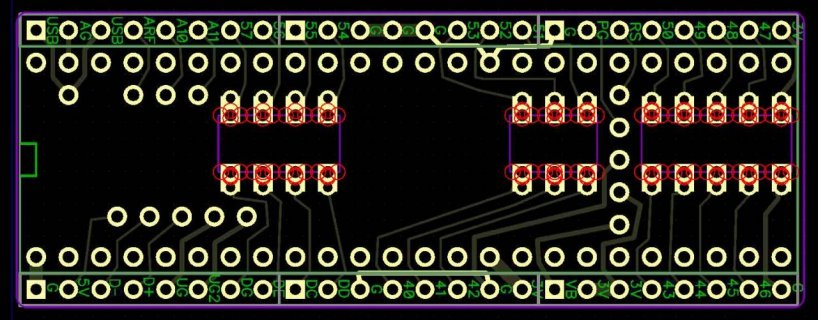

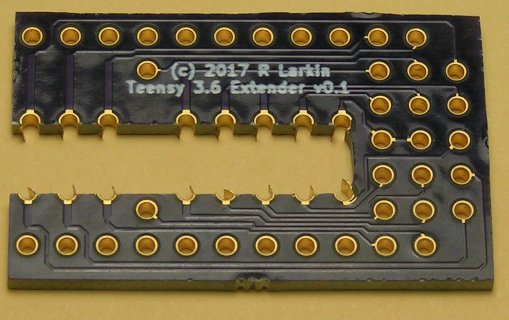

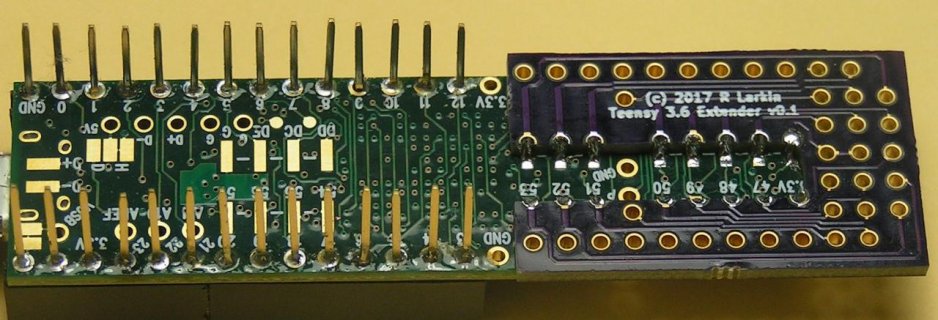

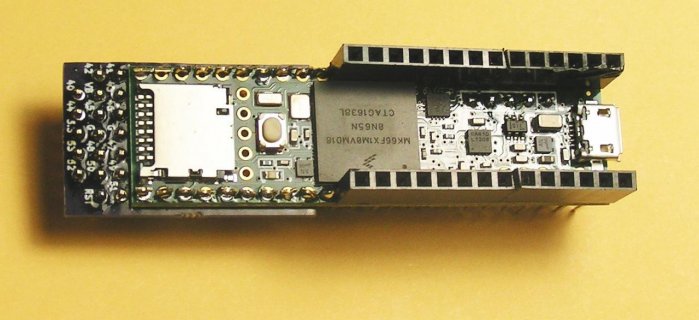

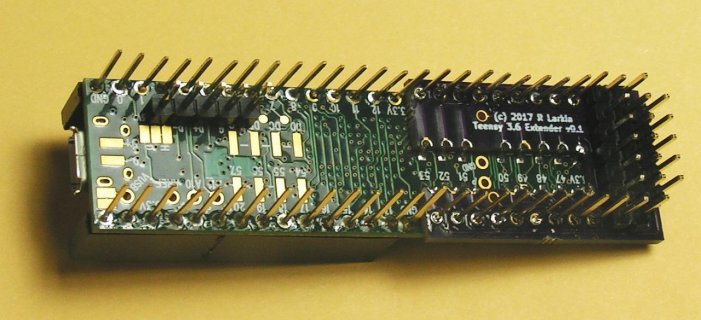

I've hunted but not found the answer. I need just a few more digital pins from the bottom pads of the T3.6. Frank B's Connector Board 3 for T3.2 would seem to do the job fine, if it fit. https://pcbs.io/share/46718

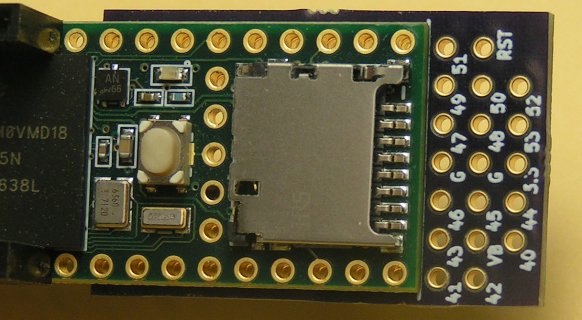

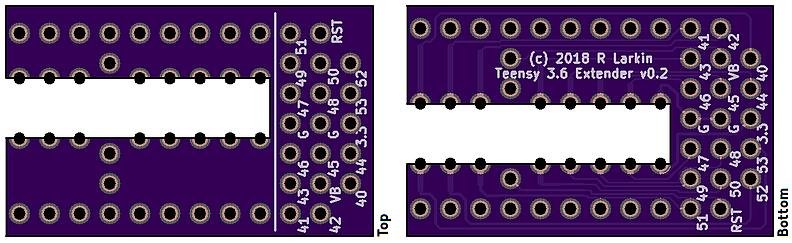

Is there a similar board, for the T3.6, that would connect to the pins under the SD card?

To get started, it appears that the 3.2 Connector Board could be used under the 3.6, bringing out pins 41, 43, 44, 45, 46, 47, 48, 49, 50 and 52. It would also need some insulating tape over some pins to prevent shorts. Has anybody done this?

Thanks, Bob

Is there a similar board, for the T3.6, that would connect to the pins under the SD card?

To get started, it appears that the 3.2 Connector Board could be used under the 3.6, bringing out pins 41, 43, 44, 45, 46, 47, 48, 49, 50 and 52. It would also need some insulating tape over some pins to prevent shorts. Has anybody done this?

Thanks, Bob